SAP EWM is part of the Supply Chain Management Suite of solutions developed by SAP for flexible, automated support for processing goods movements and for managing inventory in the warehouse. This SAP EWM Architecture tutorial talks about various structural elements in EWM, its organization structure, and its role in business processes. Also, it will help to understand the documents which are posted in the EWM system for inbound and outbound processes.

SAP EWM is part of the Supply Chain Management Suite of solutions developed by SAP for flexible, automated support for processing goods movements and for managing inventory in the warehouse. This SAP EWM Architecture tutorial talks about various structural elements in EWM, its organization structure, and its role in business processes. Also, it will help to understand the documents which are posted in the EWM system for inbound and outbound processes.

SAP EWM Architecture Overview

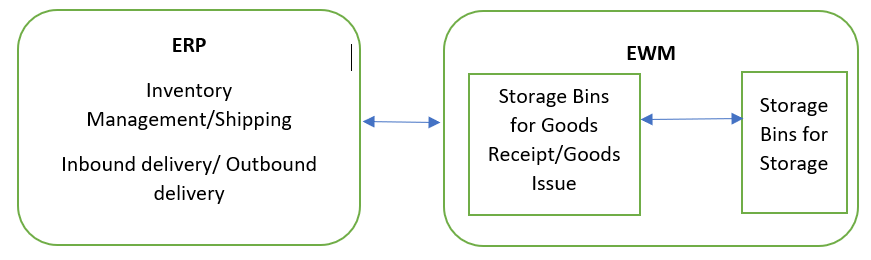

EWM is considered a standalone application that can be used in any warehousing environment. The EWM’s primary functions are to manage the Inventory at the storage bin level, Storage Bin determination for incoming and outgoing goods, and pack the products while shipping them out to customers. SAP EWM comes in two versions: Earlier one has a decentralized structure where it comes in a different box and required interfaces (Core Interface CIF) to exchange master data between ERP and EWM. But with the latest technology of S/4 HANA, EWM and ECC are embedded in one system and CIF is not required.

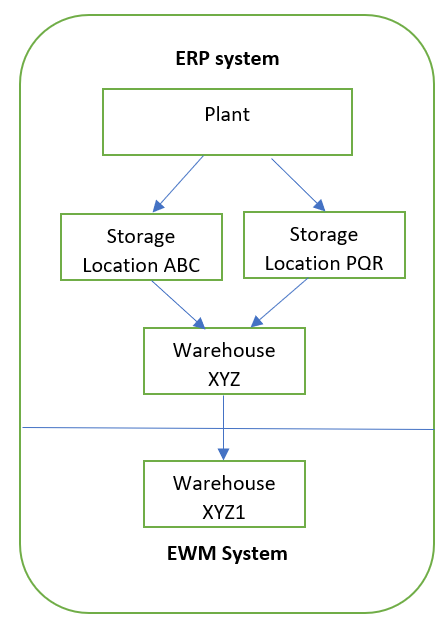

Organization Structure of EWM

To activate warehouse management in the ERP system, a plant and a storage location (for that plant) are linked with the respective warehouse number which will be further assigned to the EWM warehouse number.

