This tutorial is part of our SAP MM course and it provides information about SAP MRP procedures. This tutorial will mention different SAP MRP procedures and explain their features.

This tutorial is part of our SAP MM course and it provides information about SAP MRP procedures. This tutorial will mention different SAP MRP procedures and explain their features.

SAP MRP Procedures

The main function of Material Requirement Planning (MRP) is to ensure the availability of the required quantity of material(s) at the right time. The material should be made available for requirements like sales orders, planned independent requirements, dependent requirements which arise out of BOM explosion during planning run, or reservations. MRP is executed to calculate the net requirement calculation which arrives after calculating the warehouse stock and the receipts. For this purpose we could use MRP or consumption-based planning (CBP) procedures. The main difference MRP and CBP is on the net requirements calculation. MRP performs net requirements calculation based on the current and future requirements like sales orders, dependent requirements, etc. On the other hand, CBP calculates net requirement based only on the past consumption data or forecasted data.

SAP MRP procedures can be classified into two major types:

- Consumption-Based Planning (CBP)

- Material Requirements Planning (MRP)

CBP includes the following procedures:

- Reorder point planning

- Forecast-based planning

- Time-phased planning

Reorder Point Planning

In reorder point planning, there comes a concept called reorder point. This is the point where the requirement is triggered either for the procurement proposals or in-house production. The reorder point triggers the procurement proposals when the material stock and receipts fall below the reorder point.

The time taken by material to be available for requirement, either for in-house production or external procurement is called replenishment lead time. When calculating the reorder point SAP system would include the material requirements during replenish lead time.

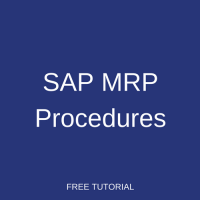

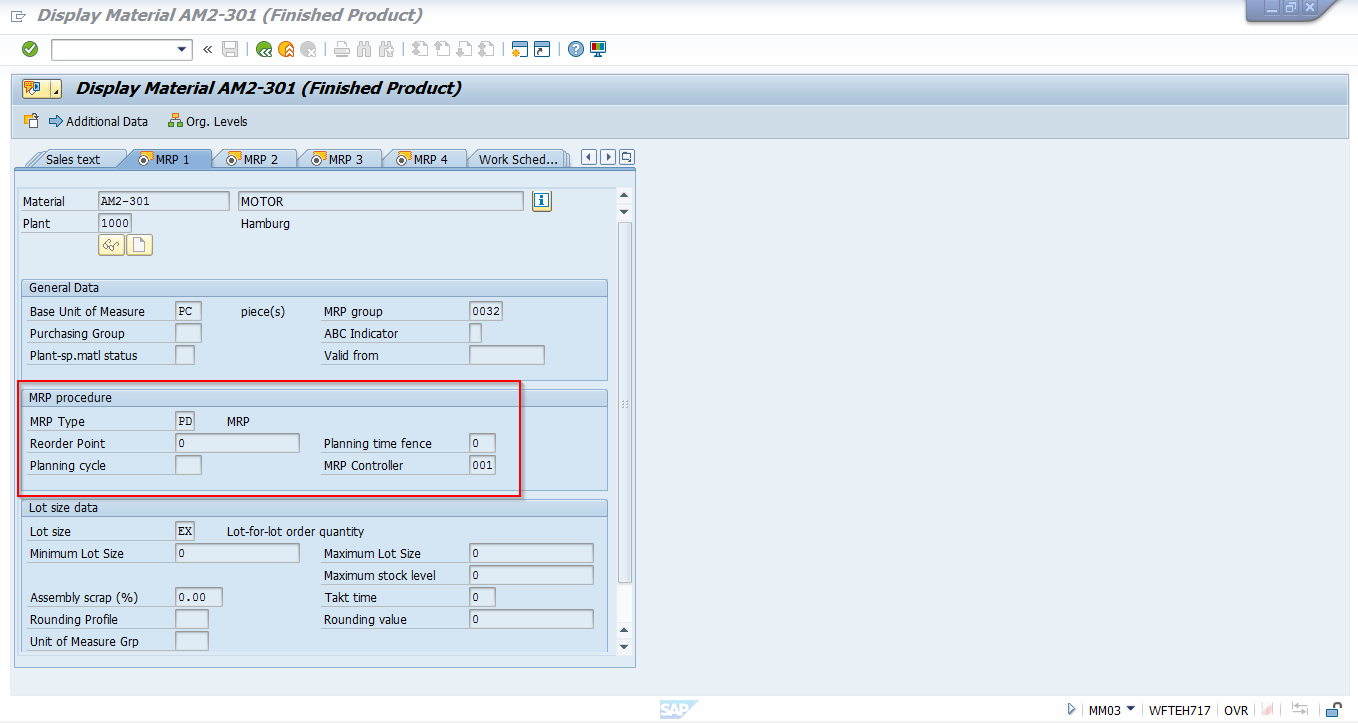

Net requirements calculation also takes into account safety stock. Safety stock is the stock which includes material requirements and any unexpected deviations from planned or unexpected delays in delivery. Safety stock would be maintained in MRP 2 view of a material master record under net requirements calculation tab.

