Welcome to the tutorial about SAP Work Center Capacity. This tutorial is part of the SAP PP training course. You will learn what is capacity in SAP PP, how to use capacity categories, the difference between available and required capacity, intervals of available capacity, usage of shifts in capacities and individual capacities. Also, we will discuss different units of measure for capacities and cumulation of capacities in hierarchies of work centers.

Welcome to the tutorial about SAP Work Center Capacity. This tutorial is part of the SAP PP training course. You will learn what is capacity in SAP PP, how to use capacity categories, the difference between available and required capacity, intervals of available capacity, usage of shifts in capacities and individual capacities. Also, we will discuss different units of measure for capacities and cumulation of capacities in hierarchies of work centers.

What is Capacity?

Capacity means capability to do certain work. In SAP, capacity is closely related with work centers, i.e. capability of a work center/machine to do certain operations. In general, capacity will be measured in “Time” unit. We can also use other units of measure depending on production business processes.

Role of Capacity in SAP PP

In SAP Production Planning, capacity data in work center is used for calculation of:

- Required capacity for an order or an operation

- Available capacity of a work center

Integration with Other Business Functions

SAP work centers are integrated with the following business functions (SAP modules):

- We can assign an HR object to a work center which will be helpful for determining qualification of an employee.

- For example, certain operations might need special skillsets like CNC Operator/programmer. We can assign this information to the work center.

- When a particular machine/work center is scheduled in PM order for maintenance activities, its capacity will be locked for production uses.

SAP Capacity Category

SAP capacity category is used to distinguish various capacities within a work center. If you want to maintain different capacities for labor and machine in a work center, we can define it by means of capacity categories:

- Machine Capacity

- Labor Capacity

Example

Consider a Lathe machine which requires 3 labor units to perform the operations and it is available 9 hours per day. In this case, we have the following capacities:

| Capacity Category | Available hours | No of Capacity | Total hours |

| Machine | 9 | 1 | 9 Hrs. |

| Labor | 9 | 3 | 27 Hrs. |

SAP Work Center Capacity

Available Capacity

In general, capacity means available hours of a machine or labor. These available hours excludes breaks or halt hours.

Assume that a Lathe machine is available in a production plant from 9 AM to 9 PM and there will be a break time of 2 hours for lunch and evening snacks. The capacity of the Lathe machine is calculated as follows:

Available Capacity = 12 Hours (Total hours) - 2 Hours (Break)

Available Capacity = 10 Hours

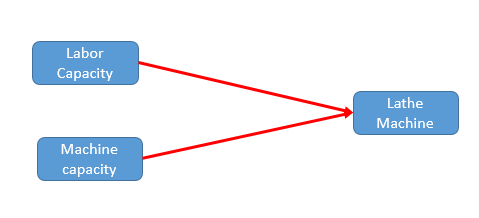

Required Capacity

Required capacity is hours required for a work center to produce a particular quantity of an assembly. The SAP system uses the following information to calculate required capacity for a work center:

- Capacity formula. It uses standard value key parameters (Basic tab of work center master data screen).

- Operation time in a production order. It uses time defined in routing operation for the base quantity.

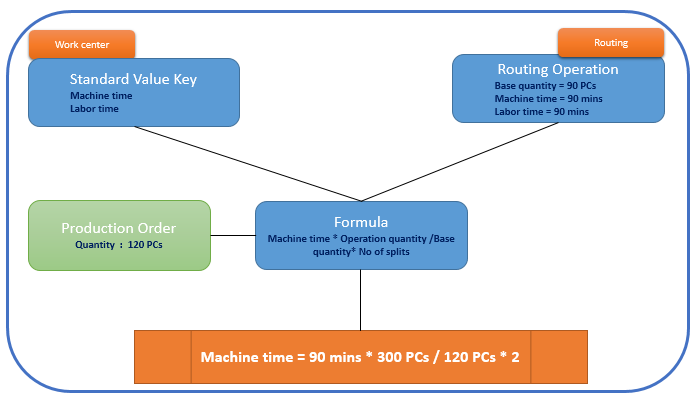

Example

A process in a steel cutting unit uses a machine called Plasma cutting with the following standard value parameters:

- Setup time

- Machine time

- Labor time

Let’s say in routing we have maintained the following times for the above parameters:

- Base Quantity: 120 PCs

- Setup time: 30 Mins

- Machine time: 90 Mins

- Labor time: 90 mins

Capacity formula defined for this machine is as follows:

Machine time * Quantity to be produced / Base quantity

When a production order for the quantity of 300 PCs is created, capacity is calculated as follows:

Required Capacity = 90 mins * 300 PCs / 120 PCs

Required Capacity = 225 mins

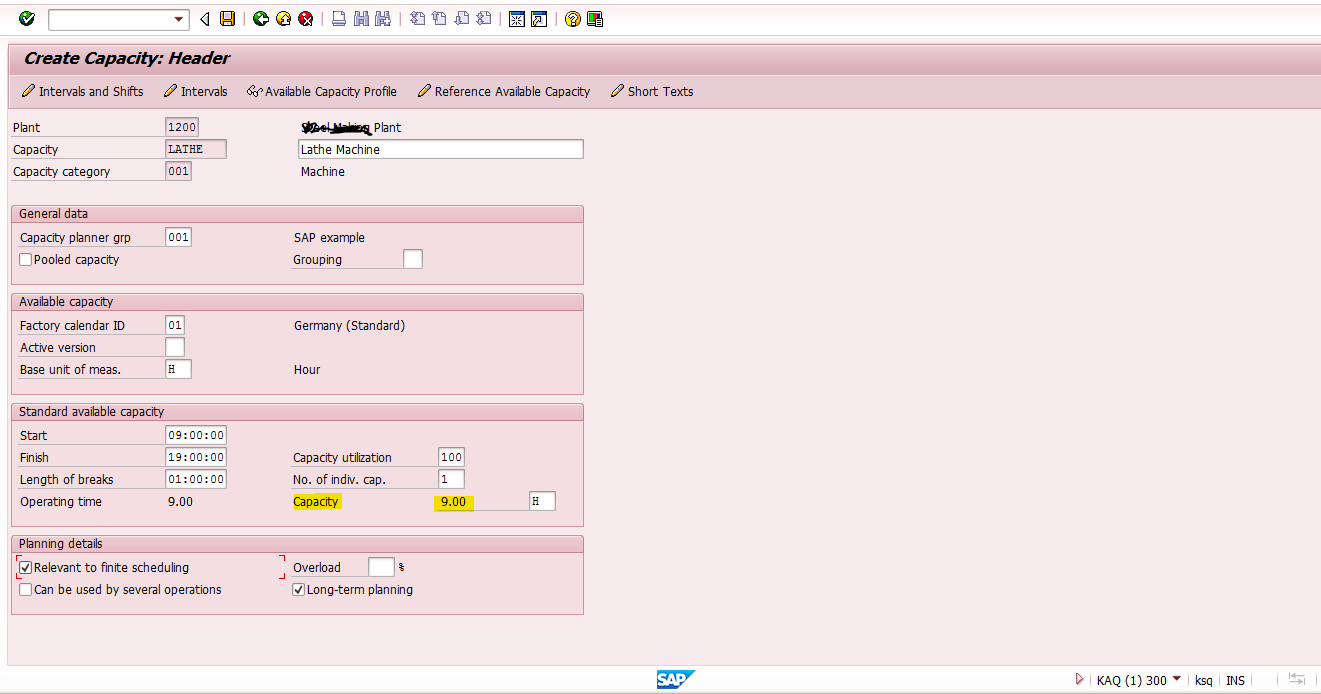

It is also possible to have several similar machines to increase the capacity. SAP has a field called “Number of Individual Capacity”. This is number of individual machines available with similar capacity. When the SAP system calculates required capacity, it divides the amount to the number of individual capacities in formula. When the SAP system calculates available capacity it multiplies the amount to the number of individual capacities.

Capacity formula defined for the machine with 2 individual capacities is as follows:

Machine time * Quantity to be produced / Base quantity / No of splits

Required capacity = (90 mins * 300 PCs / 120 PCs) / 2

Required capacity = 112.5 mins

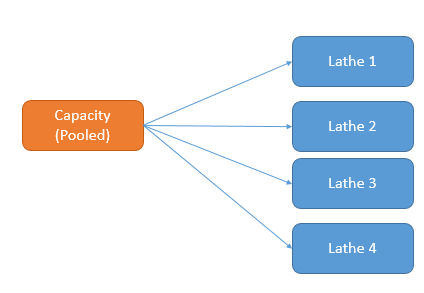

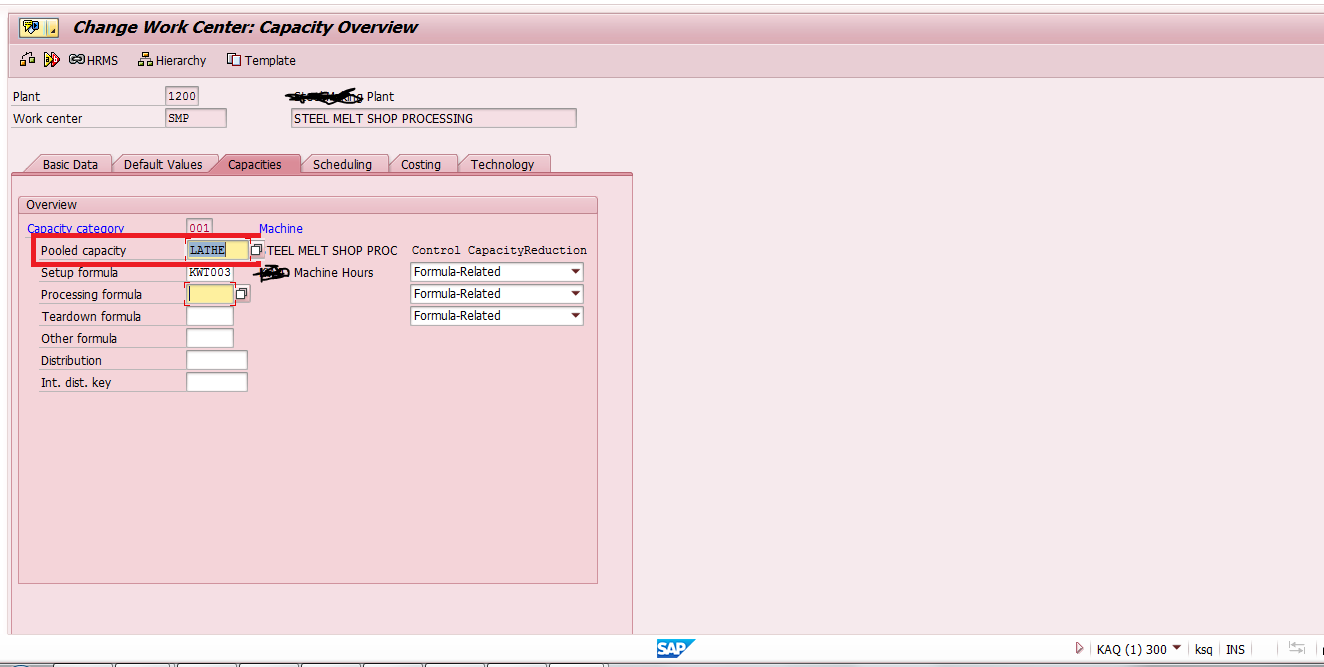

Pooled Capacity

Work centers which are having same capacity type can be assigned with a pooled capacity. This capacity is defined globally and assigned to the all work centers. For example, let say you have 7 lathe machines with similar capacity.

