This module of our free SAP PM training course is about SAP PM work center. After completing the module about work centers in SAP Plant Maintenance (PM), you will know what are work centers in SAP and what is their functions in SAP PM module. Also, you will learn how to create, edit, and view work centers. As usual, don’t forget to check out the video accompanying this SAP PM tutorial.

This module of our free SAP PM training course is about SAP PM work center. After completing the module about work centers in SAP Plant Maintenance (PM), you will know what are work centers in SAP and what is their functions in SAP PM module. Also, you will learn how to create, edit, and view work centers. As usual, don’t forget to check out the video accompanying this SAP PM tutorial.

What is SAP Work Center?

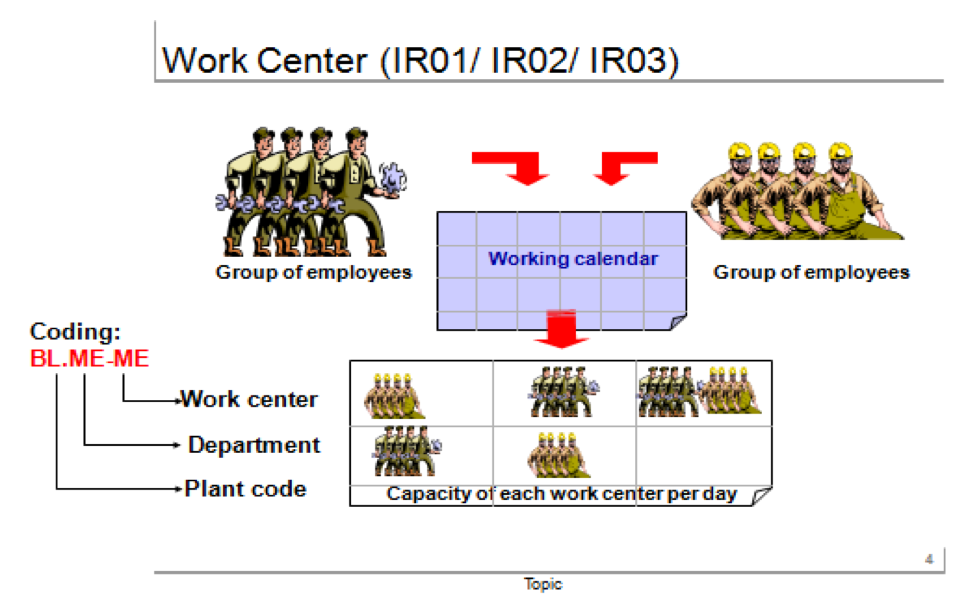

SAP PM work center are nothing but groups of people or technicians or experts those who physically carry out the maintenance activity in Plant Maintenance department on different areas like mechanical, electrical, instrumentation etc. The following figure illustrates the work centers. The coding is mentioned here in only for reference and this can be in any format as per the business or project need.

The transaction codes for working with work centers are:

- Center work center: IR01

- Edit work center: IR02

- Display work center: IR03

As we explained earlier, personnel with different skill set in factories or manufacturing units will do various types of activities such as mechanical, electrical or PLC (programmable logic controllers), and so on as per the work need. Each of these types of activities are created in SAP as different work centers and these work centers will be used in plant maintenance orders as per the need while carrying out maintenance operations.

