This tutorial is part of our SAP MM course and it provides SAP MRP process overview. MRP stands for Materials Requirement Planning and it is one of the most important functions of SAP ERP system. This tutorial will help you understand SAP MRP process overview, its outcome, and levels of planning.

This tutorial is part of our SAP MM course and it provides SAP MRP process overview. MRP stands for Materials Requirement Planning and it is one of the most important functions of SAP ERP system. This tutorial will help you understand SAP MRP process overview, its outcome, and levels of planning.

Materials Requirement Planning (MRP)

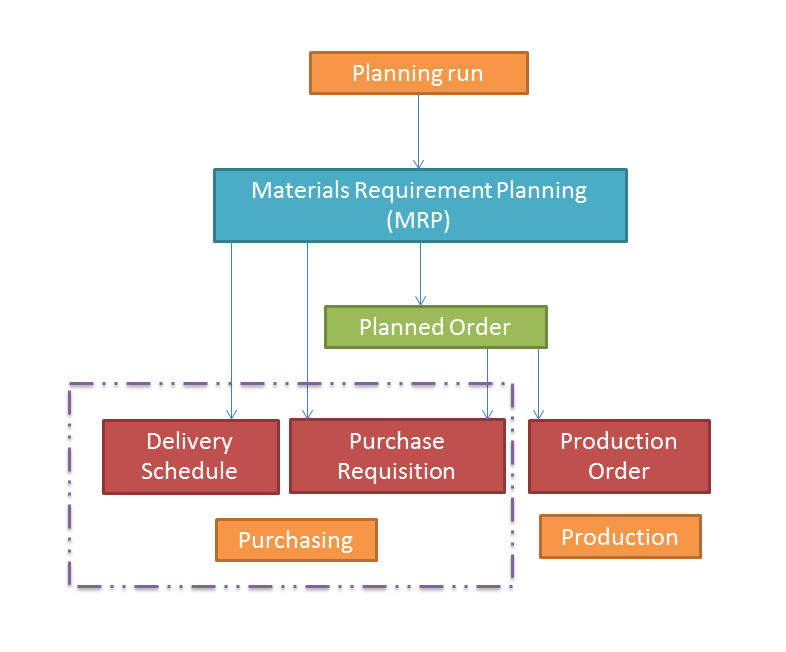

The objective of MRP is to ensure material availability for the requirements. Requirements could be of two types – internal requirements and external requirements. External requirements originate from customer requirements which are entered into SAP as a sales order (for example). Internal requirements are to manufacture components on the same plant which could be supplied as components to finished goods or to satisfy the customer requirements.

SAP MRP checks the stock level of the respective material and generates procurement proposals or planned orders which could be either converted to purchase requisitions or production orders based on the MRP settings in material master records.

Master Data for MRP

The following master data is required to carry out SAP MRP process:

- Material master

- Bills of material

- Work center (in-house production)

- Routings (in-house production)

- Demand management

- Sales and distribution (if required)