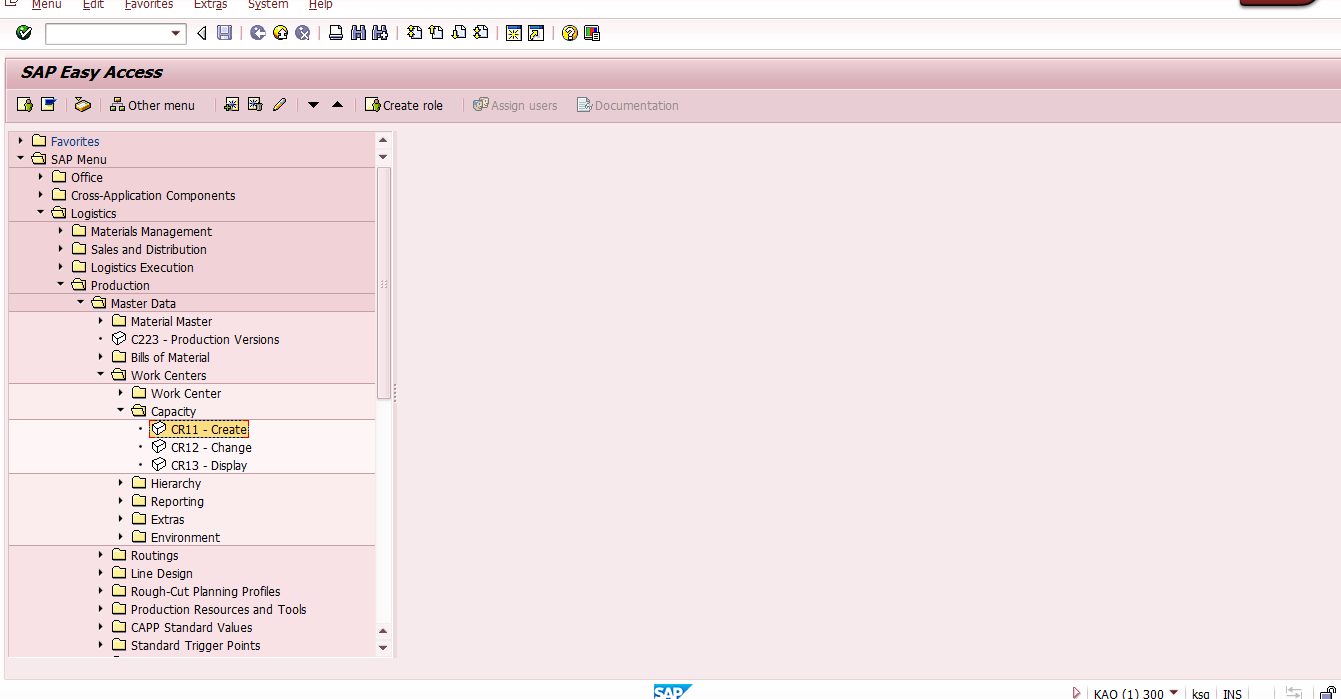

Creation of Pooled Capacity

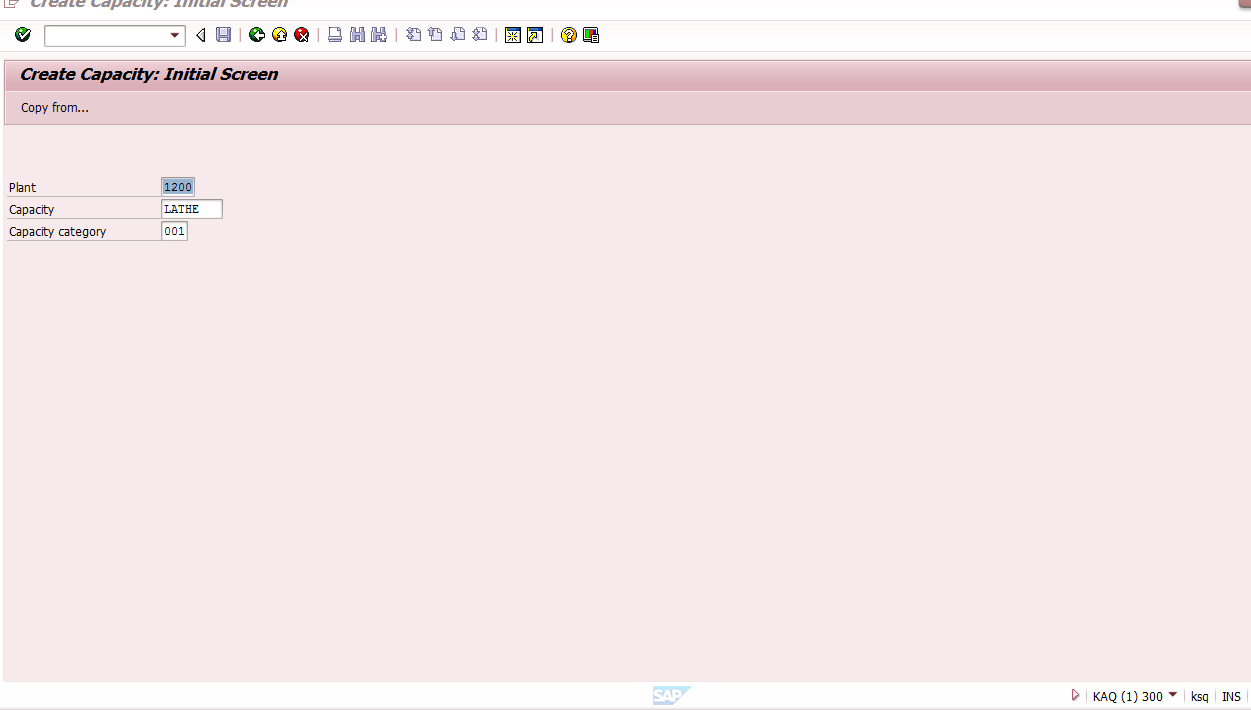

Pooled capacity can be created by accessing following menu path.

Assignment of Pooled Capacity

Once a pooled capacity is created (in transaction CR11), it can be assigned to a work center in transactions CR01/CR02 in Capacity tab.