Create SAP Work Center

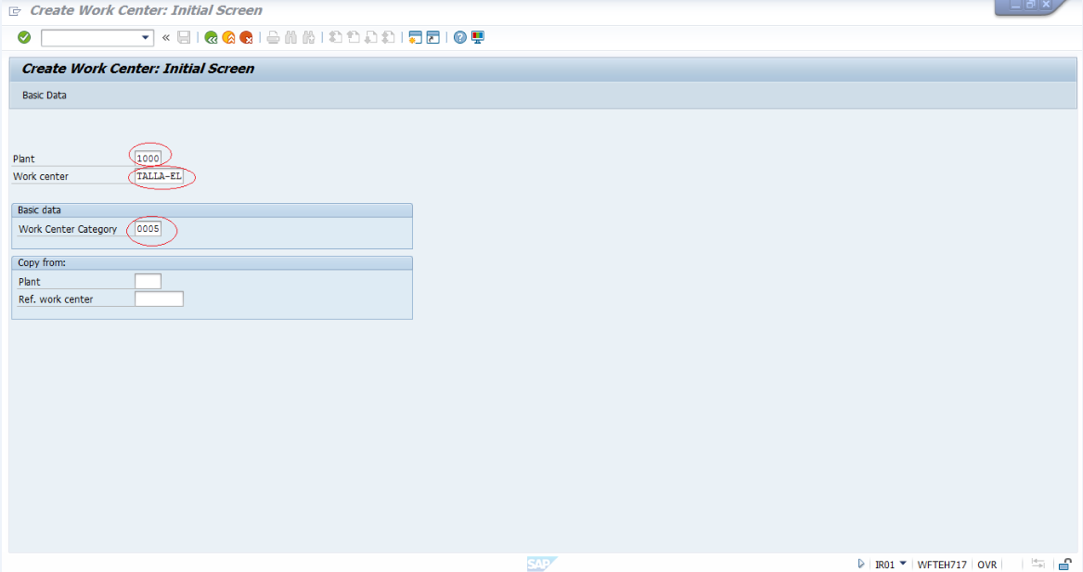

Let us create a maintenance work center now. The transaction code for creating a work center is IR01.

In the header part of the screen, we enter:

- the plant code (1000 in this case);

- work center name (something that will help to identify this work center later);

- the work center category as 0005.

The standard work center category for plant maintenance is 0005. Once we hit enter it will take us to the next screen with the Basic Data tab as shown below.

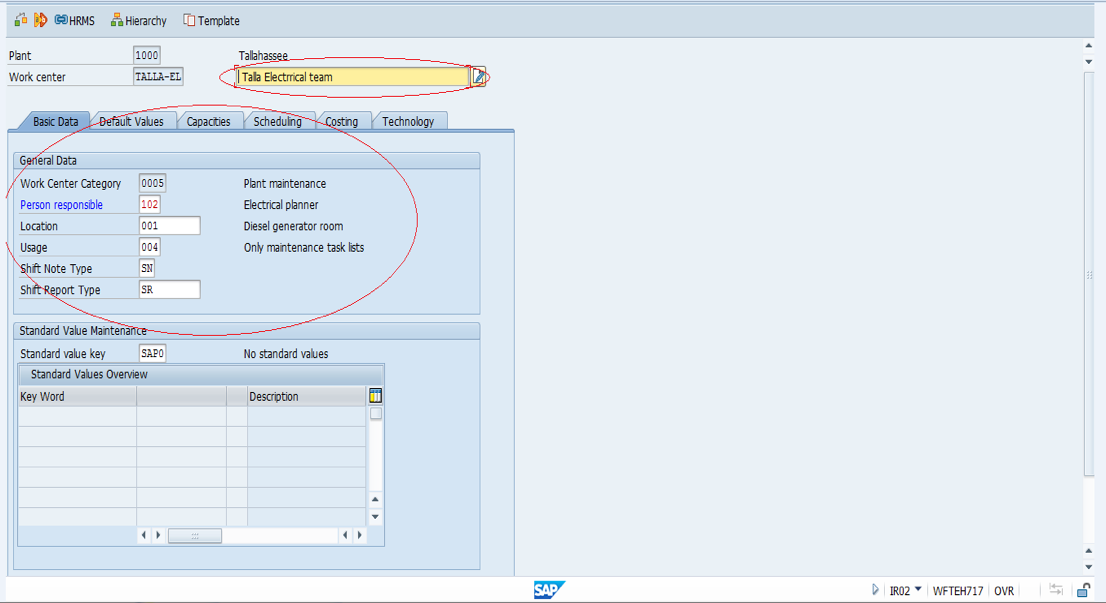

Here we should enter all the relevant data as demonstrated in the above screenshot. At the top of the screen we first need to enter the work center description. The work center category is default to 0005 and the usage is 004 which is a standard for the maintenance task list where remaining data can be selected from a dropdown.