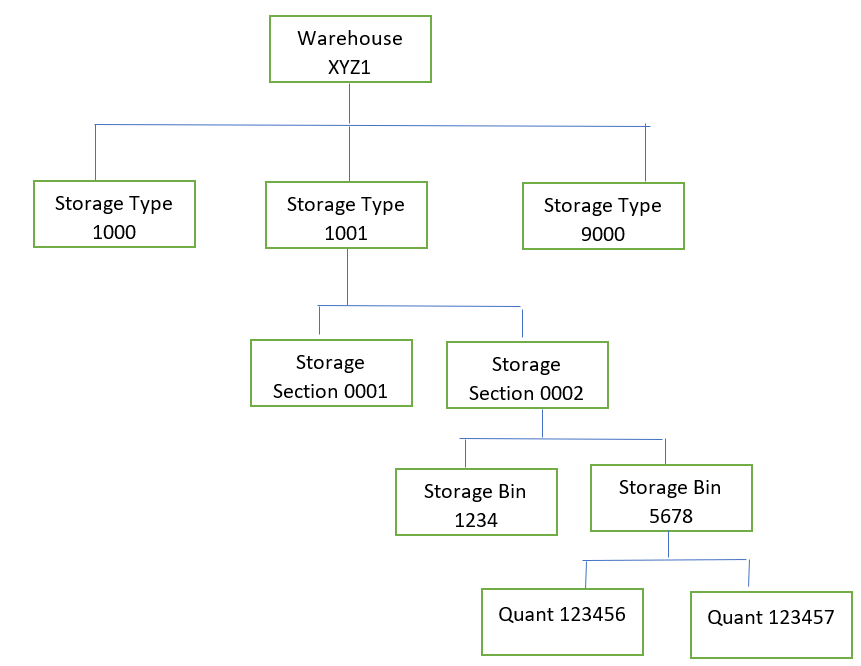

The EWM warehouse has the following structural elements which need to be set up in the EWM system.

Storage Type

A storage type is a further division of the SAP EWM Architecture or its warehouse complex. It is the storage space/facility, technical characteristics, space required within the warehouse. A specific role must be configured for a Storage Type as per its usage. The below table lists down the different roles of a Storage Type and their purposes.

| Standard Storage Type | Purpose |

| Standard Storage Type | Warehouse area where the products are stored. |

| Identification Point | An intermediate area where products are labeled or temporarily placed for some specific purpose. |

| Pick Point | Space in the warehouse where picking/packing activities are performed. |

| Identification & Pick Point | Space which is used for both ID point and Pick point |

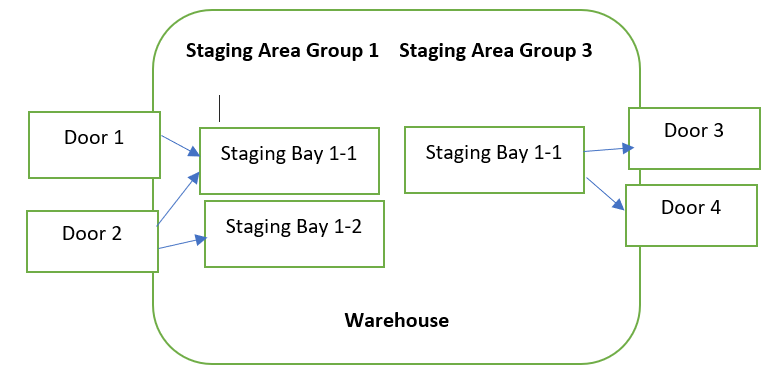

| Staging Area Group | Several staging areas are grouped in staging area group |

| Work Center | Where special processes like counting, quality, deconsolidation, etc., are executed. |

| Door | Where truck arrives for loading/unloading |

Storage Section

Storage type is further divided into storage sections as per its properties. It also joins several bins having similar attributes like heavy, light, fast-moving, slow-moving, etc. It is optional to use the storage section in EWM.

Storage Bins

A storage bin is the smallest addressable unit of space in a warehouse and it represents the exact position in the warehouse at which a product can be stored. This is unique at the warehouse level. Each storage bin has a bin type relating to its properties.

Quant

Quant is the presence or Stock of a specific product with the same characteristics in a storage bin, resource, and transportation unit (TU). Different batches of a product are different quants. Quants can only be created or deleted by the system through movements.

Activity Area

Warehouse activities, for example, putaway, picking, and physical inventory, are executed in activity areas. This allows the sequence of warehouse tasks to be optimized according to the assignment of storage bins to an activity area. An activity area consists of one or more assigned storage bins. Depending on the activity, the same storage bin can be assigned to multiple activity areas. For each activity, the assigned bins are sorted per activity area.

Staging Areas

After unloading or before loading, the material can be stored in an interim storage known as the staging area. A staging area defines a storage section of a storage type with the role “D”. You must configure the activity that is performed in the staging area, that is, define whether it is inbound or outbound or both. Also, it is possible to assign a loading rule. In such a storage section, you can have one or several bins that are also called staging bays for this kind of storage type.

Door

A door in a warehouse can be used for both inbound and outbound shipments. The door from which shipment takes place gets updated in the delivery. Vehicles and Transportation Units drive up to the doors of a warehouse to load or unload goods there. The door can be assigned to a staging area or yard bins.