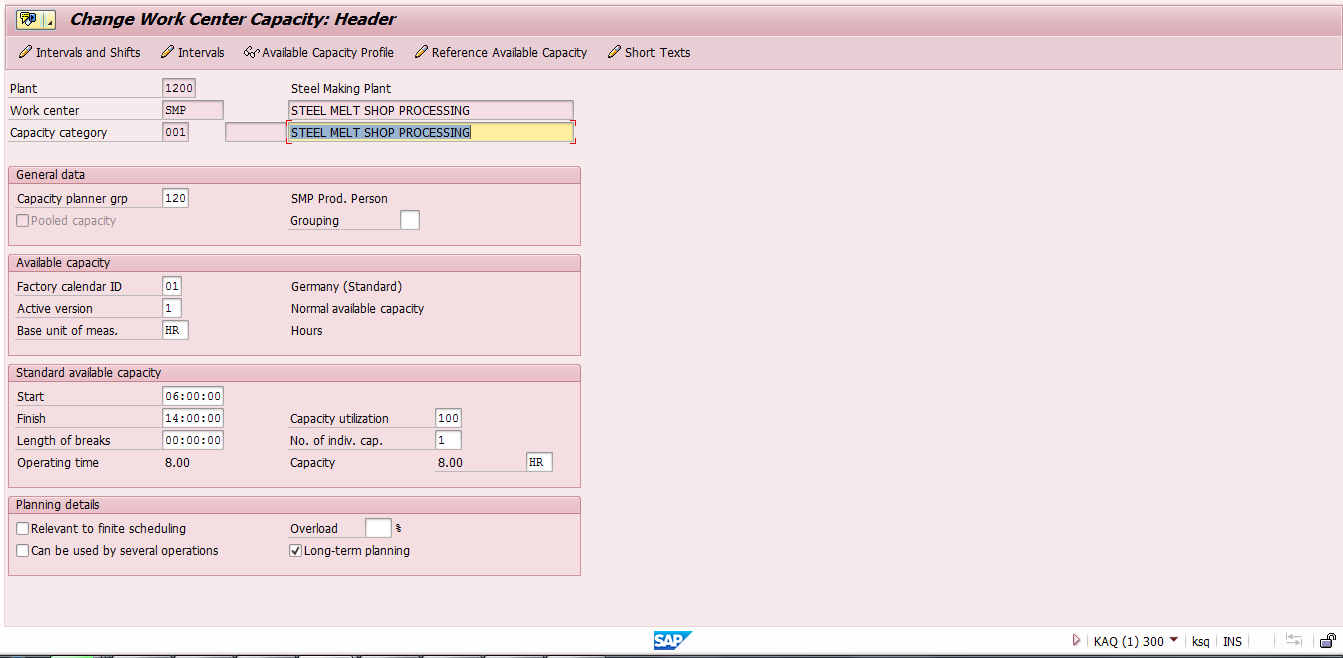

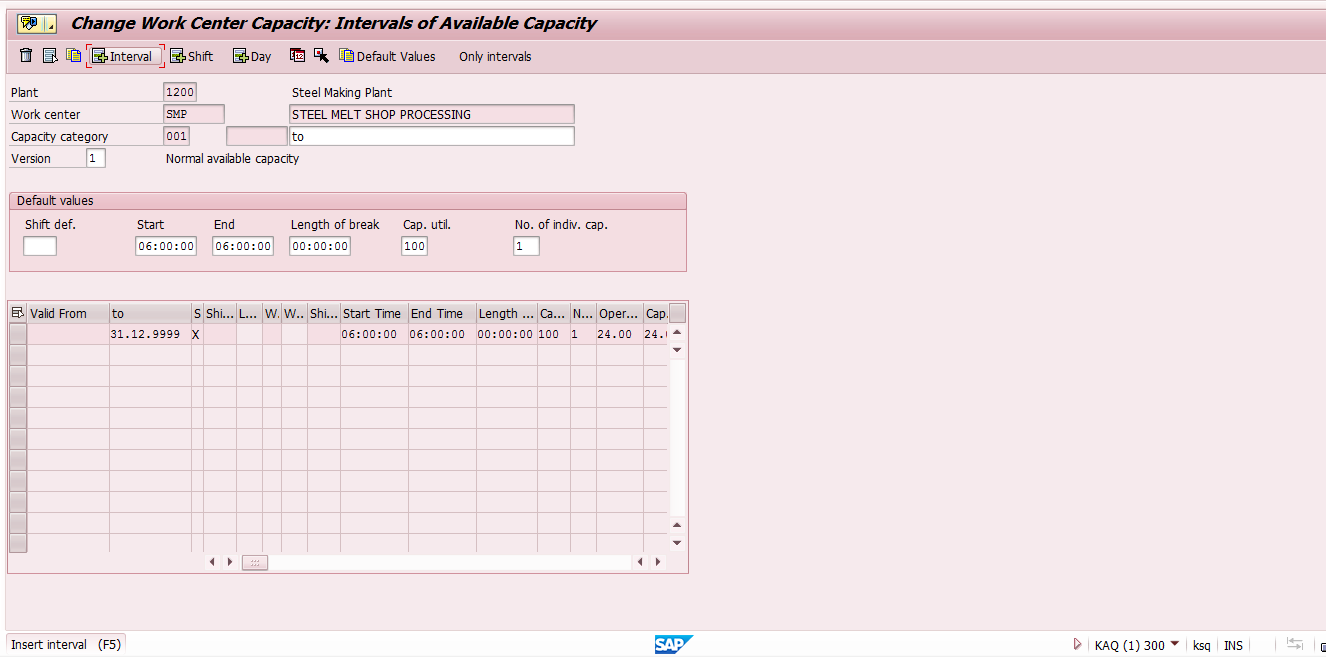

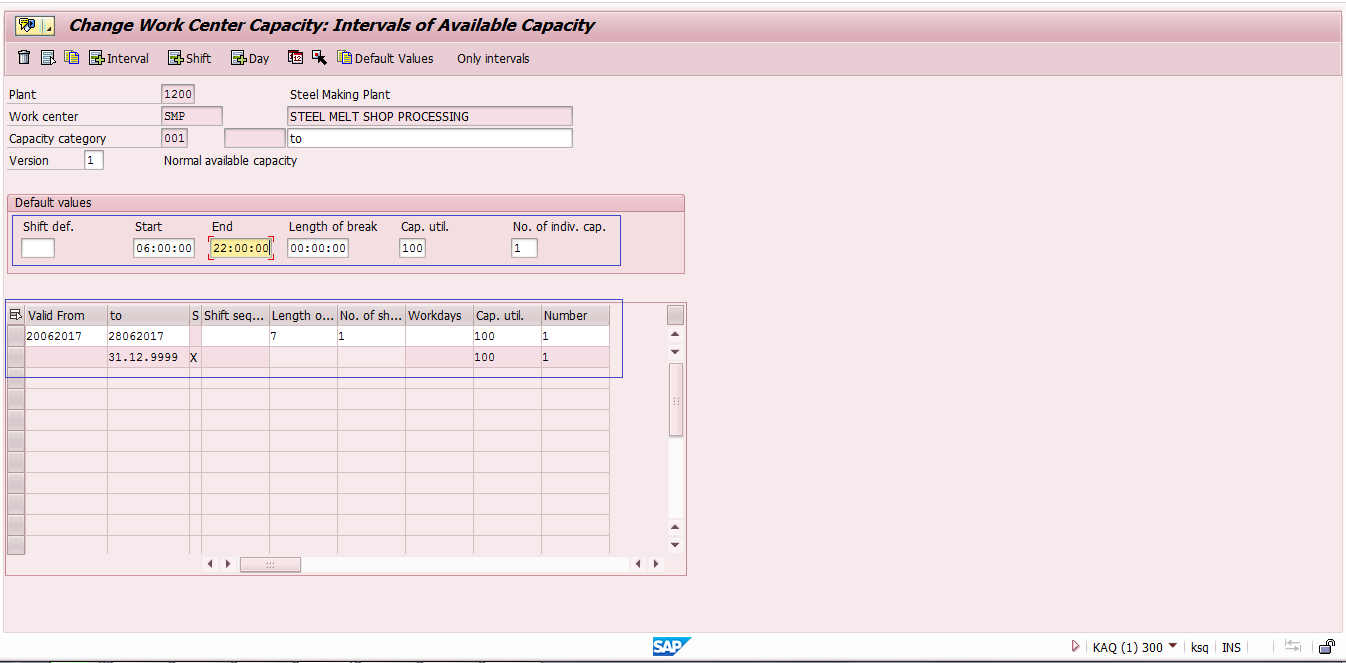

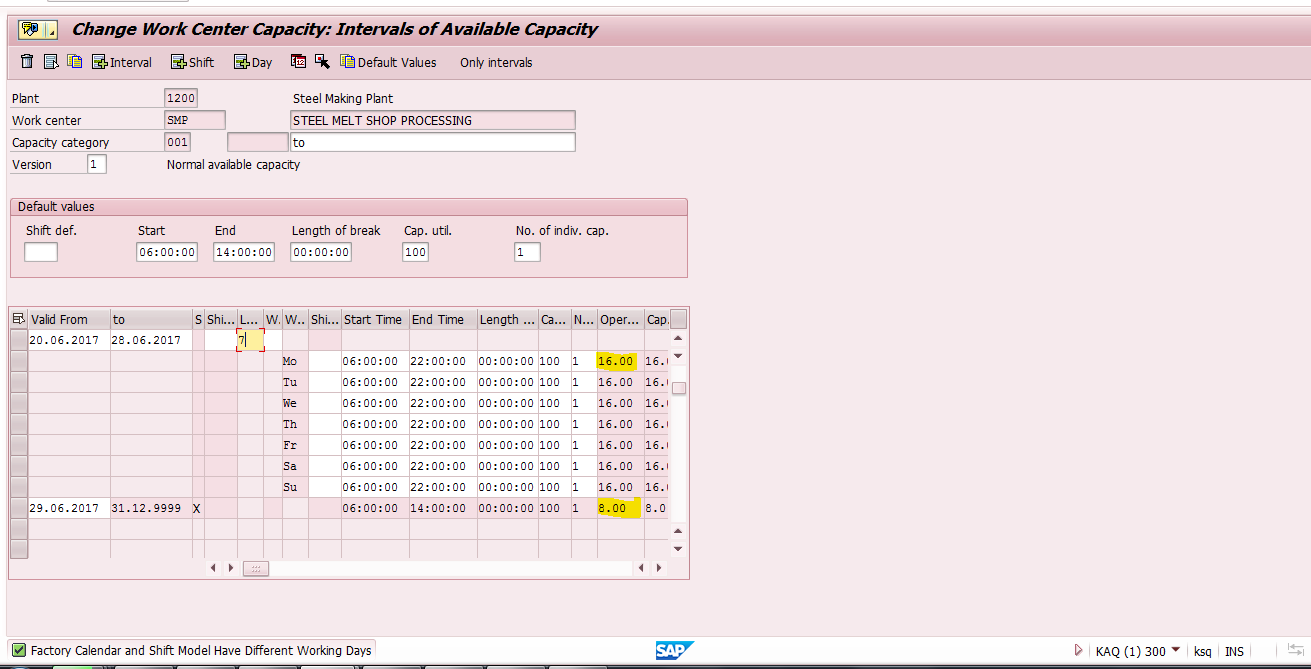

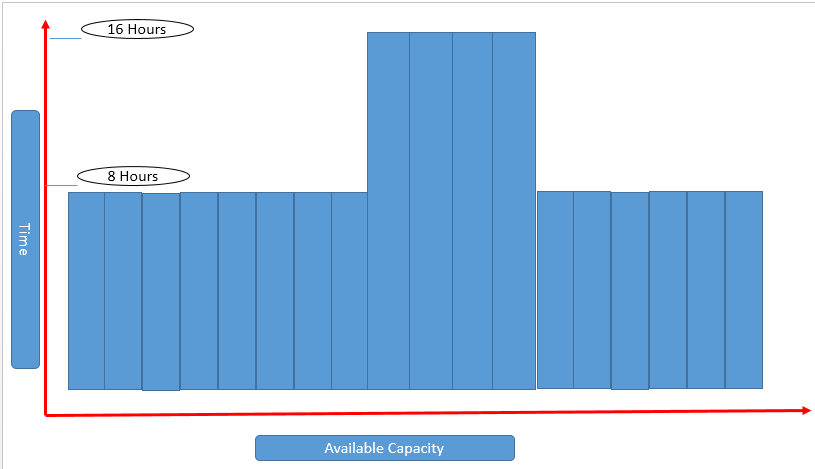

Interval of Available Capacity

When standard available capacity of a machine needs to be replaced for certain periods, we can use interval available capacity. For example, a work center which has the standard available capacity of 8 hours per day but from 20 June to 28 June due to higher demand a company wants to run this machine for 16 hours per day. In this case we can define the interval of capacity for these period as 16 hours.

Create Interval of Available Capacity

To create an interval of available capacity, go to the header part of a capacity (transaction CR11).

Then, click on ![]() button.

button.

Next, click on ![]() button. The system will add a new line for the interval.

button. The system will add a new line for the interval.

Now press Enter button on the keyboard.

Here, you can find that during the period from 20 June to 28 June (interval of capacity) available capacity is 16 hours, whereas for rest of the days it is 8 hours (standard available capacity).

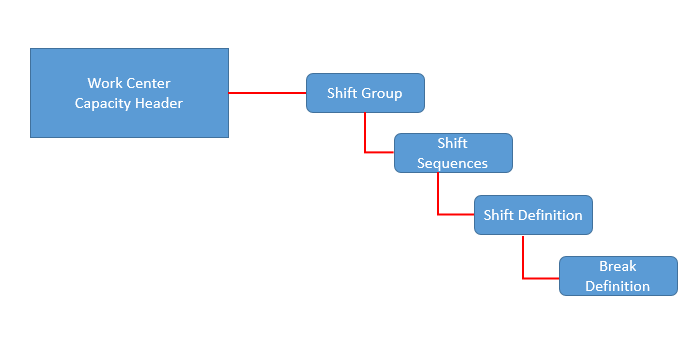

Shift Definitions, Shift Sequences, and Breaks

Capacity and planning calculations can also take into account shifts. Let’s see how to define shifts and breaks in SAP.