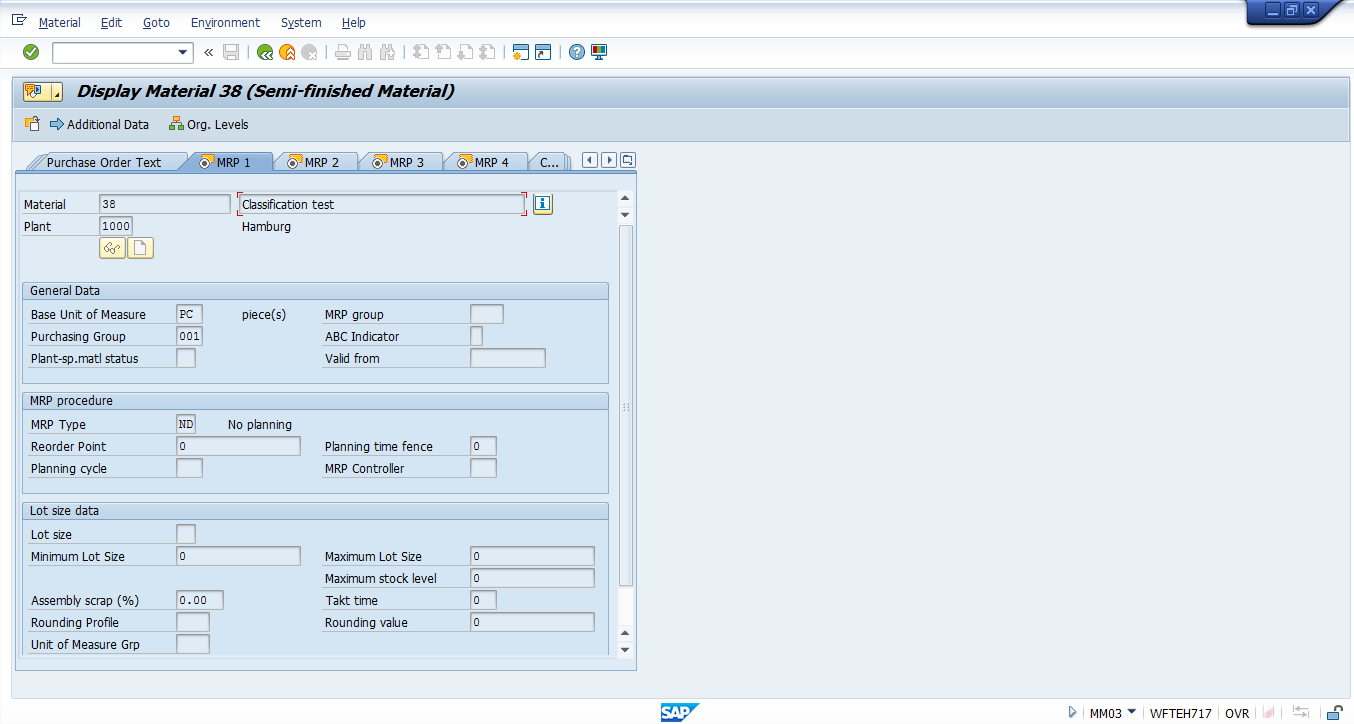

For SAP MRP process to be carried out, material master would need to be maintained accordingly. Material master has several views related to MRP viz. MRP1 to MRP4.

MRP 1 view has fields like purchasing group, plant special material status, MRP procedure, and lot size data.

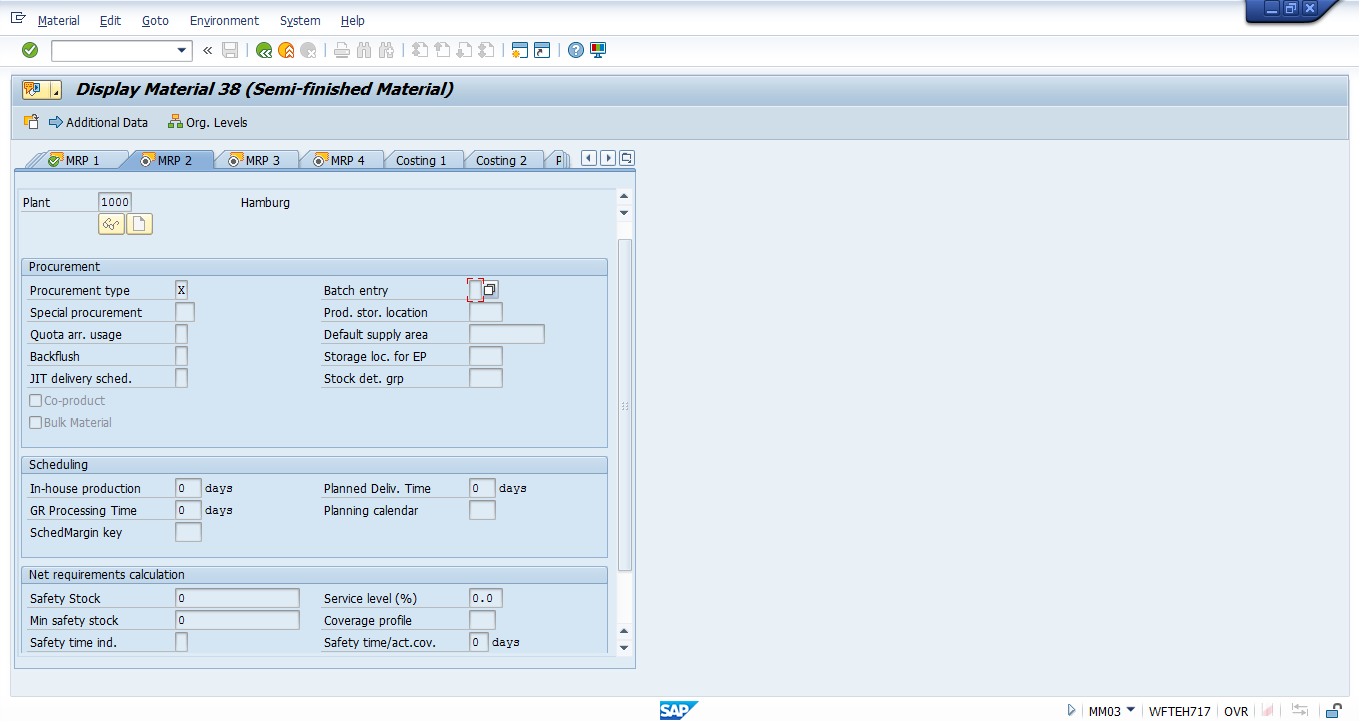

In material master MRP 2 view, fields like procurement type, special procurement, scheduling margin key, and planned delivery time are located. There is a separate tab available for net requirements calculation which includes safety stock, minimum safety stock which helps to calculate the required quantity at the right time.