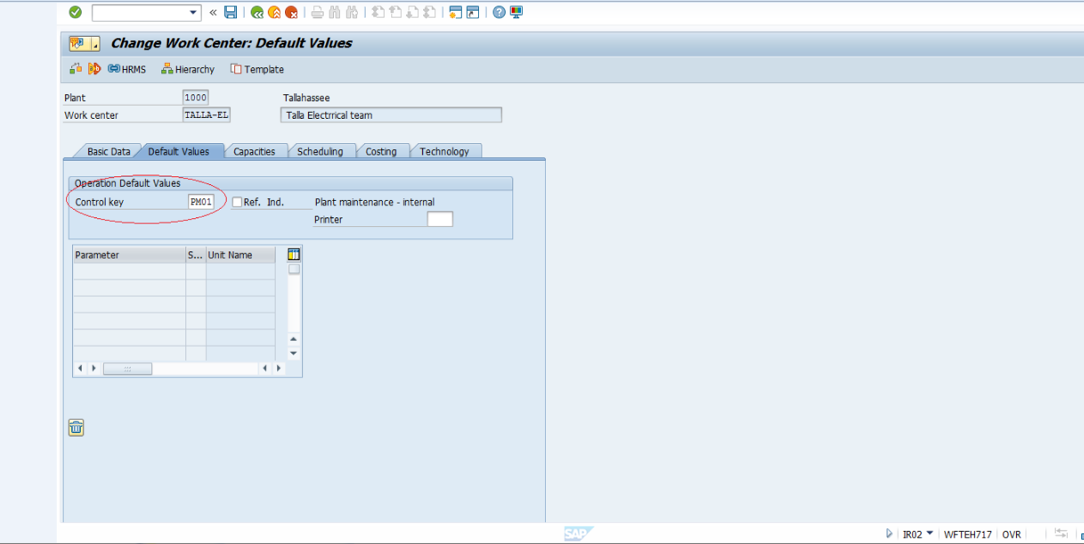

Now, the basic data is done and we need to proceed with the next tab that is related to default values. The screenshot is attached below.

Here the control key should be PM01 because this is an internal work center within a plant. There are also other types of control keys and we will be discussing them later. The next tab is Capacities tab.