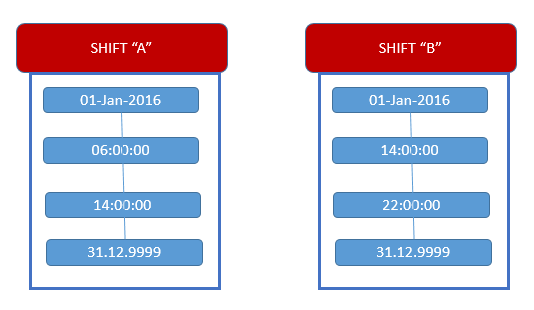

Shift Definition

The following parameters are maintained in definition of a shift:

- Validity period of a shift (start date and end date)

- Start time and end time

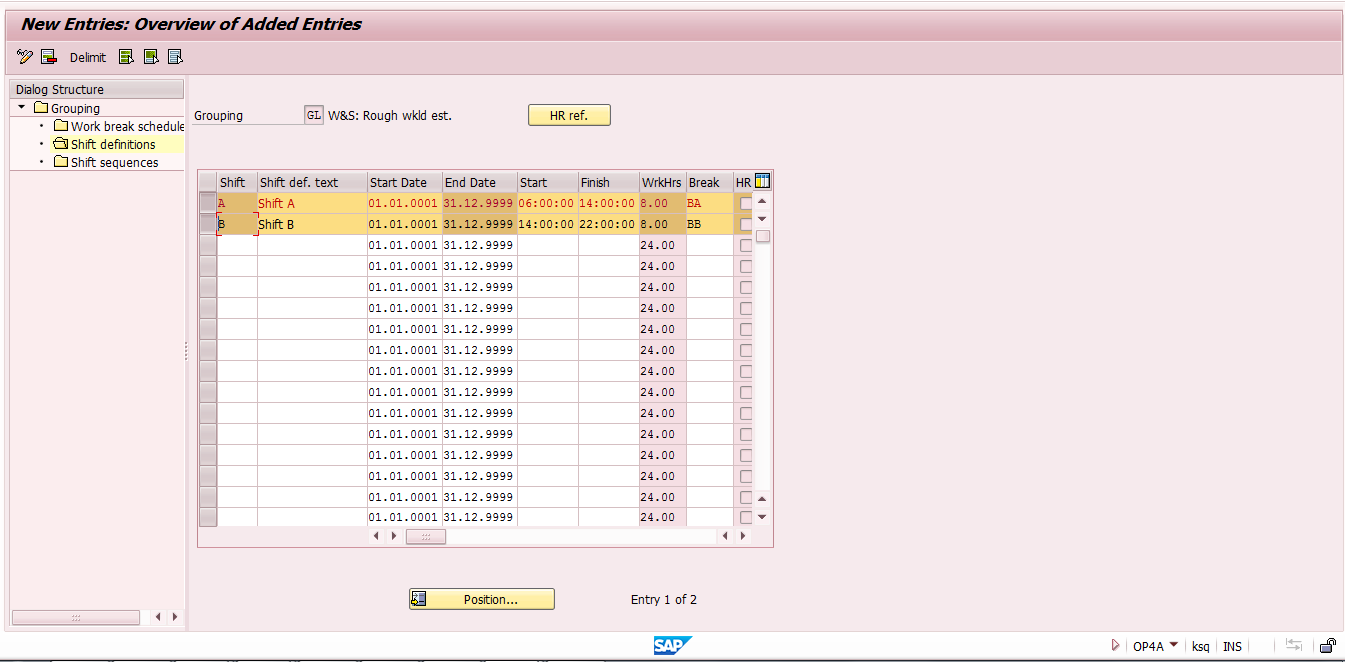

Example

A company operate with 2 shifts:

- “A” Shift —- 06 AM to 14 PM

- “B” Shift —- 14 PM to 22 PM

Shift definition will be maintained as show on the picture below.

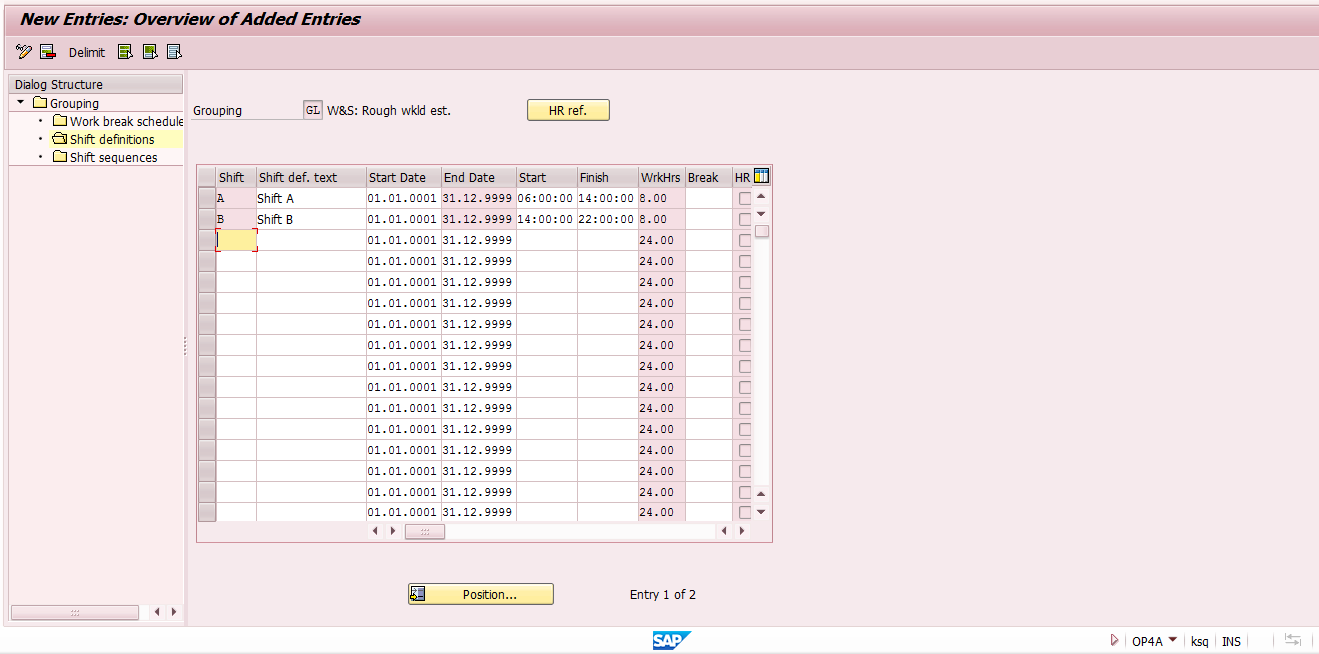

Shift definition in SAP is part of customizing activity which needs to be performed in the transaction OP4A.

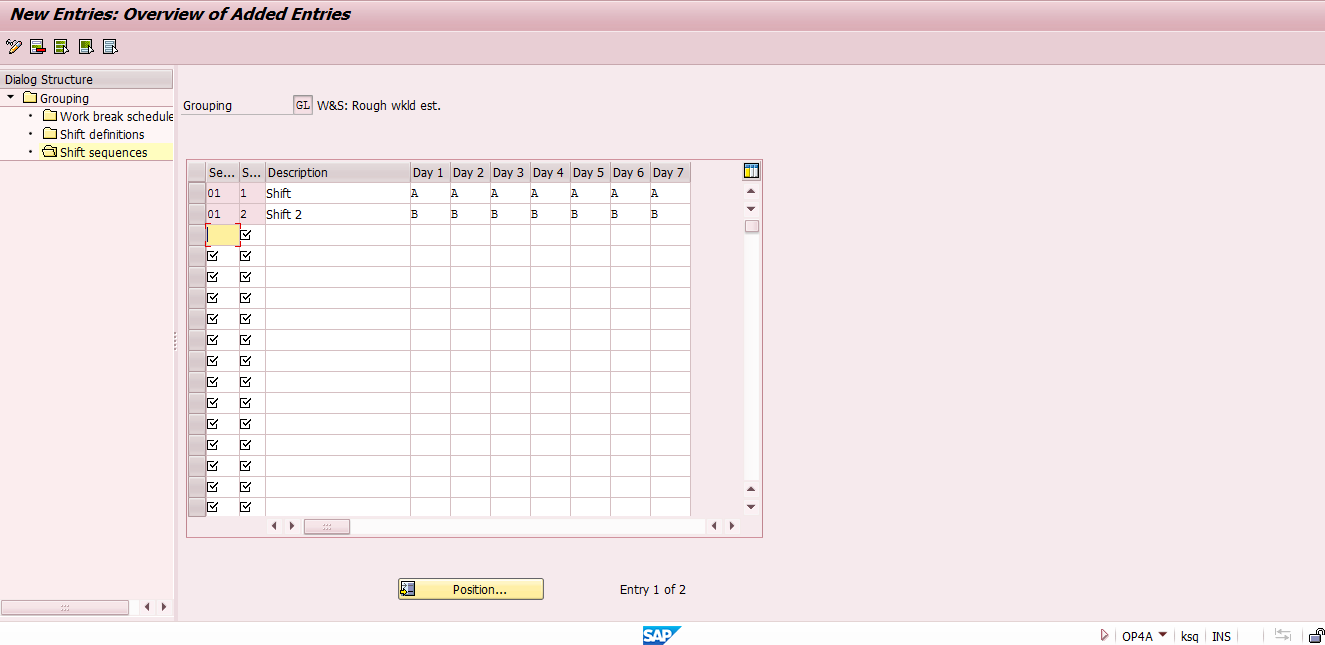

Shift Sequences

Next, we should define the sequence of our two shifts. The sequences of the shifts are defined in the same transaction as shown on the picture below.