Work Center

Work Center is a physical unit in a warehouse where the following activities can be performed: Packing, Counting, Quality Inspection, Deconsolidation, VAS, etc. Each work center should be assigned to the warehouse number, storage type, and storage bin.

Supply Chain Unit

Physical or organizational unit that is used within a logistical process in a specific business attribute. E.g.: Goods receipt office or Shipping office.

Custodian

Each warehouse number also requires the assignment to a business partner that represents the custodian. The custodian is someone who stores, manages or further processes stock for another business partner without transfer of title. The custodian only maintains effective possession of the stock, whereas the owner maintains legal possession.

Availability Group

EWM system uses the availability group to determine the stock types and the storage location of the ERP system. We can have different stock types in EWM for one storage location in ERP. EWM determines ERP storage location with respect to the availability group, but the combination should be unique per warehouse.

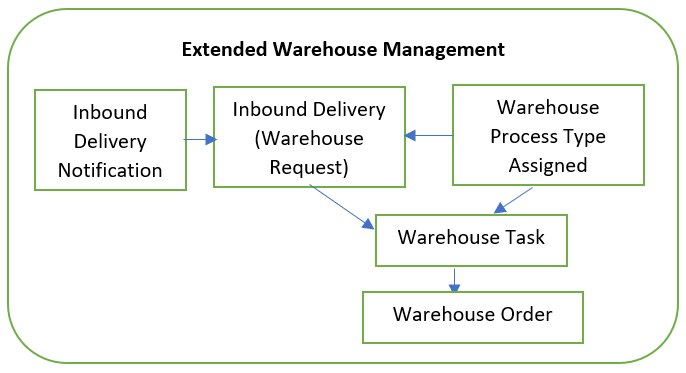

Warehouse Process Type

The warehouse process type (WPT) controls the activity or movement of each process (such as goods receipt, goods issue, posting change) inside the warehouse. A warehouse process type is assigned to every warehouse task document and has various effects on the creation of warehouse tasks.

SAP EWM Architecture Documents

Inbound Delivery Notification

Shipping notification from the supplier is saved in Inbound Delivery Notification (IDN). It contains all the relevant logistics data in the inbound delivery process and is created automatically by an incoming message and served as a reference document to create Inbound Delivery.

Inbound Delivery (Warehouse Request)

It contains all the data required for triggering and monitoring the complete inbound delivery process created automatically after activating the Inbound Delivery Notification.

Outbound Delivery Request

It contains all the relevant logistics data in the outbound delivery process and is created automatically by incoming messages and is served as a reference document to create an outbound delivery order.

Outbound Delivery Order (Warehouse Request)

It contains all the data required for triggering and monitoring the complete outbound delivery process and is created automatically after activating the outbound delivery request.

Posting Change

This is a document containing all the data required to complete the posting change process in EWM. This triggers in EWM as a result of the transfer posting document posted in ERP.

Warehouse Request

This is a document that enables the processing of warehouse activities for a specific product which includes Picking, Putaway, Posting Change, Stock Transfer (within warehouse), Scrapping. The System creates the following type of Warehouse Requests: Inbound delivery, Outbound delivery order, Posting change, Internal stock transfer.

Warehouse Task

This is a document used for executing goods movements that are logical or physical, including pick, putaway, posting change, packing, etc. A warehouse task contains all the necessary information on a planned goods movement what should be moved, which quantity should be moved, from where (source storage bin) should the bin be moved, and to where (destination storage bin). Warehouse tasks are needed for Picking, Putaway, Internal movements, Posting changes, Goods receipt postings, and Goods issue postings.

Warehouse Orders

This is a document that represents an executable work package that a warehouse employee should perform at a specific time. The warehouse order consists of warehouse tasks. Grouping of warehouse tasks into warehouse orders is controlled by Warehouse Order Creation Rules.