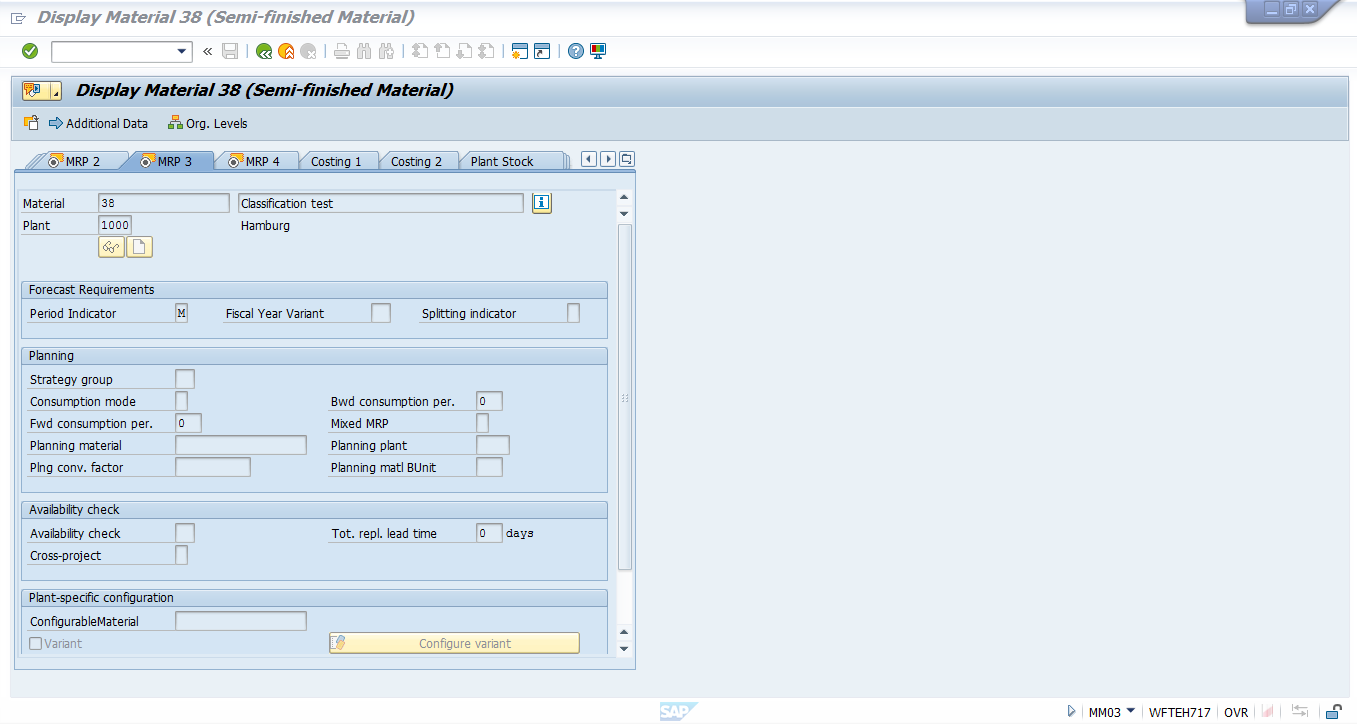

Material master MRP 3 view includes fields like strategy group which is used to decide between Make-To-Order (MTO) or Make-To-Stock (MTS) scenarios.

Also, Availability check filed is available which is used to maintain the checking rule for checking the material availability and update it for available to promise dates and quantities.

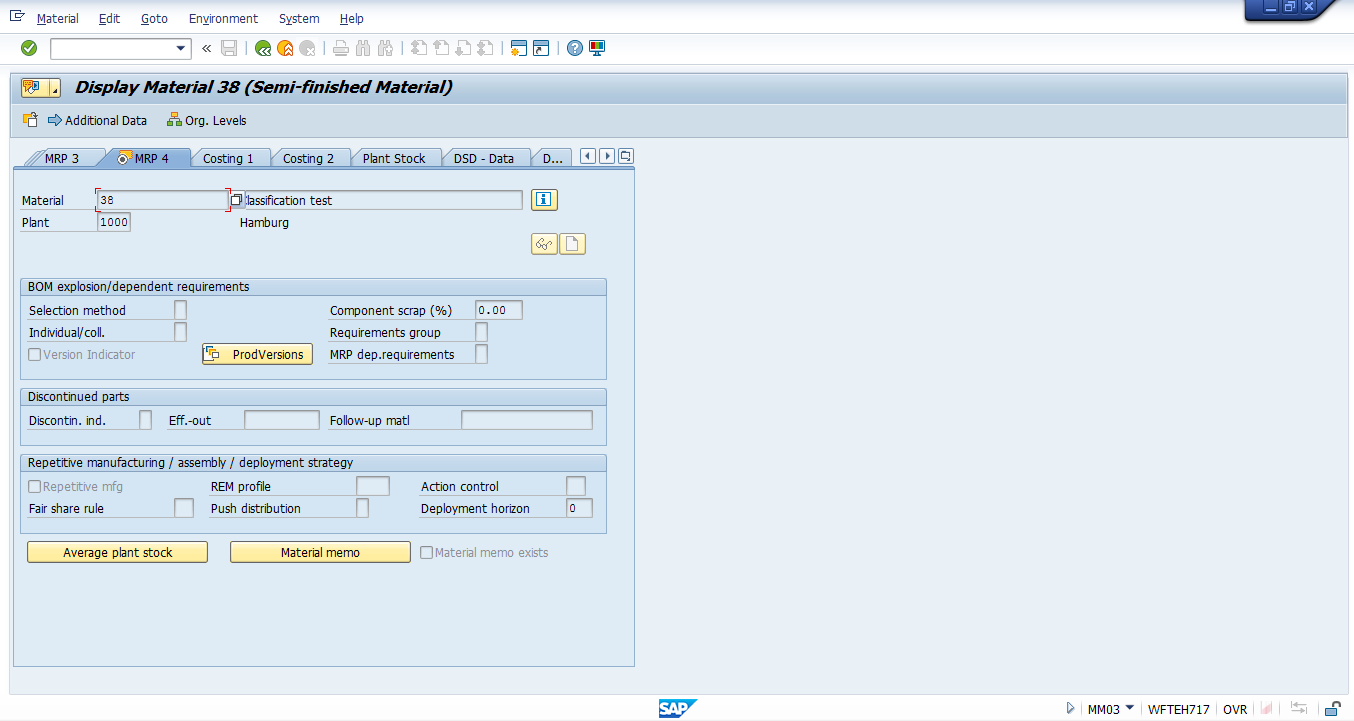

In material master MRP 4 view, fields for BOM explosion and dependent requirements are available. There is a separate tab available for Repetitive Manufacturing which helps to maintain REM profile that is used to enter and record transactions for repetitive manufacturing.

