SAP EWM is part of the Logistics and Supply Chain Module, which offers a wide range of warehousing functionalities for storing, managing, and packing warehouse products and useful in processing the high volume of goods movements in and out of the warehouse. This document talks about SAP EWM Putaway Process Steps – which is to place the product in the destination bin in storage type when the goods receipt is posted in EWM.

SAP EWM is part of the Logistics and Supply Chain Module, which offers a wide range of warehousing functionalities for storing, managing, and packing warehouse products and useful in processing the high volume of goods movements in and out of the warehouse. This document talks about SAP EWM Putaway Process Steps – which is to place the product in the destination bin in storage type when the goods receipt is posted in EWM.

The EWM structural elements, hierarchy, and roles of each element were explained in one of our previous tutorials. Please refer to this tutorial on SAP EWM Architecture.

SAP EWM Putaway Process

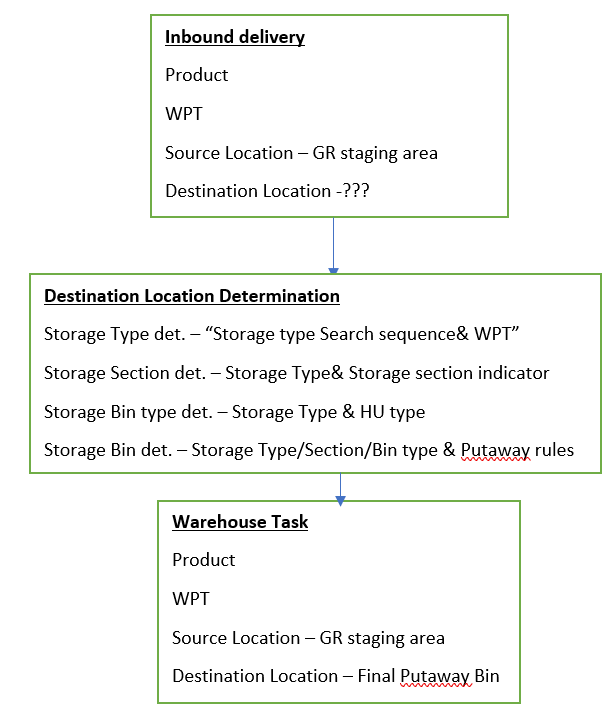

SAP EWM Putaway refers to the warehouse processes that take place after receiving an inbound shipment of products from a vendor, another company warehouse or a production line and having it all stored away in racks and shelves in the warehouse. In the below diagram, we can see that the stock is received in the goods receipt staging area, and based on the setup in the EWM, the system finds a suitable bin to put away the product.

Inbound Process in EWM

The inbound process begins with creating an inbound delivery from the following business processes originated in ERP:

- Vendor Purchase Order – the receipt of the goods with reference to Vendor PO creates an inbound delivery to put away the products in raw material storage type/bin.

- Stock Transport Orders – Moving the products within an organization where the supplying plant issues it, and during receipt at the receiving side, creates an inbound delivery to put away the products in the warehouse bin.

- Customer Returns Order – the Returns Order is created in ERP if the product shipped to the customers does not meet expectations. Such products are to be returned to the warehouse and put away in the bin.

- Production Order – the Production Order goods receipt posted at the production line creates an inbound delivery to put away products in the warehouse for shipment to the customer.

The system determines the EWM specific settings, such as the warehouse process type, and creates the ID (inbound delivery) in EWM using the post-processing framework (PPF).

The goods receipt will then be posted to receive the products in a Goods Receipt Zone, and then finally put away into the destination bin based on the search strategies and determination process.

Documents Generated in EWM During Putaway Process:

Inbound Delivery (Warehouse Request)

It is a document that enables the processing of putaway activity for a specific product.

Warehouse Task

It is a document used for executing goods movements for putaway. A warehouse task contains all the necessary information on a planned goods movement: what should be moved, which quantity should be moved, from where (source storage bin) should the bin be moved, and to where (destination storage bin).

