This tutorial is part of our SAP MM course and it aims to explain the functionality of SAP Reorder Point Planning. After completing this tutorial, you should understand SAP reorder point planning which is an MRP (Material Requirement Planning) procedure in Consumption Based Planning.

This tutorial is part of our SAP MM course and it aims to explain the functionality of SAP Reorder Point Planning. After completing this tutorial, you should understand SAP reorder point planning which is an MRP (Material Requirement Planning) procedure in Consumption Based Planning.

SAP Reorder Point Planning

As the name indicates, SAP Consumption Based Planning (or CBP) has procedures that are based on information about previous material consumption or the historical data. The MRP procedures that come under consumption based planning are:

- Reorder point planning

- Forecast-based planning

- Time-phased planning

The material requirements planning takes place at plant level. The entire stock on the plant is considered for planning irrespective of storage locations. In this tutorial, we will discuss SAP reorder point planning. The reorder point planning consists of two procedures:

- Manual reorder point

- Automatic reorder point planning

In SAP reorder point planning, a reorder point is obtained by calculating a sum of plant stock and firmed receipts. When the stock level falls below the reorder point, a procurement proposal is triggered. The following parameters are important when considering the reorder point:

- safety stock

- average consumption

- replenishment lead time

In manual reorder point planning, both the reorder point and safety stock are maintained manually in the MRP 1 view of a material master record. In automatic reorder point planning, the reorder level and safety stock are calculated automatically by the forecasting program.