Reorder point planning could be further classified into manual and automatic reorder point planning.

Manual reorder point planning requires the reorder point and safety stock to be determined and entered in the material master record manually. MRP controller calculates these values and enters in the material master record manually. These values are then used during planning run calculation of the net requirements and trigger procurement proposals.

Automatic reorder point planning ensures that the reorder level and safety stock are calculated automatically by the historical consumption data. The historical consumption data would be used to calculate the future requirements through a forecast program. The future requirements, i.e. forecast values, are used to calculate the reorder level and safety stock.

Forecast-Based Planning

Forecast-based planning procedure is based on the historical material consumption data. The future requirements are calculated with the forecast program that calculates future requirements with the forecast value and consumption values. The calculated value would be considered during a planning run. This procedure which is used to calculate the requirements is executed in a specified interval. If there is any material consumed during this interval, then that particular material should be reduced from the forecast requirement so that those quantities or the requirement is not considered during planning run.

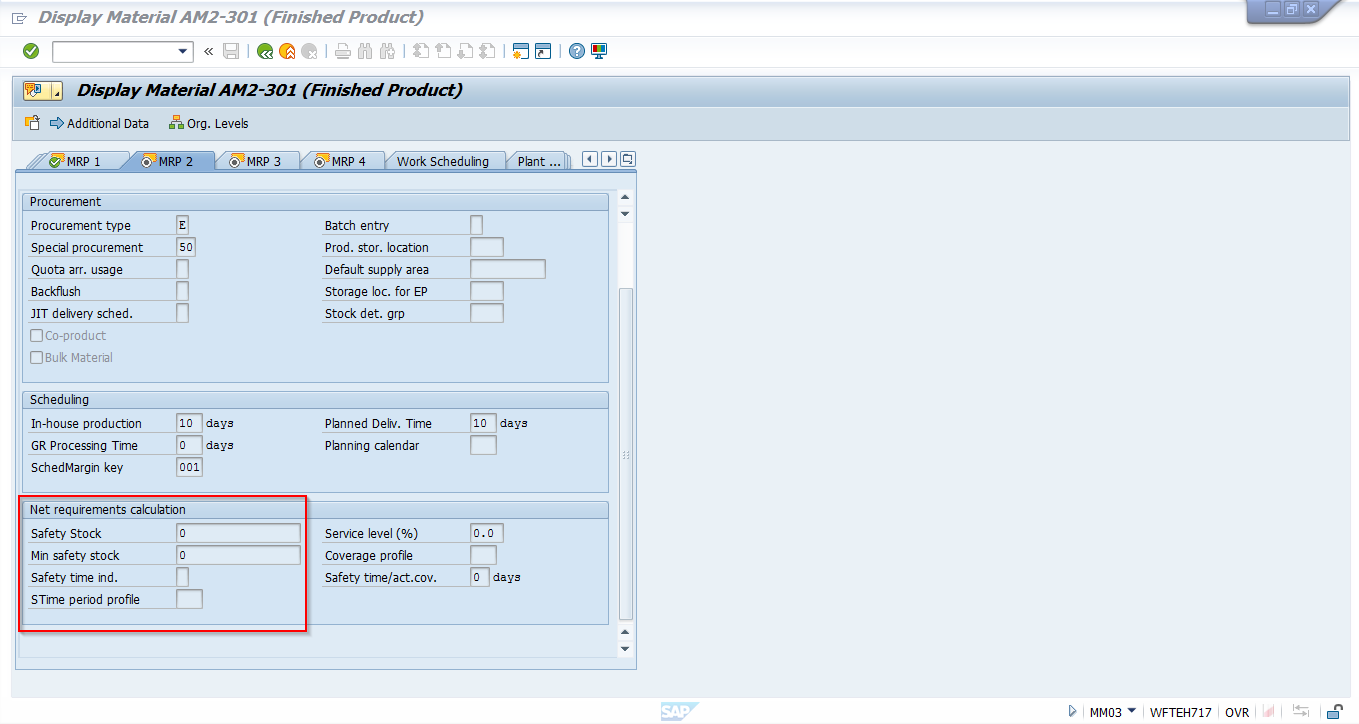

The consumption values are maintained in additional data under “Consumption” view. It consists of a period indicator field, which has options for settings period intervals. The period intervals that are commonly maintained are daily, weekly and monthly. The period indicator in the above figure has the value as “T” which is the key for daily. So, if you look at the table for consumption values in the figure, the period is maintained on a daily basis. The consumption values are entered in the material master on a daily basis. If there is any deviation in the planned delivery or production schedule, then it could be entered in the corrected value. While calculating net requirements all periods are included to generate the procurement proposal. The quantity for the proposal is calculated based on the lot-sizing procedure that is maintained in the lot size data of the material master record MRP1 view. The proposals would then be converted to either a purchase order or a planned order. The date for the conversion of the proposals to order would be calculated by the system. So, this planning procedure would be used to ensure the availability of stock against the requirements at the right time with the right quantity.