Warehouse Orders

It is a document that represents an executable work package that a warehouse employee should perform at a specific time. A warehouse order consists of warehouse tasks and is assigned to a worker to execute the putaway process as per warehouse tasks.

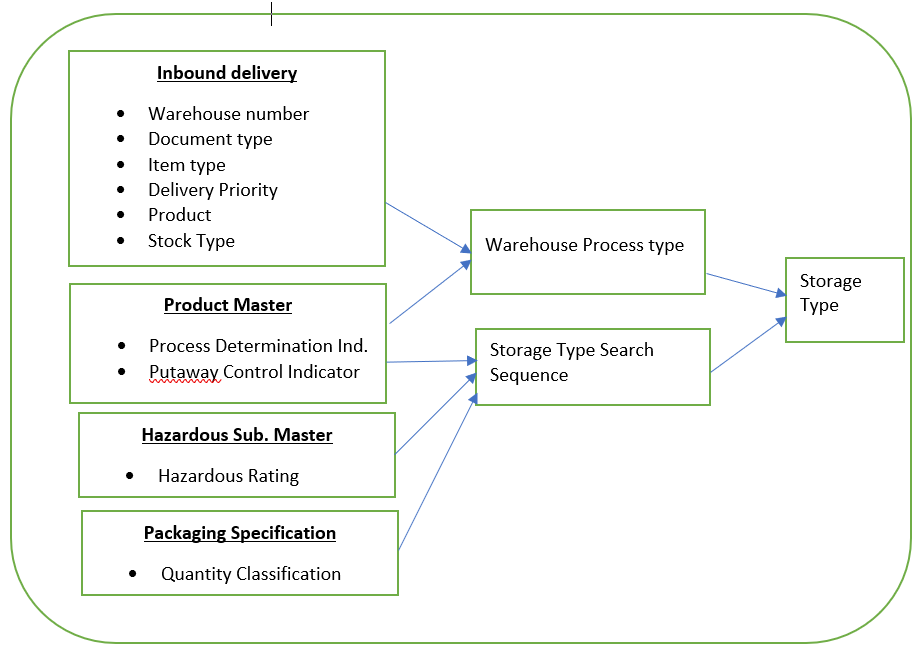

Destination Bin Determination in SAP EWM Putaway Process

The various steps in the EWM putaway process are explained below:

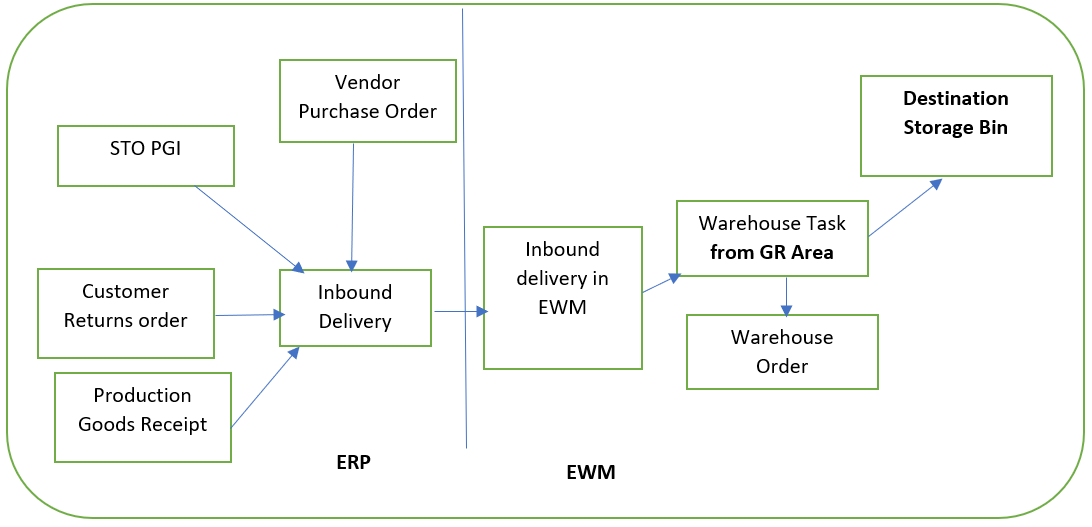

Step 1: Storage Type Determination

The first step to determine the destination storage bin for putaway is to know the destination storage type.

