Warehouse order is an essential document in SAP Extended Warehouse Management (SAP EWM). The main idea behind SAP EWM Warehouse Order is that it eases and optimizes the categorization of the work to be done. In this tutorial, we will start with introducing the concept of a warehouse order in SAP EWM. Then, you will learn about the best practice SAP EWM warehouse order processes. Finally, we will explain the purpose of warehouse tasks and how they are related to warehouse orders.

SAP EWM Warehouse Order

In EWM, the warehouse order is the document that represents an executable work package that a warehouse employee should complete within a given time. The warehouse order, consisting of one or more warehouse tasks, is then assigned to a resource (as per EWM resource management set up) for the execution of goods movement. After the worker completes the assigned tasks in each warehouse order, the warehouse order is confirmed. Upon confirmation, the goods movement takes place within the warehouse in which products are moved from source to destination bin.

SAP EWM Warehouse Order Process (Inbound and Outbound)

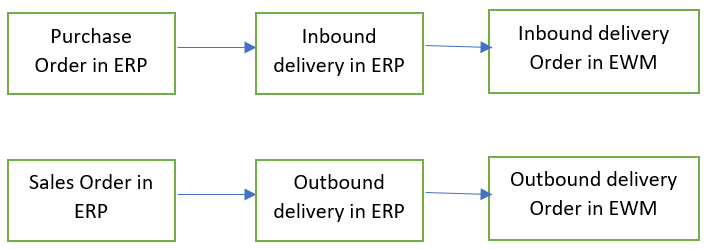

The process starts in ERP. For the process of inbound, the ERP inbound delivery is distributed into the EWM and creates Inbound Delivery in the EWM S/4 HANA system. The EWM inbound delivery is also known as ‘warehouse request’ where the delivery data from ERP is mapped, EWM-specific data is determined, and a Warehouse Process Type is assigned. The Warehouse Process Type controls the processing of a warehouse task in EWM. Similarly, for the outbound process, the ERP outbound delivery is distributed into the EWM. It will create the outbound delivery order, which is the warehouse request for the processing of the goods to be issued.

Warehouse request provides the worklist for EWM and is the basis for the execution of picking/stock removal or putaway activities. The warehouse request creates warehouse tasks. Warehouse tasks execute proper movements in the warehouse. For example, it will tell the operator to move the stock/pallet of a product from one location to another, as shown in the figure below.

Warehouse Tasks

These tasks are needed for the following warehouse activities:

- Internal movements

- Picking

- Putaway

- Posting goods issued

- Posting changes

- Posting goods receipts

When a warehouse task is executed, it must be confirmed. During the confirmation stage, the warehouse personnel confirms that the correct quantity of the product arrived at the destination bin. The warehouse tasks are bundled in the Warehouse Order as shown in the figure below for both inbound and outbound movements.

Did you like this tutorial? Have any questions or comments? We would love to hear your feedback in the comments section below. It’d be a big help for us, and hopefully, it’s something we can address for you in the improvement of our free SAP EWM tutorials.

Navigation Links

Go to next lesson: SAP EWM Warehouse Order Creation Rules (WOCR)

Go to previous lesson:

Go to overview of the course: SAP EWM Training

Very clear and helpful, thanks

Good