If a material is subject is to in-house production, then work scheduling view would need to be maintained. If a material is subject to MRP planning, then all the four views of MRP would need to be maintained in material master.

SAP MRP Process Flow

SAP MRP process flow starts with customer requirement, which originates from the sales department or marketing department. The customer requirements are entered in SAP via sales orders. The customer requirements are entered as demand in demand management system.

The output of demand management is Planned Independent Requirements which would be used in long-term planning.

Now, materials requirement planning comes into picture. The input to MRP is from sales order and planned independent requirement, if applicable. When the MRP run is carried out, planned order or purchase requisition would be generated based on the planning run settings. Planned order could be converted into purchase requisition (PR) or Production order. Purchase requisition is for external procurement and production order is for in-house production. SAP will then convert all the dependent requirements of planned order into reservations in the production order. When planned order is created for external procurement, it would need to be reviewed by planners, and if required planners would convert the planned order to purchase requisition. Otherwise, the purchase requisition would be generated automatically and available for purchasing.

In SAP MRP process, the system calculates the net requirements while considering available warehouse stock and scheduled receipts from purchasing and production. During MRP process all levels of the bill of material are planned.

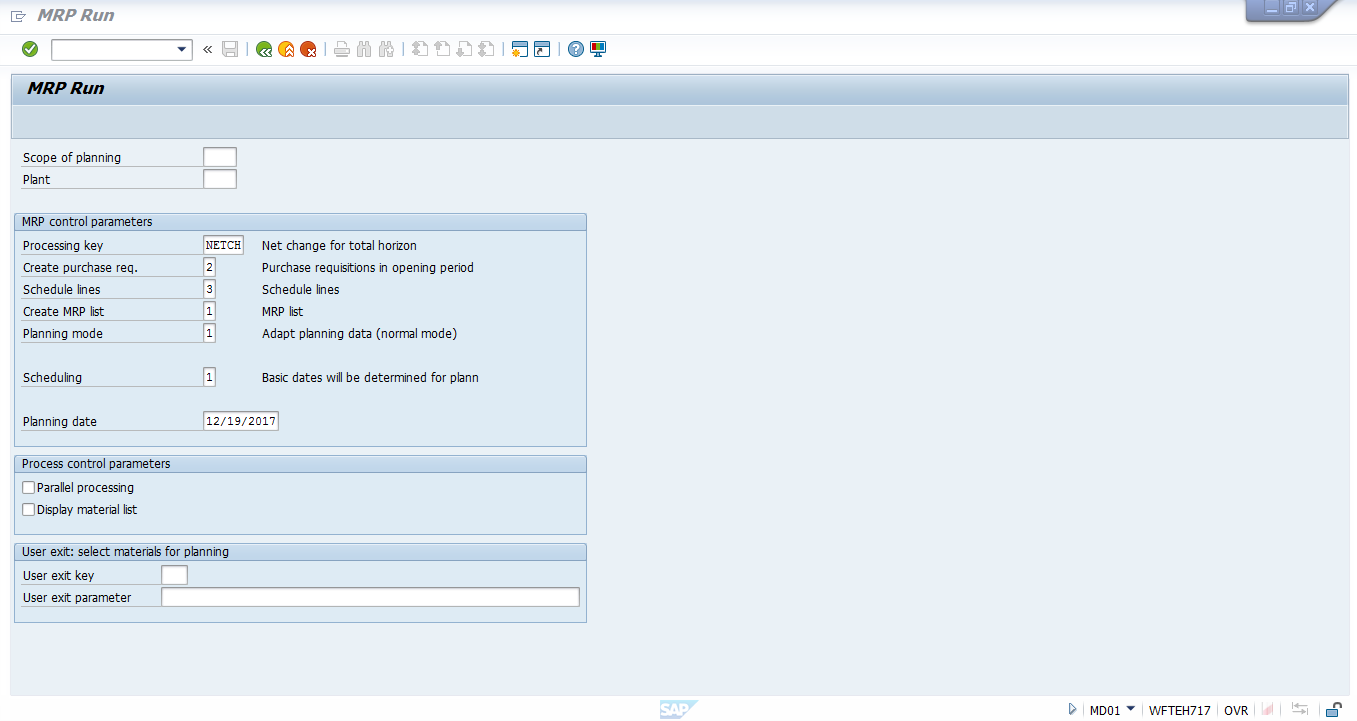

SAP MRP Planning run can be executed at plant level or MRP area level. This planning run can be executed for a single material or a material group. Planning run can be total planning for a plant, single-item single level planning, or multi-level single item planning. The SAP system creates procurement proposals which could be planned orders, purchase requisitions, schedule lines based on the planning run settings. Planning file entry contains details of the materials that are to be included for the MRP run.

SAP MRP Planning run type depends on the processing key in the MRP run screen. There are three types of processing key:

- NETCH – Net change planning in total horizon.

- NETPL – Net change planning in the planning horizon.

- NEUPL – Regenerative planning.