Storage type is maintained and determined from the storage type search sequence as per the configuration. This configuration is based on several attributes like warehouse process type, putaway control indicator (maintained in the product master), hazardous substances master data and packaging specifications. The system determines warehouse process type based on warehouse number, document type, item type, delivery priority, product, and stock type from the inbound delivery document. All these attributes and the storage type determination process is shown in the diagram below.

The storage type search sequence contains the list of storage types that can be searched, as per the sequence configured to determine the storage bins. If the storage type determined contains more than one storage section, the system proceeds to determine the destination storage section.

Step 2: Storage Section Determination

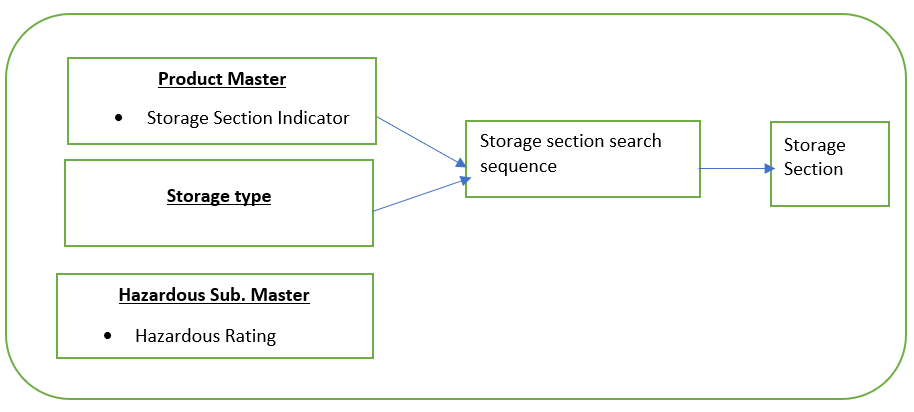

In the process of storage section determination, the system will look for:

- The storage type (which was first determined in the above step),

- The storage section indicator (which is maintained in the warehouse product master), and

- The hazardous attributes.

One or more of these attributes can be used to determine the storage section, as per the configuration maintained in the determination table. This process is illustrated in the following figure:

Step 3: Storage Bin Type Determination

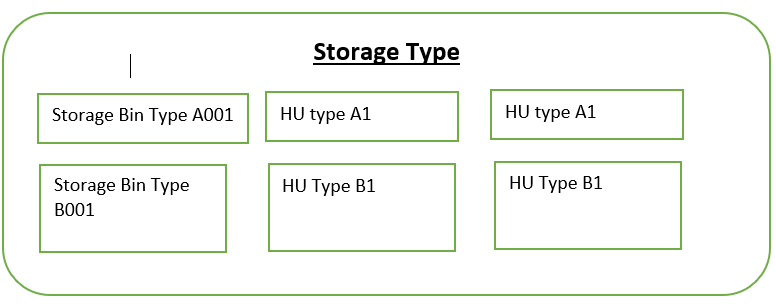

In the next step, the system determines the bin type, which the destination bin should have as per the size of the pallet or handling units on which the material comes in the inbound shipment. The storage bin types are assigned to handling unit types and to storage types in the configuration. The HU types are determined based on the packaging specification.