Basic Warehousing Processes in SAP EWM Architecture

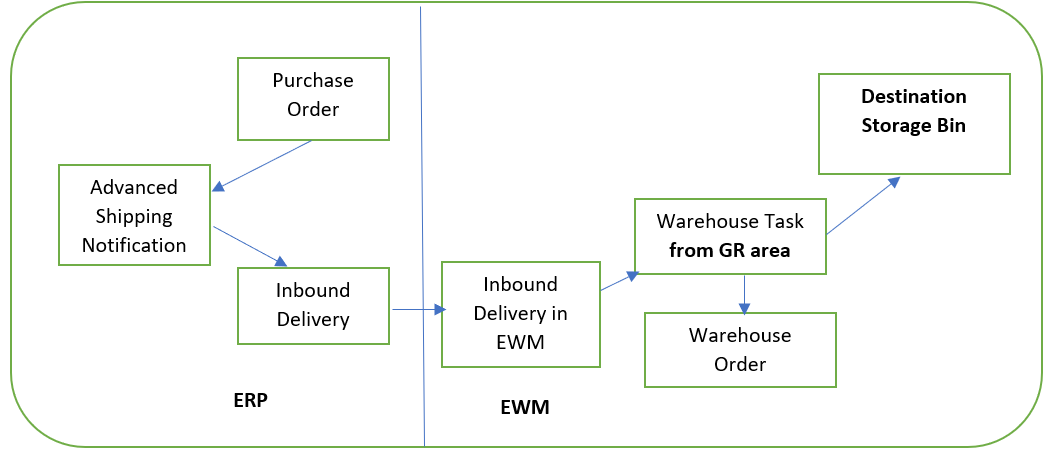

Inbound Goods Receipt Process

The inbound process begins with the creation of an inbound delivery created from the ASN/purchase order in the SAP ERP system. The system determines the SAP EWM architecture for specific settings, such as the warehouse process type, and creates the ID (inbound delivery) in EWM using the post-processing framework (PPF).

The goods received will then be placed into the storage type/storage bin in the warehouse by creating the warehouse task using inbound delivery in EWM.

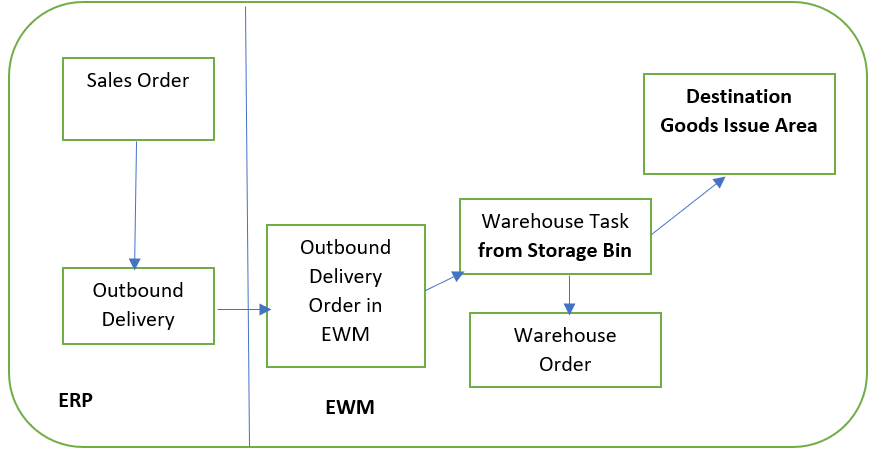

Outbound Goods Issue Process

The process starts with Sales Order and Outbound delivery creation in ERP which creates the outbound delivery order document (ODO) in EWM through PPF action. This document contains additional EWM-relevant data that is determined based on the service profiles associated with the outbound delivery document type and delivery category. This is the warehouse request document for the EWM goods issue process. From the outbound delivery order, the warehouse tasks are created to control the picking and other associated processes such as packing, staging, and loading.

Did you like this tutorial? Have any questions or comments? We would love to hear your feedback in the comments section below. It’d be a big help for us, and hopefully, it’s something we can address for you in the improvement of our free SAP EWM tutorials.

Navigation Links

Go to the next lesson:

Go to the previous lesson: SAP EWM vs WM

Go to the overview of the course: SAP EWM Training

Its really Nice document to understand basic EWM Architecture

Very well done. Thank you.

Hi , very good explanations ! Thank you !

“The process starts with Sales Order and Outbound delivery creation in ERP which creates the outbound

delivery order document (ODO) in EWM through PPF action.” – Is this statement is correct?

I think it will be created through queues.

But i don’t think they use PPF here instead they use Output options to trigger the communication to other system from ECC/S4.

PPF Action is not required to distribute OBD to EWM

Really Nice document for beginners