SAP MRP Planning Run

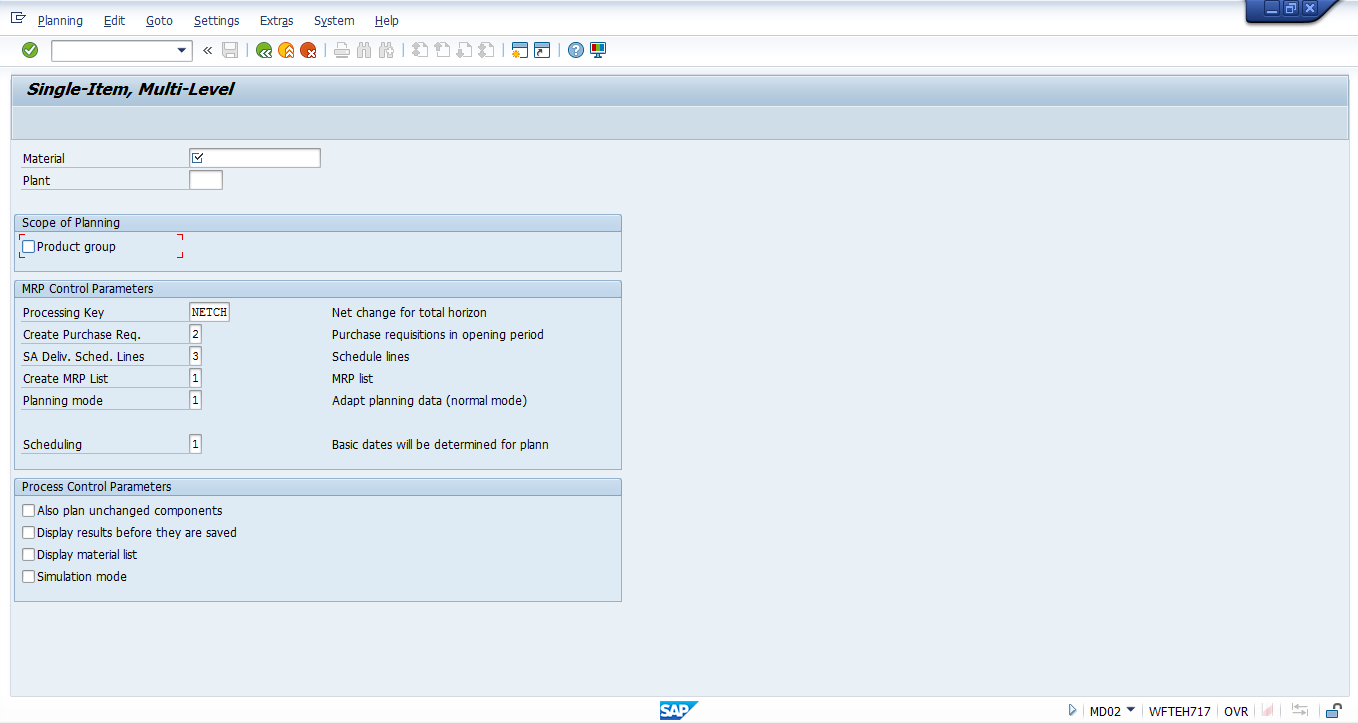

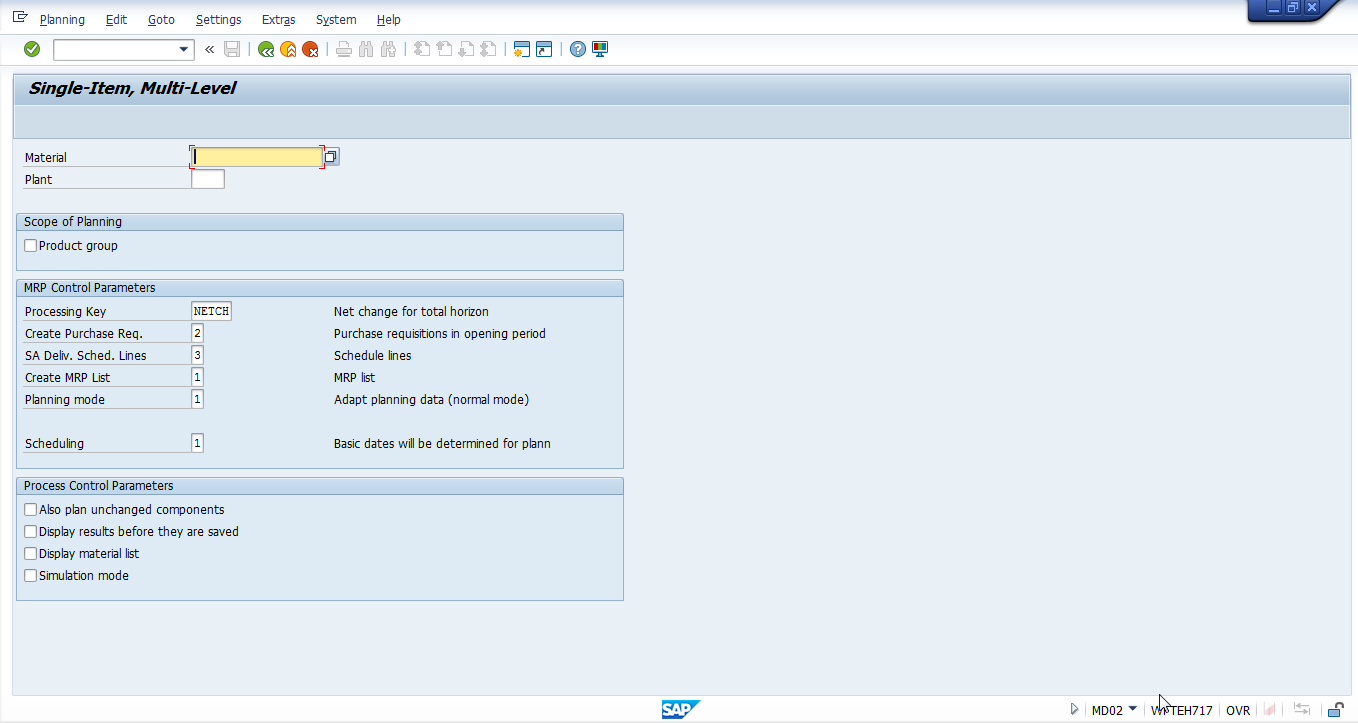

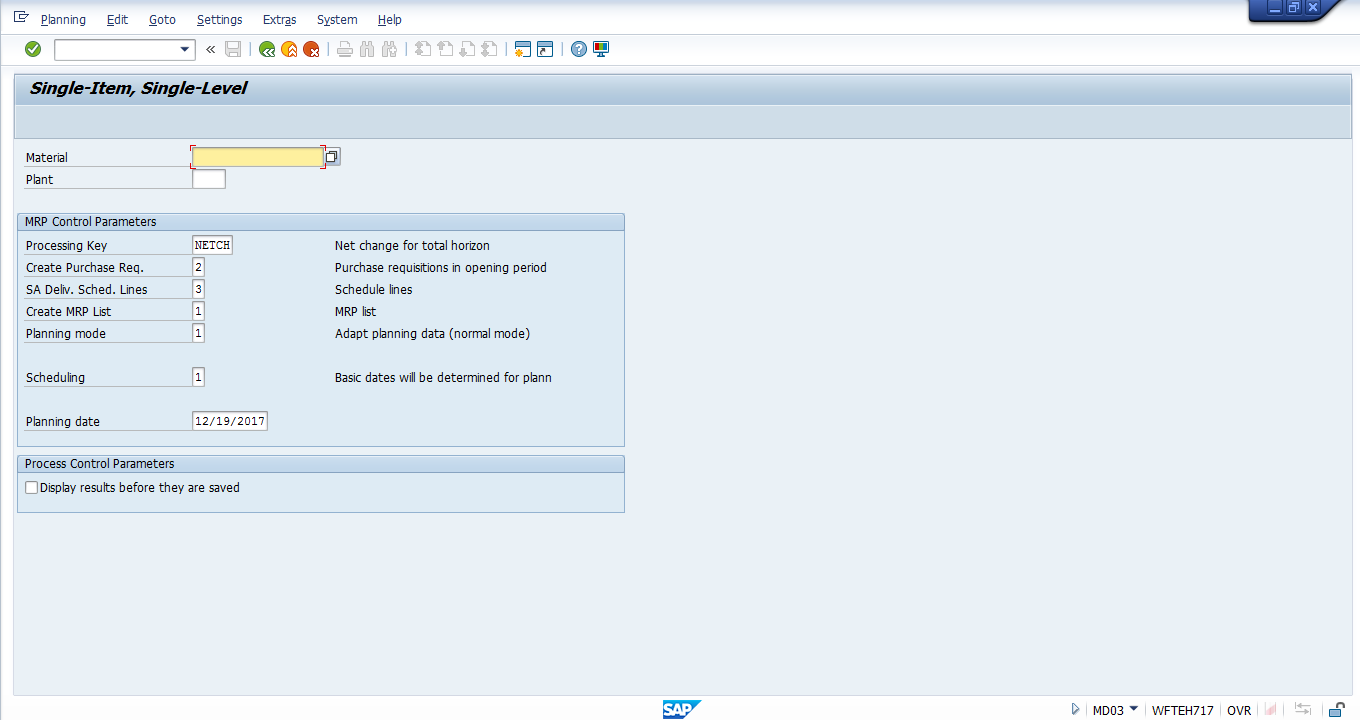

The figure above shows planning run at material level. The material and a respective plant are entered.

There are several fields which come under MRP control parameters control data.

- Processing key field – net change in the planning horizon.

- Create Purchase Requisition – This field has an option for creating purchase requisitions or planned orders.

- Scheduling Agreement (SA) delivery schedule lines – This field has an option for creating schedule lines / no schedule lines. To create a scheduling agreement there should be settings maintained in a source list.

- Create MRP list – MRP list would be created and displayed when the planning run is executed and saved.

- Planning mode – In this field, the planning mode would be maintained whether to run normally or delete and create all planning data or re-explode BOM and routing, if there are any changes made to those master data.