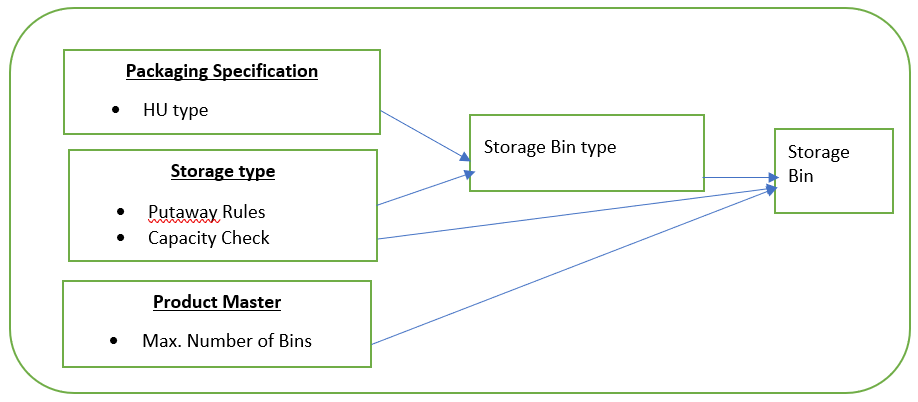

Step 4: Storage Bin Determination

After the system determined the storage type, the storage section, and the storage bin type, the system searches for a putaway bin to place the product quantity. This bin is determined based on the putaway rule (or strategy), and capacity checking. The process is illustrated in the following figure:

If after checking all the bins in the determined storage type/storage section/storage bin type the system cannot find a suitable bin, it then goes further to the next storage type -> storage section -> storage bin type and searches there for a suitable bin as per the putaway rule/strategy as explained in a separate section below.

SAP EWM Putaway Strategies

The destination storage bin in step 4 of the EWM Putaway Process is determined according to SAP putaway strategies (or rules). SAP EWM putaway strategy or rule is a technique used to determine a suitable bin in order to place the product quantity there. This determination is based on the characteristics of the product and the section in which the bins are located. In SAP EWM, putaway strategies are configured, by one or more of the below fields in the storage type definition:

- Storage Behavior – this specifies the general structure of the storage type. The various parameters include the following:

- Blank – standard – the bins in this storage type represent a general area for storage.

- Pallet storage – here, the system processes different handling unit (HU) types like pallets and then assigns them to suitable sections of a storage bin.

- Bulk storage – this allows to place several pallets in one storage bin. This is used for products that are managed in large quantities and thus occupies a large amount of storage space.

- Putaway Rule – this specifies the logic that the system uses to find out a suitable destination bin during putaway. The various parameters include the following:

- Empty Bin – the system only searches for available empty bins.

- Addition to Existing Stock/Empty Bin – the system searches first for partially occupied bins. If it doesn’t find one, then it looks for empty bins.

- General Storage Area – this is used when there is only one storage bin for each storage section, and that permits additions to existing stock as well as mixed storage of all types.

- WT Generic – based on the configuration set up in storage type, the below destination data is determined during warehouse task creation:

- Destination storage type

- Destination storage type and destination storage section

- Destination storage type, destination storage section, and destination storage bin

The destination storage bin is then finally determined when the warehouse employee confirms the WT.

Final Notes

The SAP EWM putaway process we learned above plays a key role in managing inventory in the warehouse. It is very important to properly store products in the warehouse based on their size, characteristics, the volume of goods movement, etc. which in turn, helps in the subsequent outbound process of stock removal and harmonizes the entire supply chain process in business.

—

Did you like this tutorial? Have any questions or comments? We would love to hear your feedback in the comments section below. It’d be a big help for us, and hopefully, it’s something we can address for you in the improvement of our free SAP EWM tutorials.

Navigation Links

Go to next lesson:

Go to previous lesson: SAP EWM Architecture

Go to overview of the course: SAP EWM Training

Excelente Tutorial ,,…tengo una pregunta estoy practicando en un servidor S4 HANA 2020 y tengo un problema con el retorno inmediato desde EWM a ERP cuando se confirma totalmente la recepción de los productos en EWM puedo visualizar el stock disponible pero en ERP cuando consulto por la TRX MMBE o MB51 para ver el doc contabilizado inclusive por la VL33N flujo de documentos no se visualiza nada de los movimientos realizados. Por favor me podría indicar que debo verificar o que parámetro me falta customizar para que retorne la información a ERP ……en la definición para el almacén EWM indica en forma inmediata.

Gracias

Freddy Retto Torres