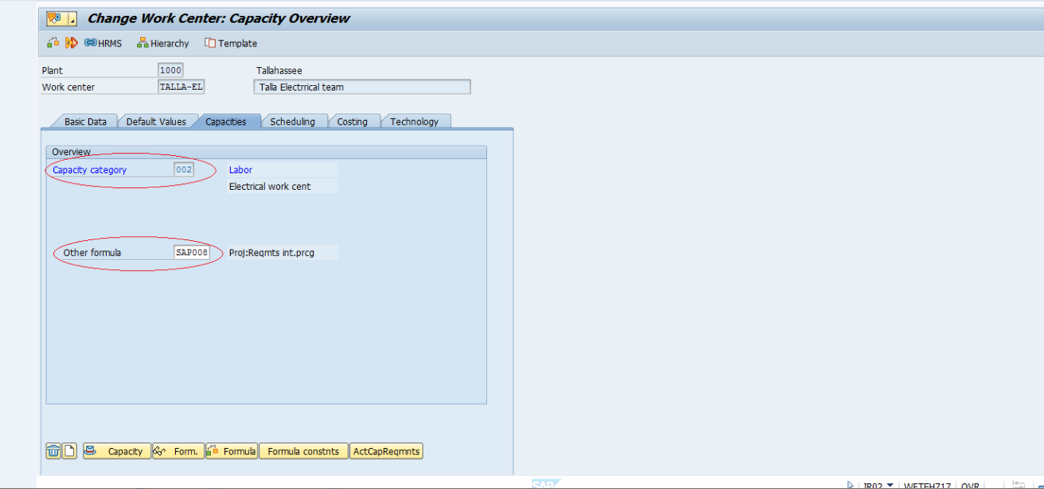

This tab specifies parameters related to the capacity of our work center (head count details in respective work center) in the maintenance plant. Choose other formula as SAP008 and capacity category as 002. Both of them are standard. Now, once we double click on capacity category 002 it will take us to the next screen. Please refer the below screenshot.

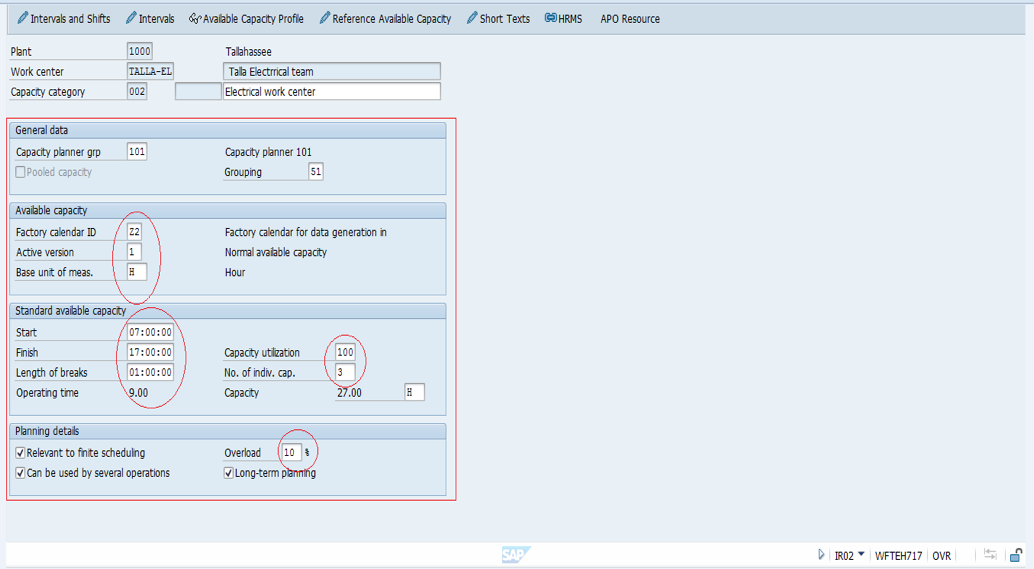

Here in this screen select the appropriate data from dropdowns. The very important points are

- base units of measurement – hours,

- starting and end time of shifts,

- lunch break duration.

Based on this information actual capacity of the work center will be calculated when we are performing the order operation and notification processing.

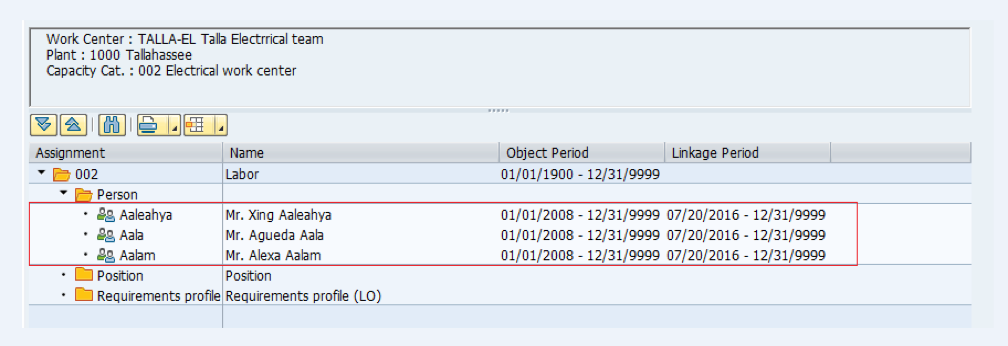

Now, when we click on the HRMS button on the top of the screen, it will take us to the HR directory from where we enter the employee data in the Person folder (employees associated with this particular work center). See the screenshot below which is self explanatory.