How to Use SAP Reorder Point Planning

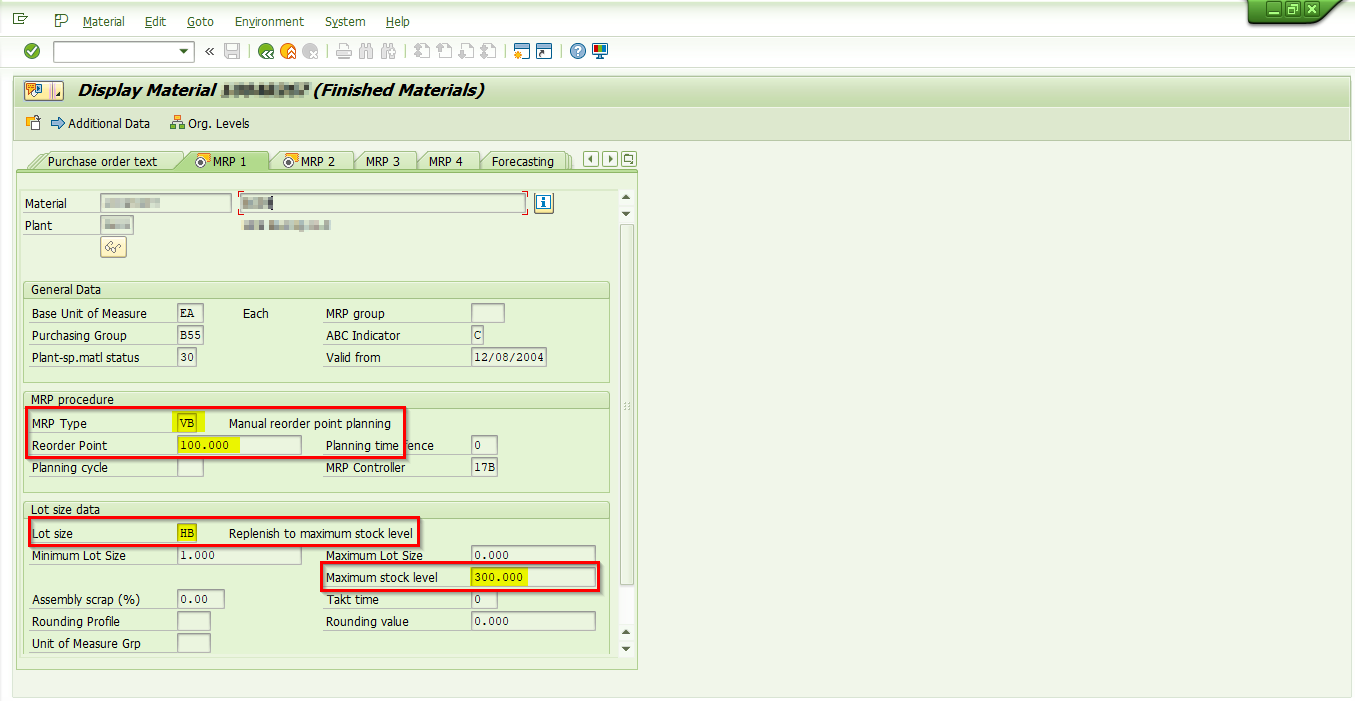

To setup SAP reorder point planning, there have to be settings made at the material master level in MRP views. MRP 1 and MRP 2 views contain fields that are considered for SAP reorder point planning.

- MRP 1 View: MRP type, Reorder Point, Lot Size

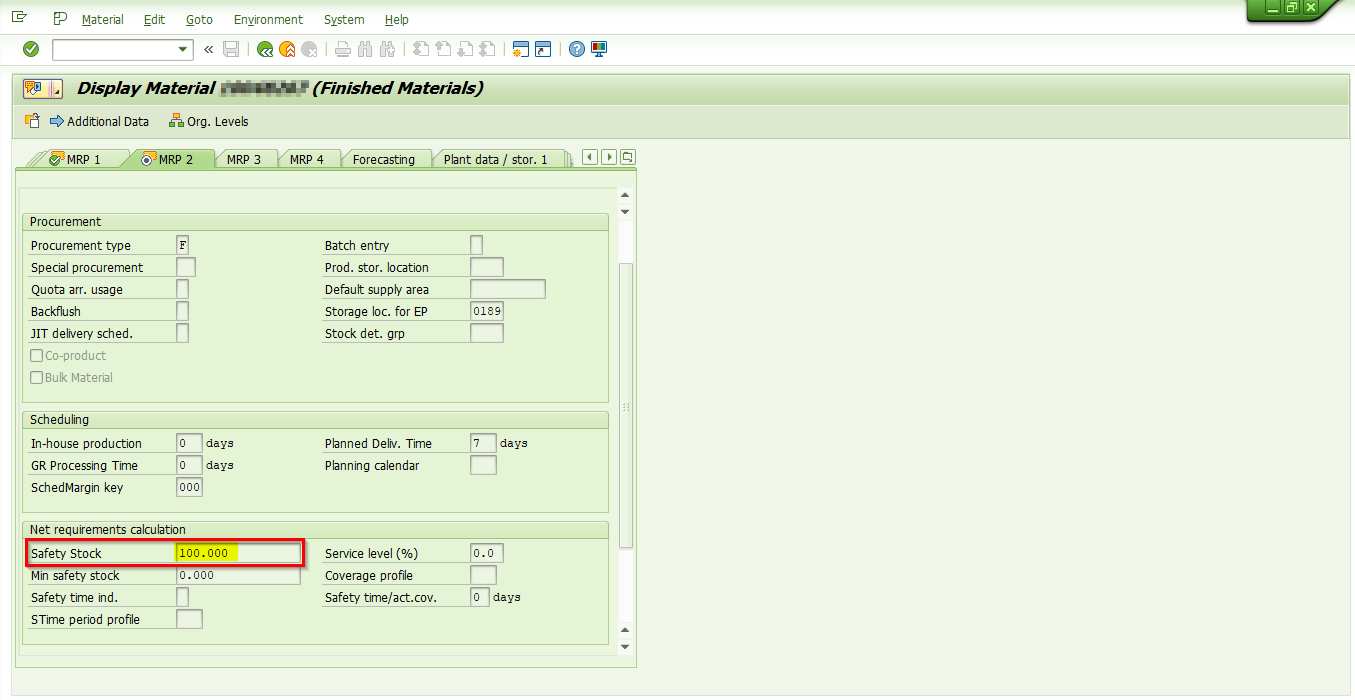

- MRP 2 View: Safety Stock

Here is what these fields mean:

MRP type: VB – Manual reorder point planning; VM – Automatic reorder point planning

Reorder point: A stock value has to be entered in this reorder point field

Lot size: For our illustration, let us maintain “HB – Replenish to maximum stock level”. If we maintain HB, then the maximum stock level field has also to be maintained.