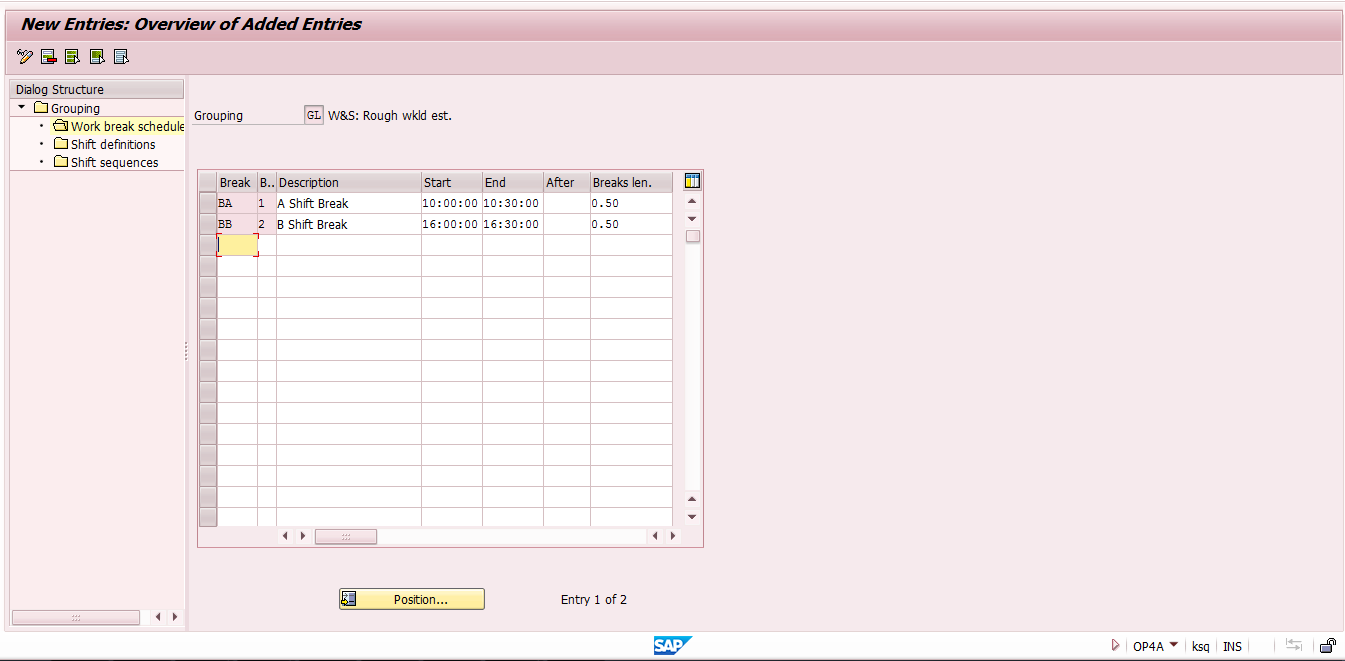

Break definition

Additionally, we can define break times for each shift and assign them in shift definition later.

Use of Shift Sequences in Work Center

Shift timings and breaks will be used at the time of capacity and scheduling calculations. By default, the SAP system schedules the break time to be distributed equally over the working hours. When we want the system to uses exact break times defined in the shift the indicator “Scheduling with Break” needs to be maintained in the production order type.

Note: this topic will be discussed in more details in the tutorial about production orders.