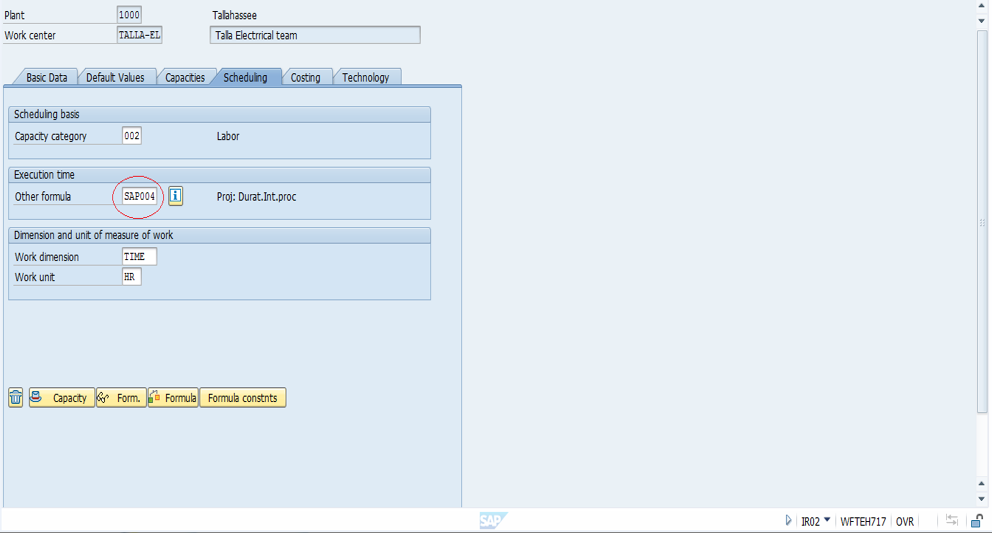

Go back to the tabs of our work center and find the Scheduling tab there. In the scheduling tab, we need to enter only the Other formula as SAP004, whereas other details are automatically copied from the earlier data we entered.

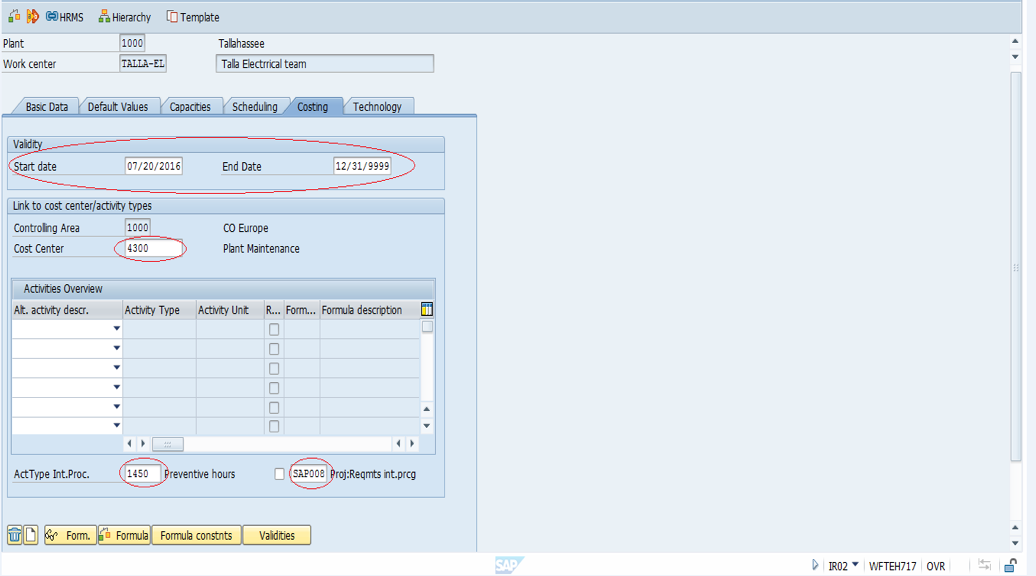

Next, is the costing tab which is very important for the cost calculation related to the maintenance activity in SAP Plant Maintenance.