Time-Phased Planning

Let’s discuss the next one of SAP MRP procedures. As the name suggests, this planning procedure performs planning for a particular day. For instance, if the material is supplied by a vendor only a specified day or days in a week, this material could be planned based on the days in which it would be delivered by the vendor.

This time-phased planning procedure requires the material to be maintained with an MRP date in the planning file. The date could be entered during material master creation and the same would be changed or reset after every planning run has been executed. The date which is reset or changed is calculated with the help of a planning cycle that is maintained under MRP procedure tab in MRP1 view of the material master.

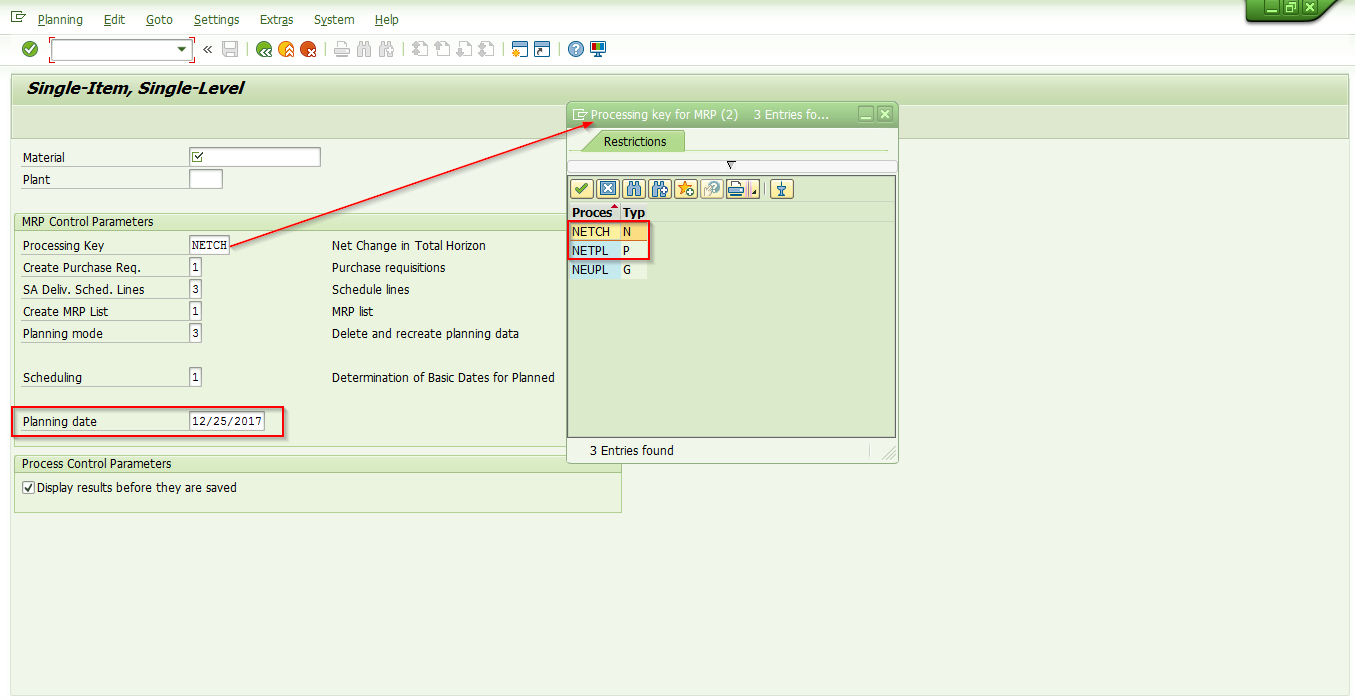

The above figure shows the planning run for a single item, single level planning. There is a processing key available for the planning run. The keys N and P marked above, which could be described as net change planning indicator and net change planning horizon indicator respectively, are not applicable for time-phased planning. Therefore, only G – regenerative planning is applicable for time-phased planning procedure.

There is another field marked above – planning date. This field indicates the date on which the planning run would be carried out.

Planning date field is very significant for the time-phased planning. As this planning procedure runs on a planning cycle and plans requirements based on the day the material would be delivered, this planning date field helps the planning run to be executed on an earlier date if required by business in case of any deviation in the delivery schedule.

—

Did you like this SAP MM tutorial? Have any questions or comments? We would love to hear your feedback in the comments section below. It’d be a big help for us, and hopefully it’s something we can address for you in improvement of our free SAP MM tutorials.

Navigation Links

Go to next lesson: SAP MRP Types

Go to previous lesson:

Go to overview of the course: SAP MM Training

I have one question. If we select MRP type is VB then system considered customer order ?