For manual reorder point planning, the MRP type has to be maintained as “VB”. When we enter VB as MRP type, then SAP system would display a message telling us to maintain the reorder point. The reorder point has to be maintained in the specified field.

Then, the lot size plays an important role in procurement proposal. Lot size defines the quantity of the order that has to be placed. In our example, the lot size is maintained as HB – replenish to maximum stock level, so the maximum stock level field has also to be populated with the required stock value. The system will then create orders to replenish stock up to this maximum level.

In MRP 2 view, the safety stock field has to be populated. Safety stock is the minimum stock level that is acceptable for a material. It is defined by business requirements. Now, let us view this material in stock/requirements list transaction (MD03).

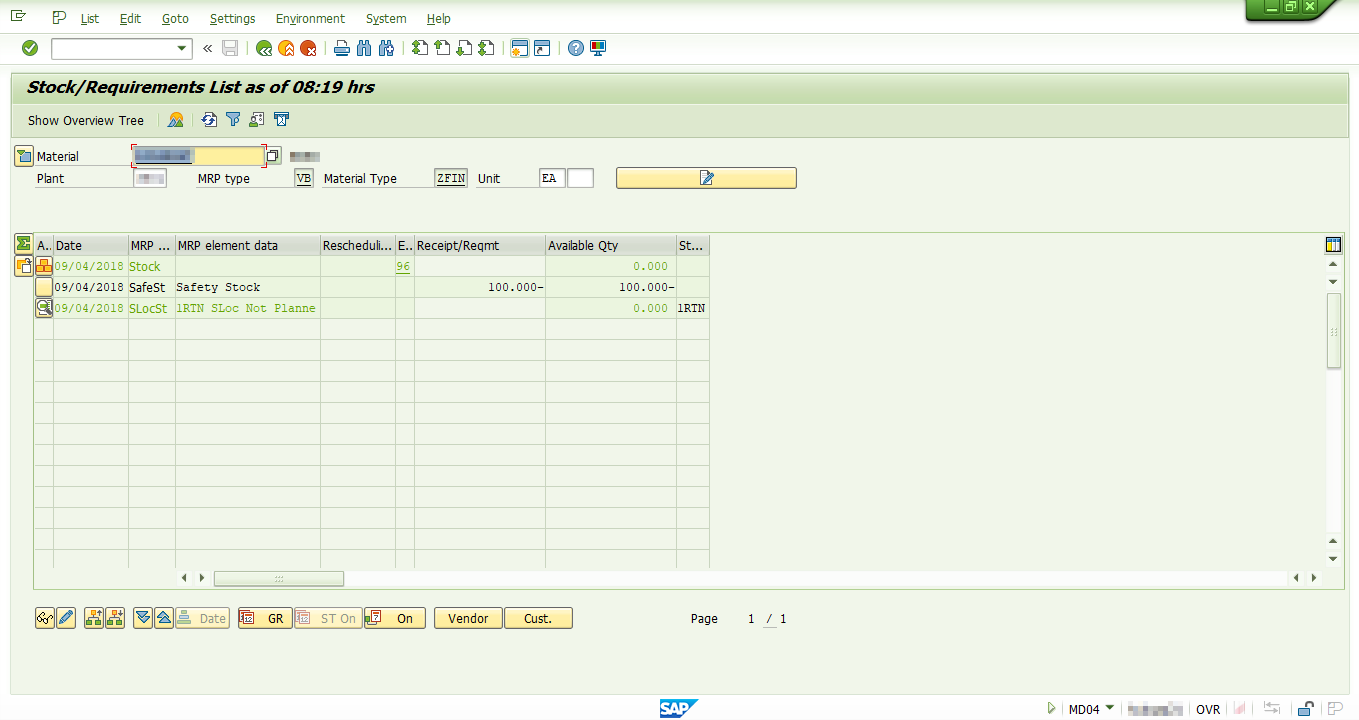