In this costing tab, after entering the maintenance Cost Center, we have to enter the activity type which is configured by the CO team (costing team). This activity type can be the same for all the work centers or can be different for each of the work centers. Each activity can have different cost per hour configured by the SAP CO consultant. Now, choose the formula for activity type that we entered.

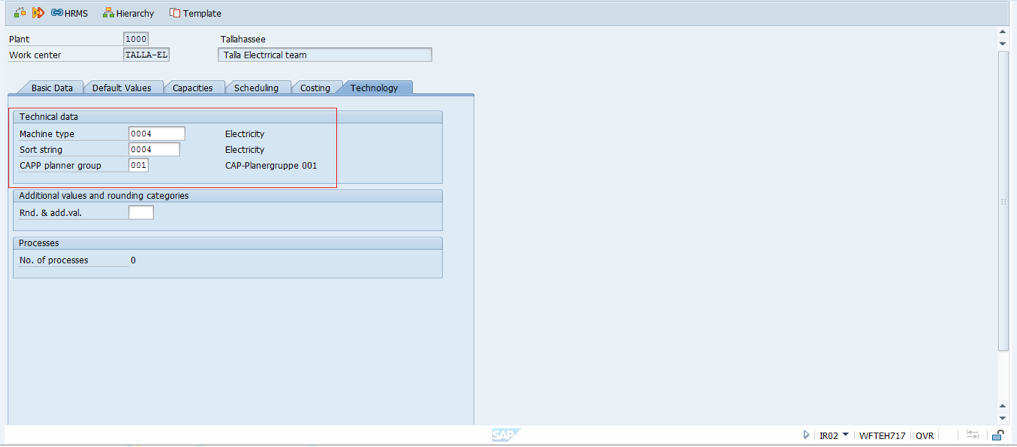

Finally, go to the last tab - Technology tab (see the screenshot below). Choose appropriate data from the dropdown as per the work center type/nature and save it. The work center got saved and you have just successfully created a work center!

Modify SAP Work Center

If we need to modify any of the data in respective tabs, it can be done through the transaction code IR02. When editing a work center make sure that you considered the consequences of changing particular data.

Display SAP Work Center

Any SAP work center can be displayed through the transaction IR03. The SAP system will ask you to enter the work center name and allow you to view its properties without a possibility to change any data. This transaction can be helpful if some employees should only have access to viewing information about SAP work centers and are not allowed to modify them.

SAP PM Work Center Video Tutorial

This video tutorial explains about SAP PM work center and shows how to create it in SAP.

—

Did you like this tutorial? Have any questions or comments? We would love to hear your feedback in the comments section below. It’d be a big help for us, and hopefully it’s something we can address for you in improvement of our free SAP PM tutorials.

Navigation Links

Go to next lesson: SAP Functional Location

Go to previous lesson: SAP PM Organizational Structure

Go to overview of the course: SAP PM Training

Thank you for this helpful tutorial, as you did not mentioned main work center in this tutorial a have a question.

my question is: in my company (sugar factory) we have electrical team, mechanical team and instrumentation team, each team is in turn divided into three planner groups.

ex. electrical section or department is divide to processing electrical team, power generation electrical team and packaging electrical team.

now what about main work center, is the best practice to have one main work center for electrical and mechanical and instrumentation or to have three main work centers?

please note: 1. all centers have share same cost center, 2. processing, power generation and packaging are location (facilities) and not separate plants so we have one planing plant and itself is maintenance plant,

i hope my question is clear.

Thank you soooo much