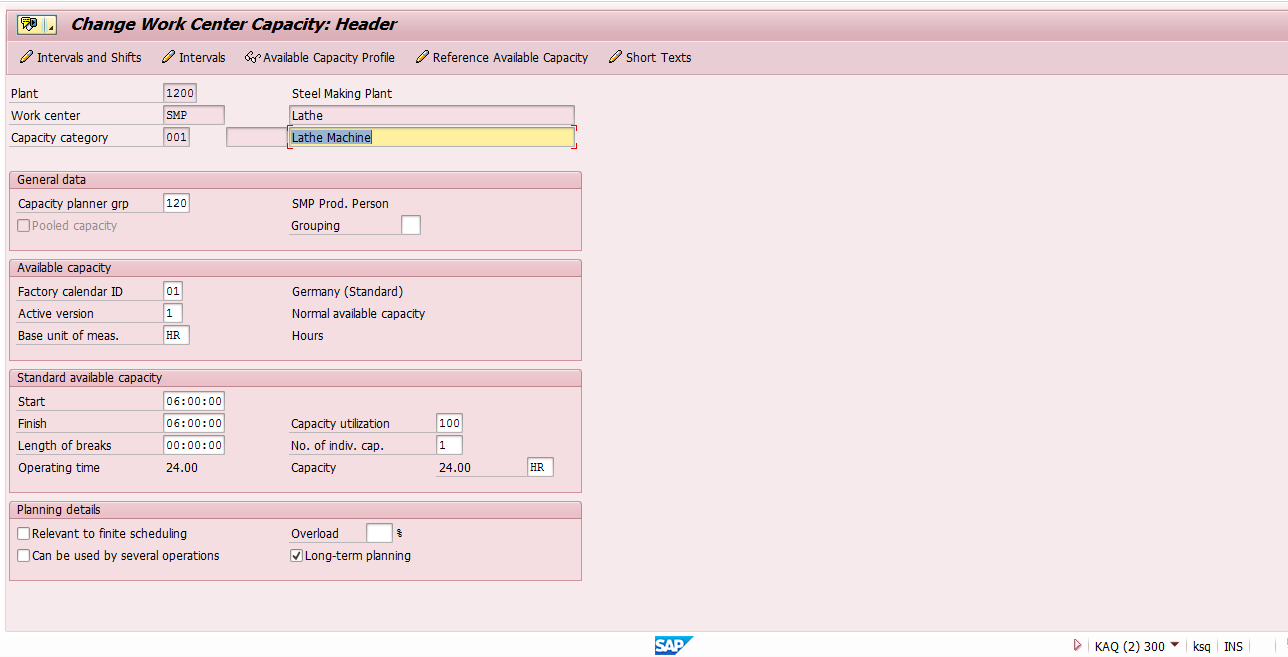

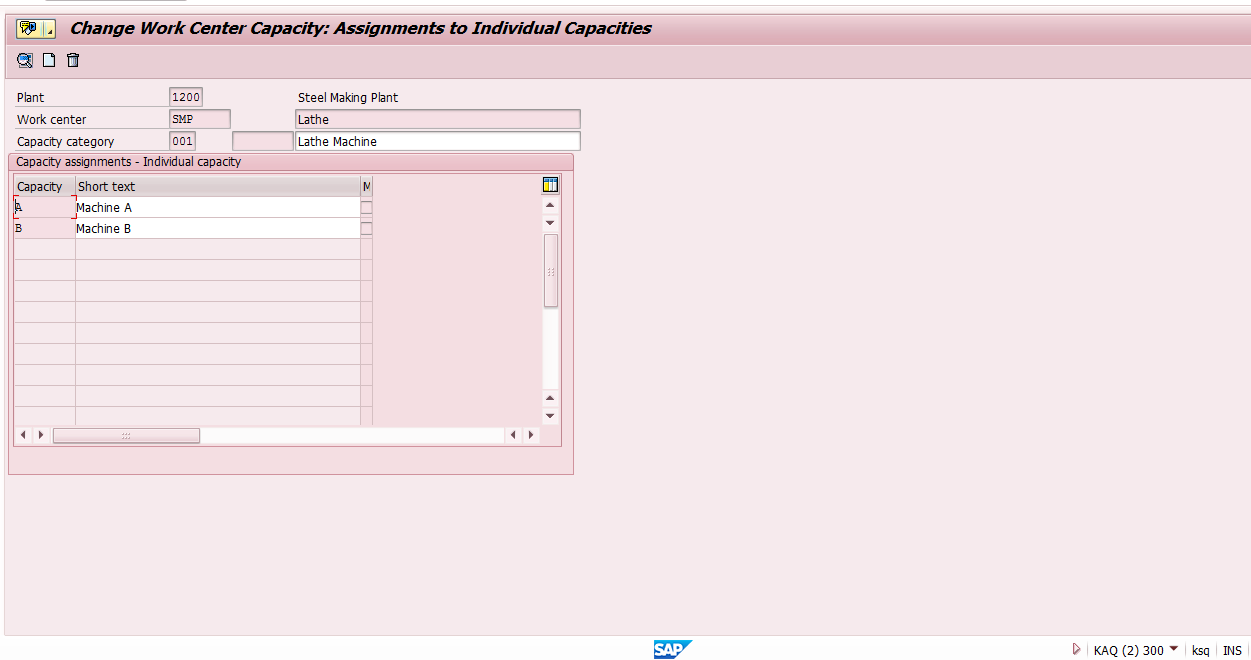

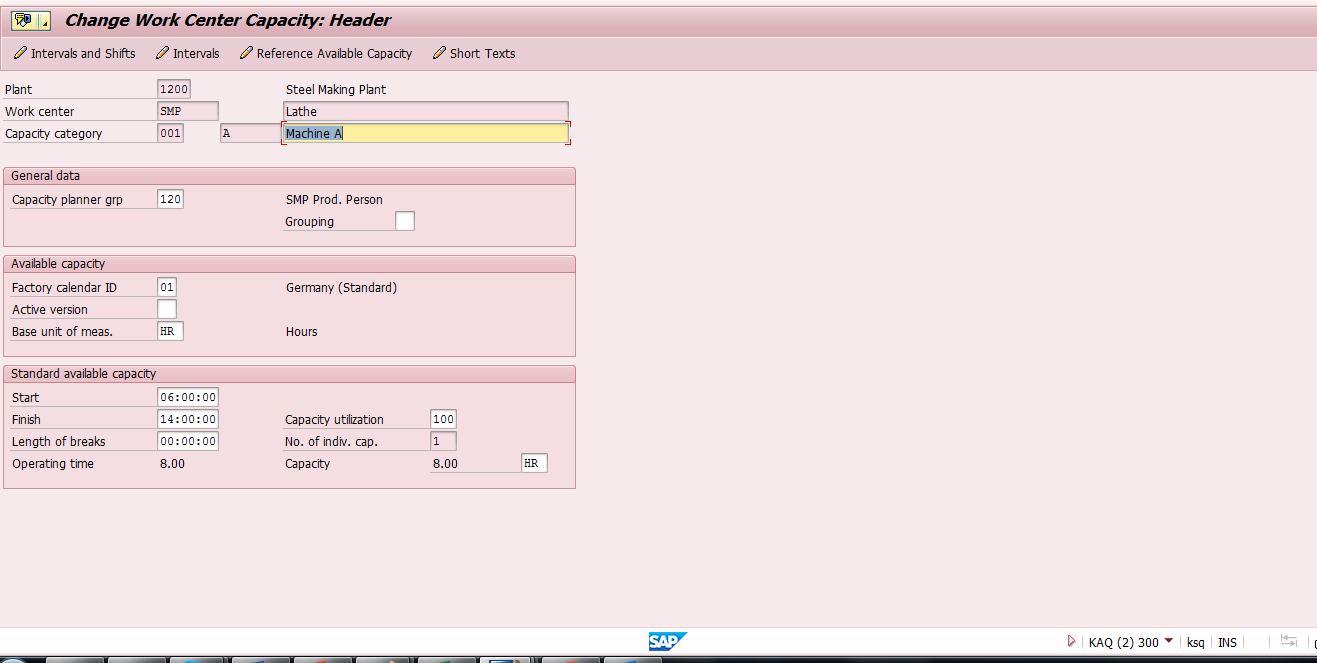

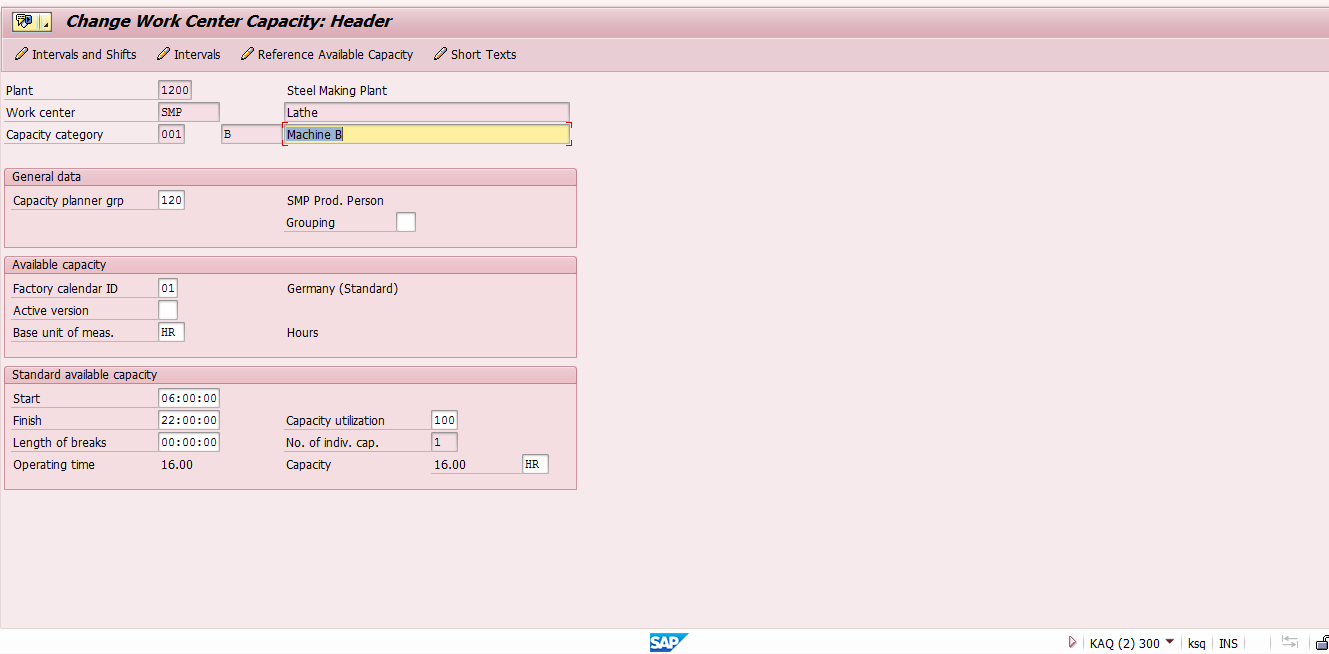

Individual Capacity

Individual capacity in SAP is used for detailed capacity requirement planning. This can be explained with the following example:

- Let’s say you have Lathe machines A and B

- Machine A is available from 06:00:00 to 17:00:00 hours

- Whereas Machine B is available from 06:00:00 to 22:00:00 hours

- A possible way of mapping in SAP for this scenario is:

- Create two work centers with different capacities

- Create only one work center but two individual capacities need to be created inside the work center capacity

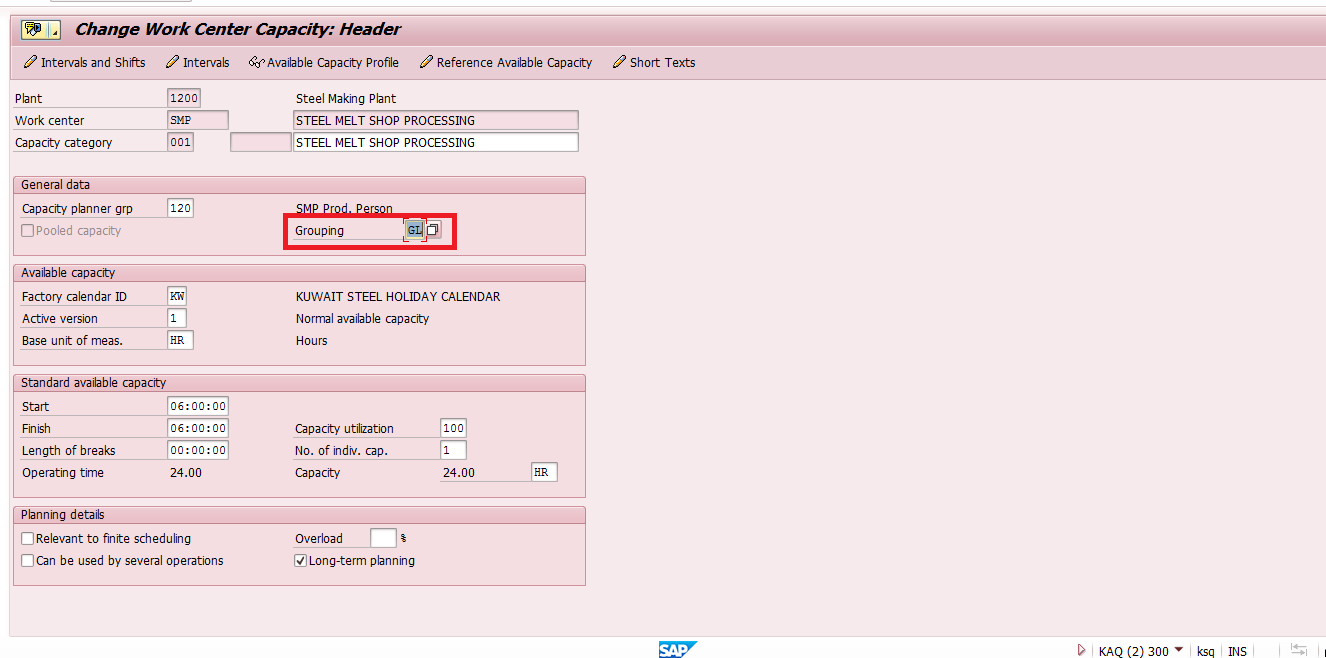

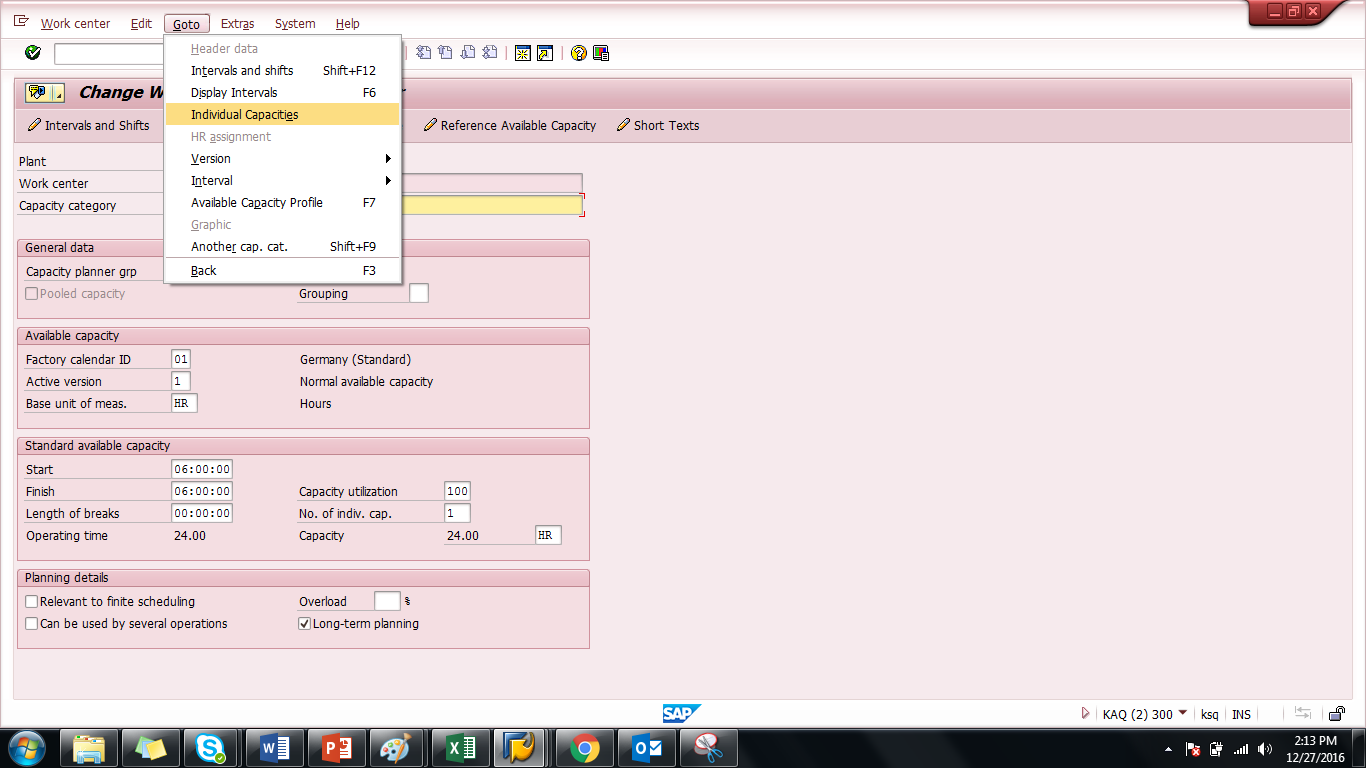

To see how it works in SAP, go to the transaction CR11.

Select each item in the list and click on ![]() button. The SAP system will show individual capacities for machines A and B.

button. The SAP system will show individual capacities for machines A and B.

When creating a production order it will be necessary to assign the individual capacity that we are going to use to perform the operation.