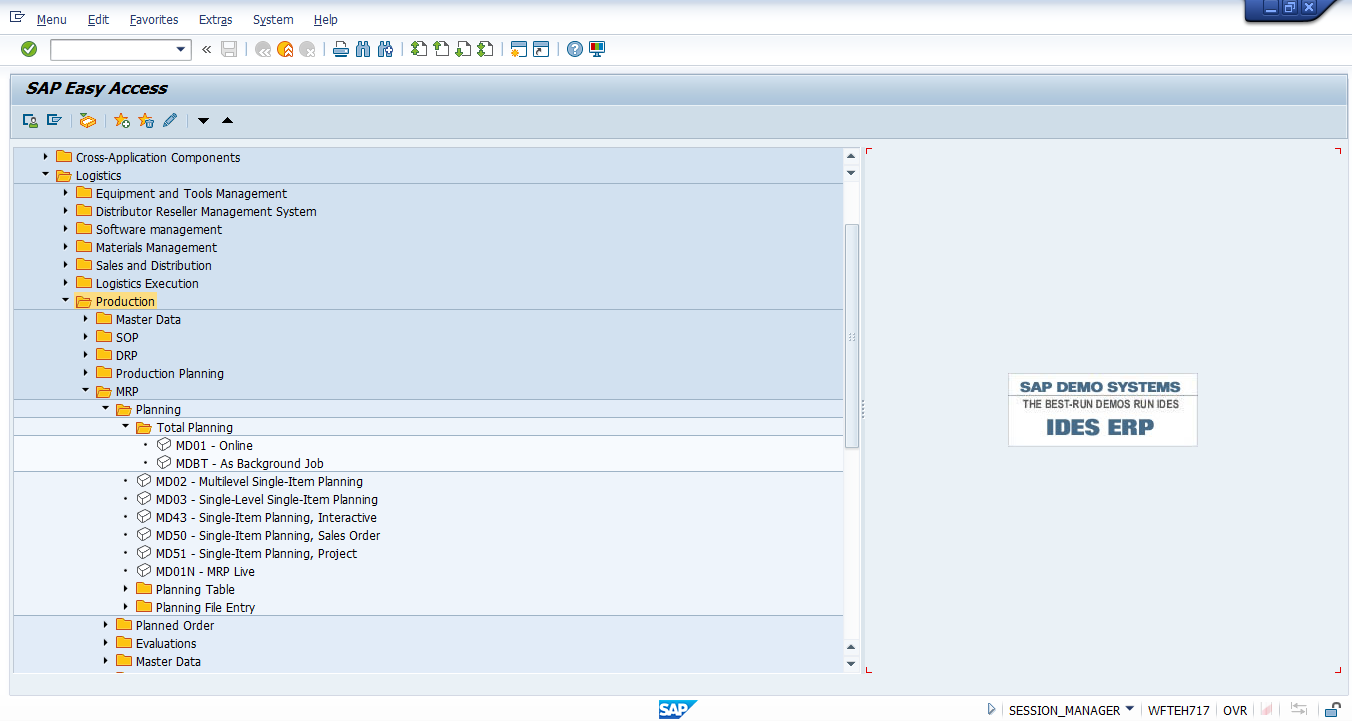

Transactions for SAP MRP Planning Run

Transaction code: MD01

SAP Menu -> Logistics-> Production-> MRP -> Planning -> Total Planning -> Online

With this transaction code, we would be able to carry out planning run at a plant level. As this would consume a lot of time for the output to be displayed, it could be executed as a background job.

MD02 – This transaction code is used to execute a planning run for a material and used to explode multi-level materials.

In this planning run, MRP would be carried for a material and for the first level of BOM, the other components will not be included for planning.