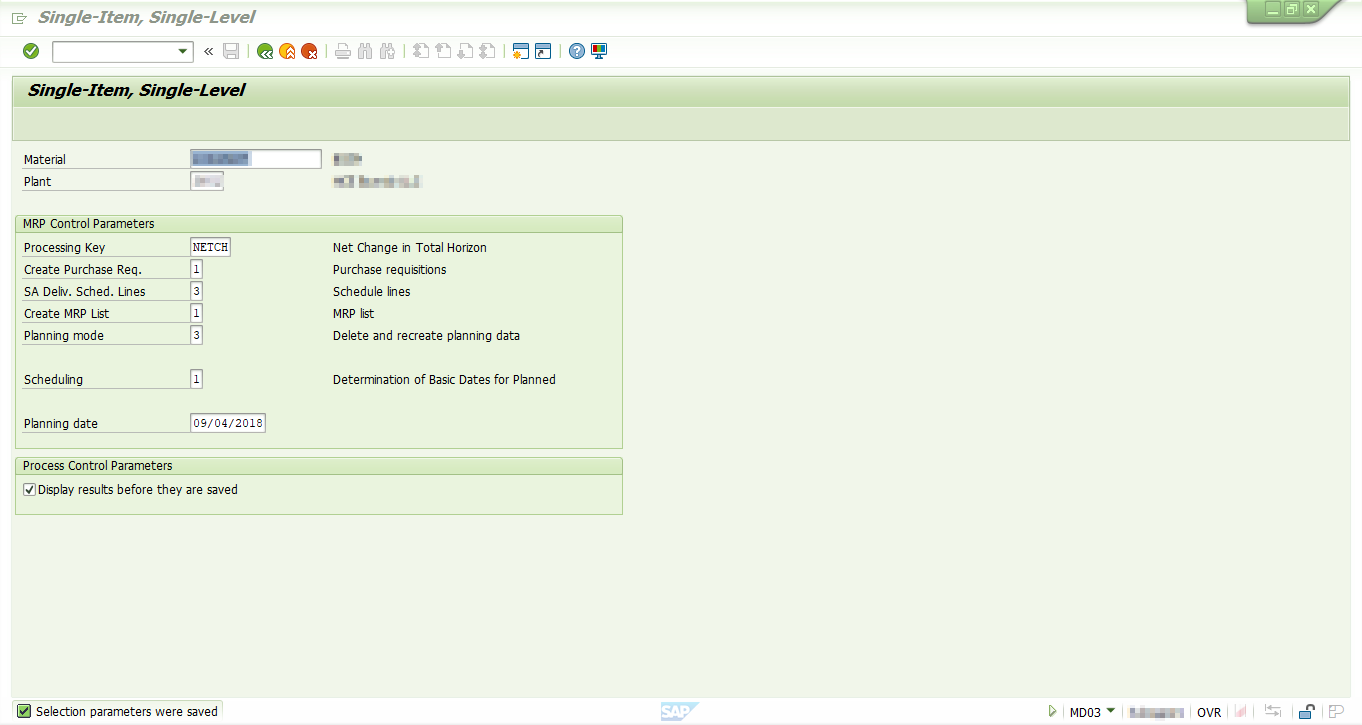

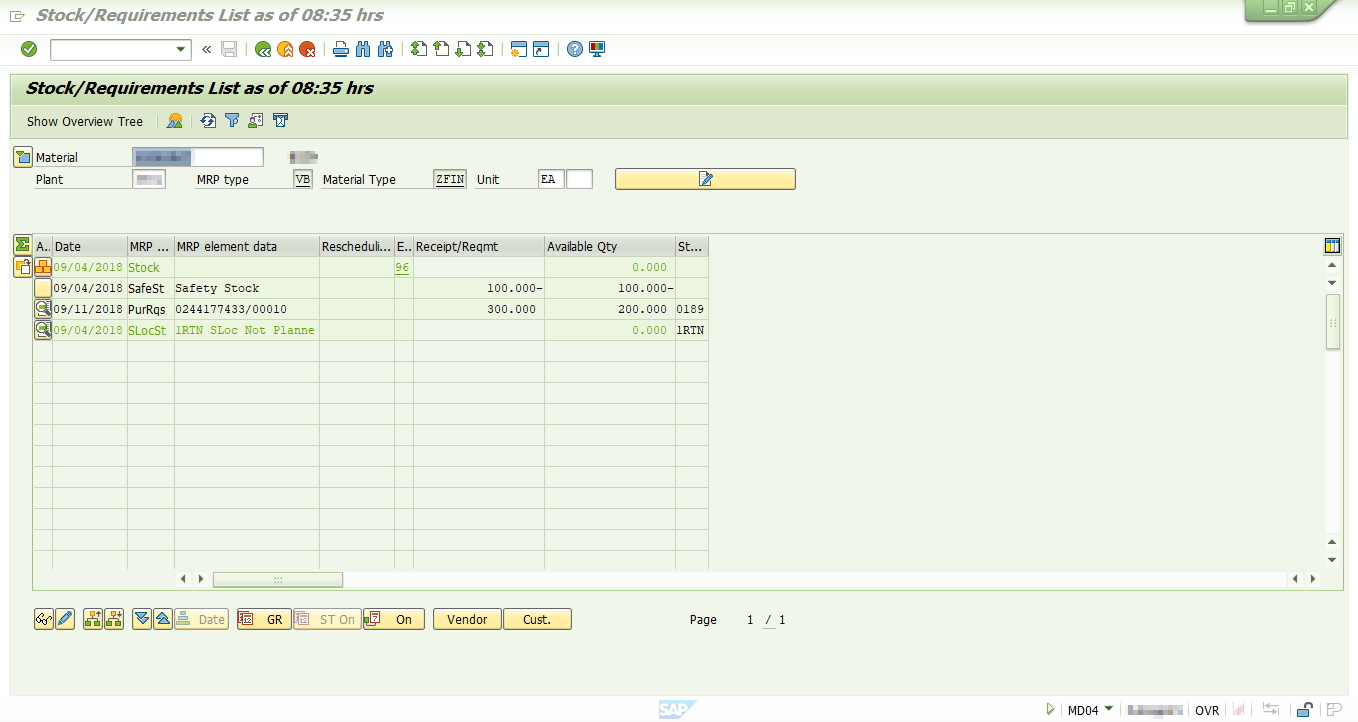

In the above figure, the stock/requirements list is shown. The available stock level is 0.000 at plant level. The safety stock for this material is 100.000 which is also shown. Let us now run MRP at plant level for this material.

The stock/requirement list shown above now contains two lines with the safety stock and a purchase requisition. As the stock level has fallen below the reorder point, when the MRP run was carried out, the system triggers procurement proposal as a purchase requisition. When you look at the image, the purchase requisition quantity is 300, which is the maximum stock level maintained at MRP 1 view of the material master record. This purchase requisition would then be converted to a purchase order by the procurement department When we place a purchase requisition, the expected quantity would first be kept as safety stock, and then the stock would be kept as available stock.

—

Did you like this SAP MM tutorial? Have any questions or comments? We would love to hear your feedback in the comments section below. It’d be a big help for us, and hopefully it’s something we can address for you in improvement of our free SAP MM tutorials.

Navigation Links

Go to next lesson:

Go to previous lesson: SAP Material Status

Go to overview of the course: SAP MM Training

Hi ,

I want to know how manual reorder point works , what type of data to fill in MM.

and what point PR is Generated in system?

how was the qty in the PR computed? if there is stock of 50 qty will it re-order for 300 or 250 ?

I would like to understand how safety time works, and especially how it relates to VSF entries for material in SAP.

did you find your answer?

If Stock is 100, would reorder kick in, or does it need to drop to 99 to activate?