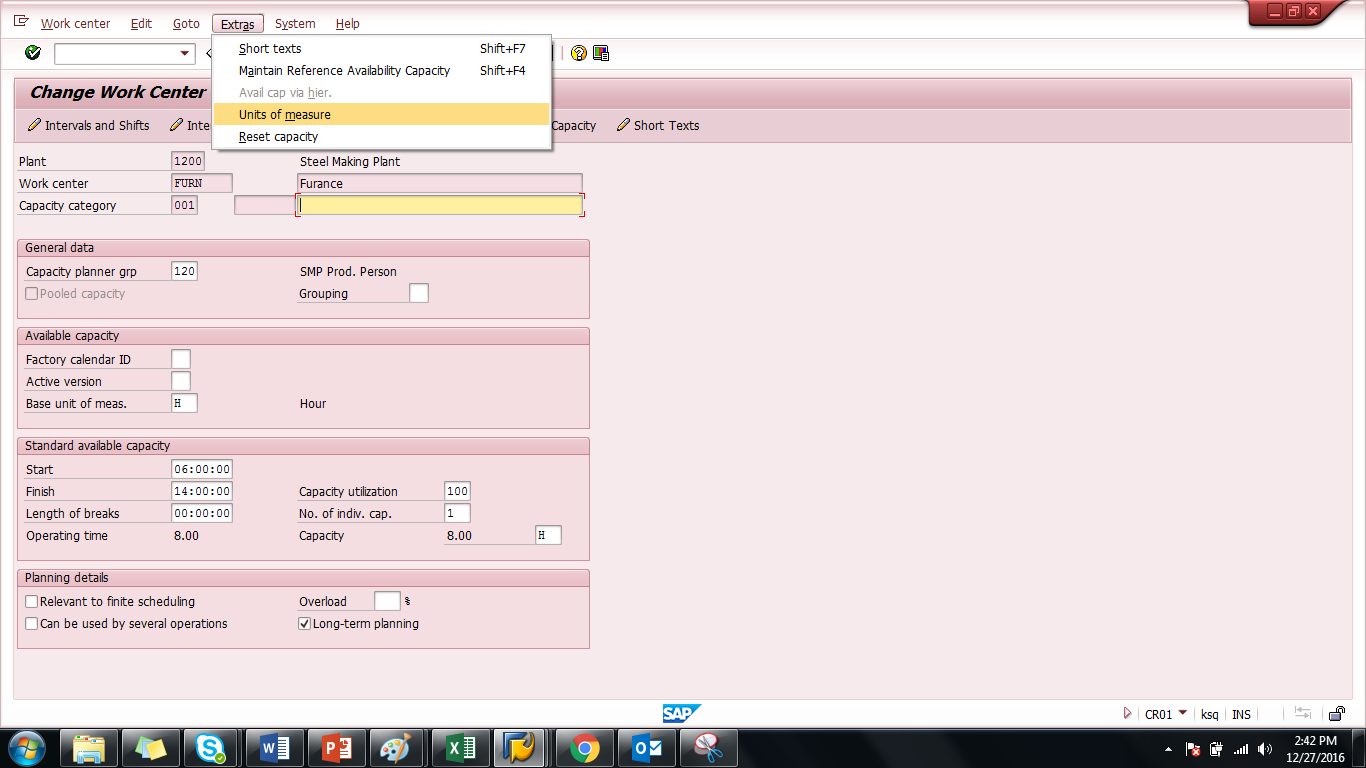

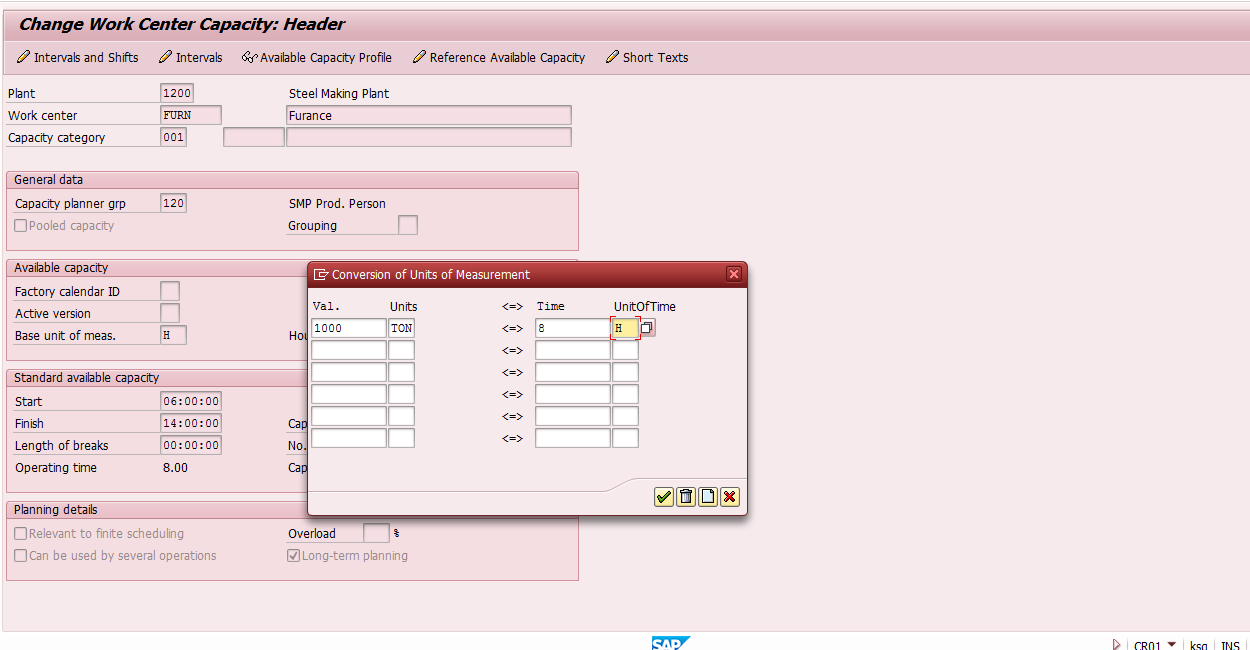

Capacity in Different Unit of Measure

In general, capacity is defined in the unit “Hour”. But there may be a case when a different unit of measure (UOM) can also be maintained. UOM may be Cubic Meter (M3) or KG or TON, etc.

For an example, let’s consider the casting industry where casting is formed from molten metal from furnace. Here furnace capacity can also be defined in “TON”. But the relation between TONs and Hours must be maintained in the work center capacity. This will be used to evaluate the capacity in TONs.

Capacity and Work Center Hierarchy

Capacity can be cumulated by means of work center hierarchy. Hierarchy of work center enables cumulation of available capacities from child work centers to their superior work center.

There are two types of cumulation available in SAP:

- Dynamic Cumulation

- Static Cumulation

Dynamic cumulation is used to cumulate both available capacity and required capacity, whereas static cumulation cumulates available capacity of a hierarchy of work centers.

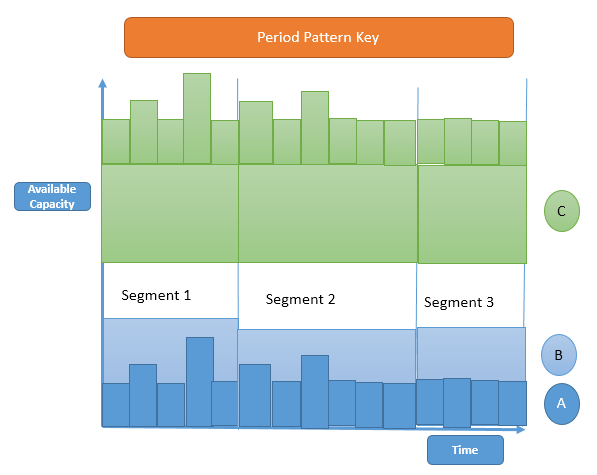

Static Cumulation and Period Pattern Key

In static cumulation, available capacity cumulation is calculated using Period pattern key. Period pattern key is used for:

- Cumulating available capacity

- Displaying available capacity

In static cumulation, cumulated available capacity of a superior node will not be changed automatically when there is a change in the available capacity of a subordinate work center. So, we must cumulate available capacity periodically.

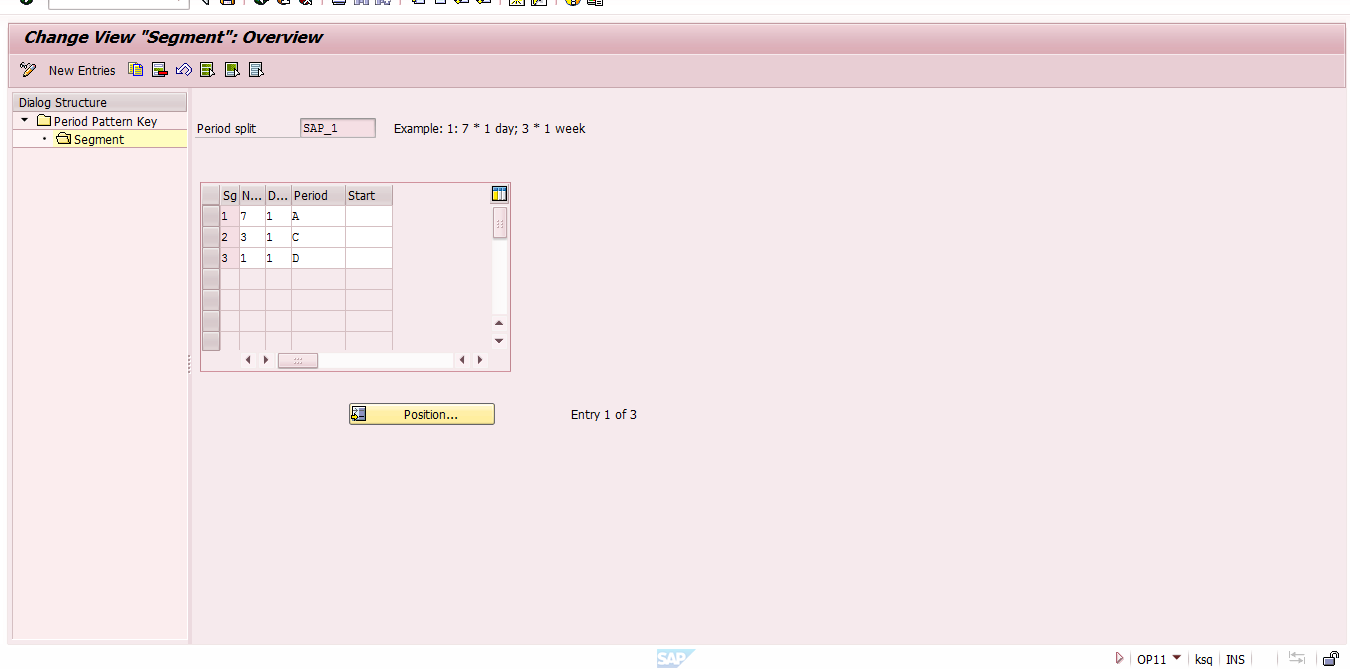

Definition of Period pattern key is part of customizing activity using transaction OP11.

Example

Let’s image that you want to cumulate available capacity as three segments on the time axis. The first segment, cumulate next 7 days of available capacity. The second segment, cumulate next 3 weeks from last period of the segment 1. The third segment, cumulate 1 month of available capacity from the last period of the segment 2.