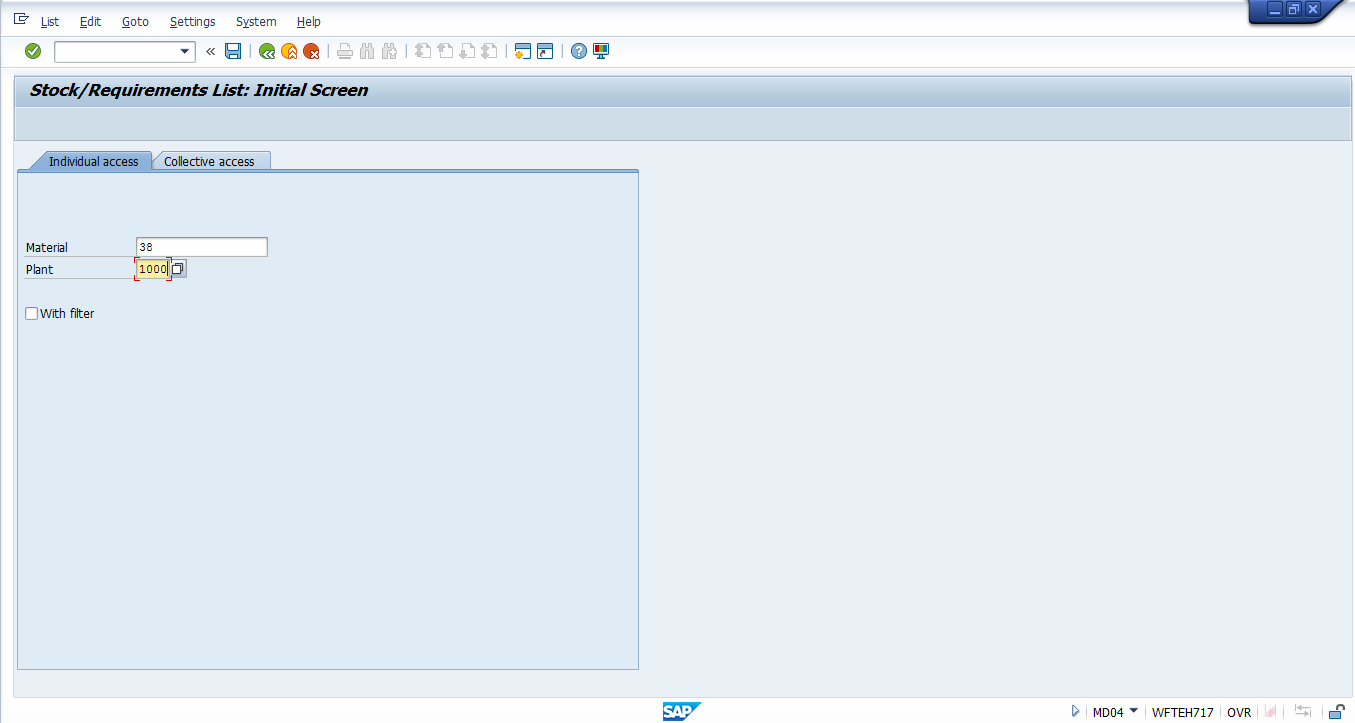

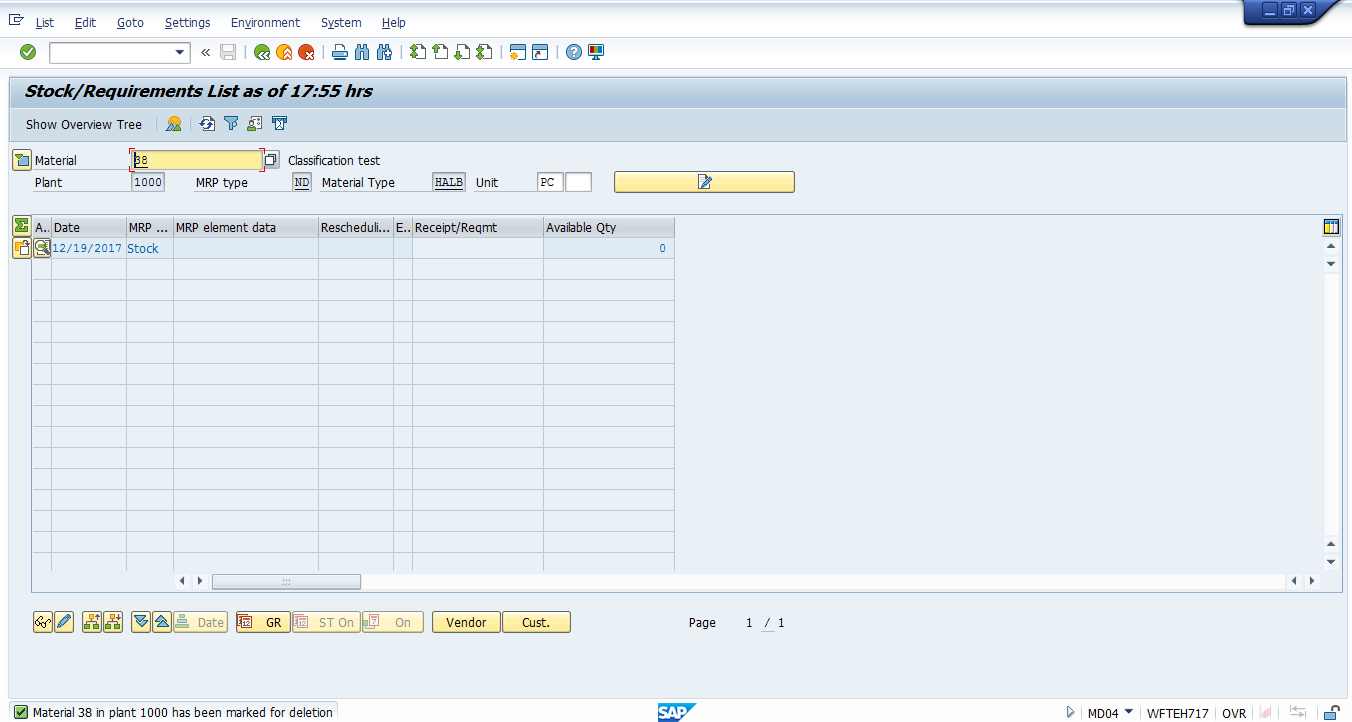

In the transaction code MD04, we could get the latest stock / requirement list for a particular material and plant wise. Enter the material and plant; this would give you the current stock with requirements or receipts.

—

Did you like this SAP MM tutorial? Have any questions or comments? We would love to hear your feedback in the comments section below. It’d be a big help for us, and hopefully it’s something we can address for you in improvement of our free SAP MM tutorials.

Navigation Links

Go to next lesson: SAP MRP vs CBP

Go to previous lesson:

Go to overview of the course: SAP MM Training

Yes,

It is very easy to understand, Transfer of knowledge is excellent and that is the base of Tutorial.

*******

7 🌟

Yes, this gives me a very good understanding of the process, Thank-you

It would be great if you can share the video for same

Plz share videos

hi,

My name is ashokkumar. i am an ECE engineer and i am working in import based company in purchase depart ment. i would like to enter SAP field. i am using SAP software in our company. how can i learn SAP and get job in SAP.

This training did not capture the flow of Single-Item MD02 MRP run. All data turns red and nothing runs when I attempt to update MRP. The most critical part of this function is overlooked??

It is very useful link to understand SAP step by step. Need to go in depth to understand full procurement module.

Gone thru different tutorial websites and found that this is the best theory of MRP process with step by step detailed explanations. Thanks a lot to the team.

This tutorial does not cover. type of MRP and relation between MIN, MAX and safety stocks.

t is very useful link to understand SAP MRP step by step.

MD03 should be highlighted and kept in bold.. MD03 screenshot got e combined into MD02.. there is a mix-up.