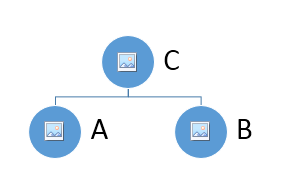

Work center Hierarchy for the above diagram is as shown on the picture below.

Here, available capacity of work center A and B are cumulated in a higher hierarchy. That is, cumulated available capacity is displayed in available capacity of the work center C.

Creation of a period pattern key is part of customizing activity in the transaction OP11. Periods in a period pattern key may be work days, calendar days, weeks, months or years.

Let’s say that available capacity of SAP work center A is 12 Hours and work center B is 18 hours. Then, available capacity of work center C will be calculated as 30 hours. If period pattern key is defined as a week, then available capacity for a week will be cumulated.

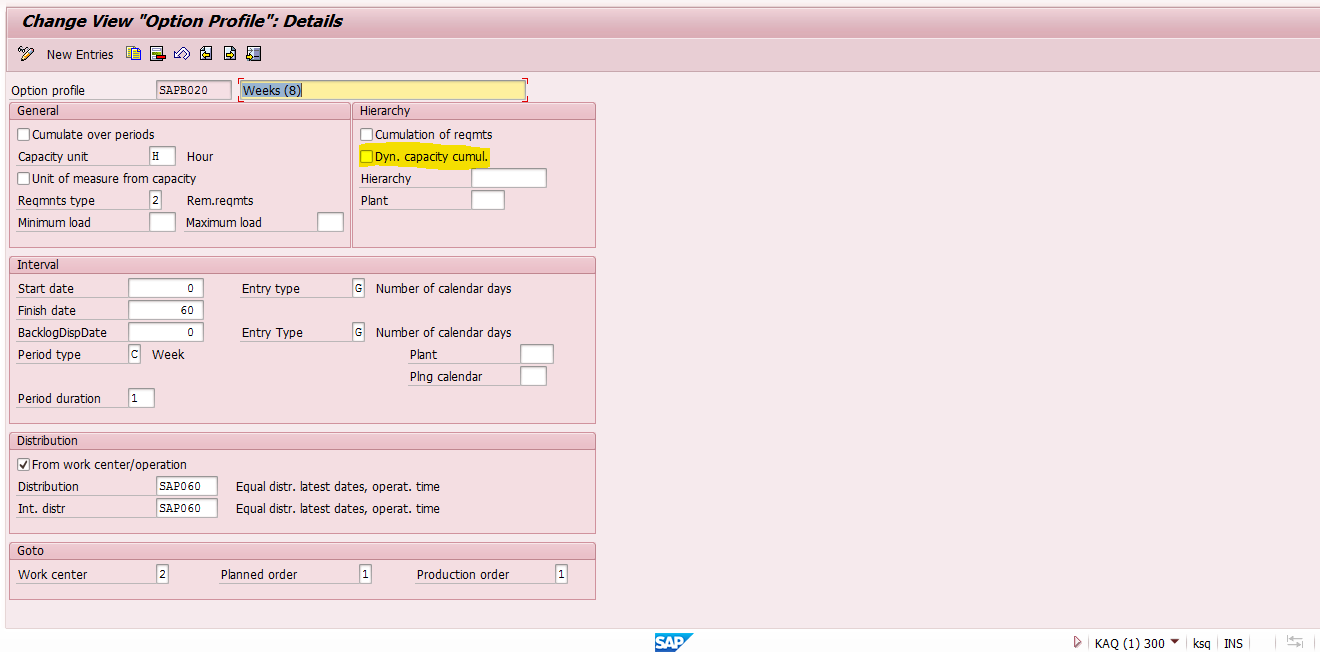

Dynamic Cumulation

In dynamic cumulation, the SAP system cumulates the available capacities and the capacity requirements for all capacity categories of the work centers specified in a hierarchy.

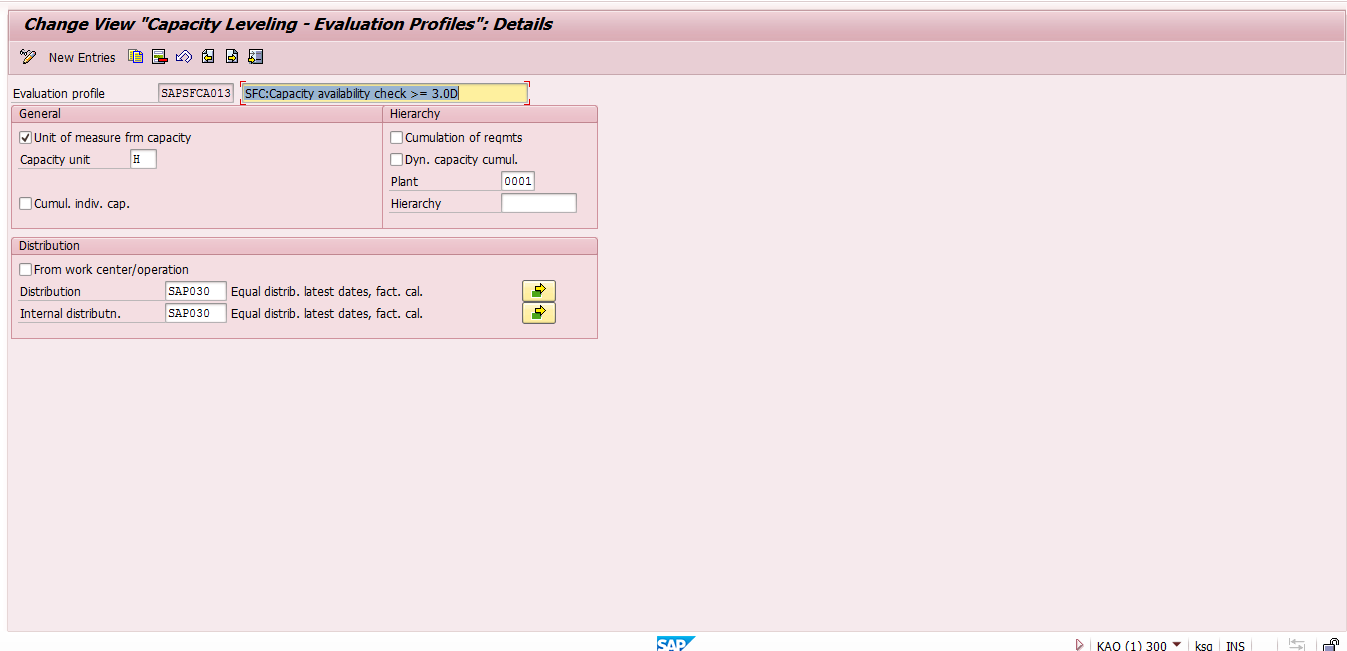

This is defined in Option Profile which is part of customizing activity for the case of available capacity cumulation (transaction OPA3).

This is defined in Evaluation Profile which is part of customizing activity for the case of required capacity cumulation (transaction OPD0).

Example

Let’s consider the same example given for the static cumulation. When Lathe machines are loaded with capacity by order (say 4 hours each), dynamic capacity cumulation cumulates this required capacity (4 hours + 4 hours) into the work center hierarchy C as 8 hours.

This will be discussed in more details in capacity requirement planning tutorial.

Indicators Influencing Capacity Planning

Finally, let’s discuss several important checkboxes in SAP work center capacity master data (transaction CR11).

Relevant to finite scheduling indicator

When this Indicator is activated the SAP system considers the existing capacity load while calculating available capacity.

Let’s say Machine ‘A’ which has available capacity of 8 hours was scheduled for an order on 10 July for 4 hours 30 mins. When a new order is created for this machine on same date, the system will propose only remaining hours (3 hours 30 mins).

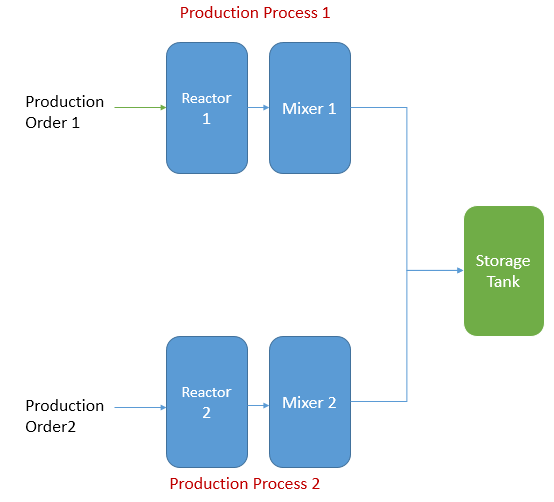

Can be used by several operations indicator

When this Indicator is activated, that particular work center capacity can be utilized by more than one operation. This allows the SAP system to consume the available capacity for other production orders.

For example, let’s say you defined a storage tank as a work center in the chemical industry. When two production orders try to use this storage tank to fill the finished chemical, the SAP system will only allow this when this indicator is activated.

Long term planning

When this Indicator is activated, this work center capacity can also be used to calculate capacity requirement of long term planning.

Note: long term planning in SAP is also called simulation MRP where we can upload demand simulation to calculate required raw materials and capacity for an assembly/subassembly.

—

Did you like this tutorial? Have any questions or comments? We would love to hear your feedback in the comments section below. It’d be a big help for us, and hopefully it’s something we can address for you in improvement of our free SAP PP tutorials.

Navigation Links

Go to next lesson: SAP Work Center and Cost Center Integration

Go to previous lesson: SAP Work Centers

Go to overview of the course: SAP PP Training

IT WOULD BE SUPERB IF THE TUTORIAL IS PRINTABLE …….

VIDEO VERSION WILL DEFINITELY ACCELERATE LEARNING….

This is a very good tutorial, comprehensive and with good examples.

very nice explanation of topic covered

very good ..

Very nice and detailed document. Thanks for sharing.

Great tutorial, I love ERProof as you always keep the topics simple yet very helpful!

Keep up the good work!

Regards

Filip

Very good explanation with understandable examples! Thank you for sharing it.

Table name required

Really super

Thanks a lot very helpfull and clear examples !!

Would be great have more information to the same capacity topic:

* how is the definition when not only time, but other capacity limitations must considered during planning (for example with PPDS) -

[ Error rise at definition: Capacities of type 1 or 2 are only allowed for resources

Message no. CR343 ] no SAP help or hint for that

- other than basic workcenter, for example production line (takt based) : how is the right definition?

Thank you Velmurugan Saravanavelu,

Well described information with screenshots.

I am trying to find the answer on Work Center Capacity Allocation No. (CRCA-CANUM). What I noticed that when Capacity information is saved in work center a Capacity Allocation Number in Table CRCA is created (Usually it is 512) but also noticed different number as well!

Do you know anything on this as to how this number is allocated to work center?

Thanks

Rakesh