SAP source determination is a process that allows the buyer to discover the most suitable source of supply while creating a purchase requisition. This source of supply refers to a vendor account. These preferred vendors for materials are set as master data elements called source lists. During purchase requisition creation, if the source determination indicator is set in the header, then SAP looks for a source list for each item in the requisition. In this tutorial we explain the SAP source list and discuss its influence in the process of source determination. This article is provided as part of our free online SAP MM training.

The SAP source list comprises the list of vendors that should be sourced for a material in a particular plant and for specific period of time. The list is created by material and plant combination and specifies the validity period during which the vendor is the preferred source of supply. It also identifies whether the source is fixed, blocked or relevant to material requirements planning (MRP). In the following sections, we first identify the prerequisites to enforcing source list functionality. Then we walk through the fields of the source list master record. Then we itemize the various methods for creating a source list and walk through the creation of a record by illustrating an example. Finally, we demonstrate how the source list is used during purchase requisition creation.

SAP Source List Prerequisites

Although an SAP source list is a master data record that can be created at any time by an authorized user, there are certain settings that enforce the requirement to use a source list. The source list can be set as mandatory at the plant level through configuration. It can also be required at the material level through a material master data setting.

Require Source List at Plant Level

Through customizing we can define that a source list record must exist for all materials belonging to a certain plant. To define the source list requirement at plant level, use transaction code OME5 or use the customizing path below in transaction code SPRO:

Materials Management - Purchasing - Source List - Define Source List Requirement at Plant Level

Search for the plant that requires a source list to be maintained and check the tickbox in the Source list column. Check boxes for additional plants as needed. In our example below, plant 1200 - Head Office requires a vendor to be identified in a source list in order for a purchase order to be created:

Hit Save to save the source list requirement for the plant(s).

Require Source List at Material Level

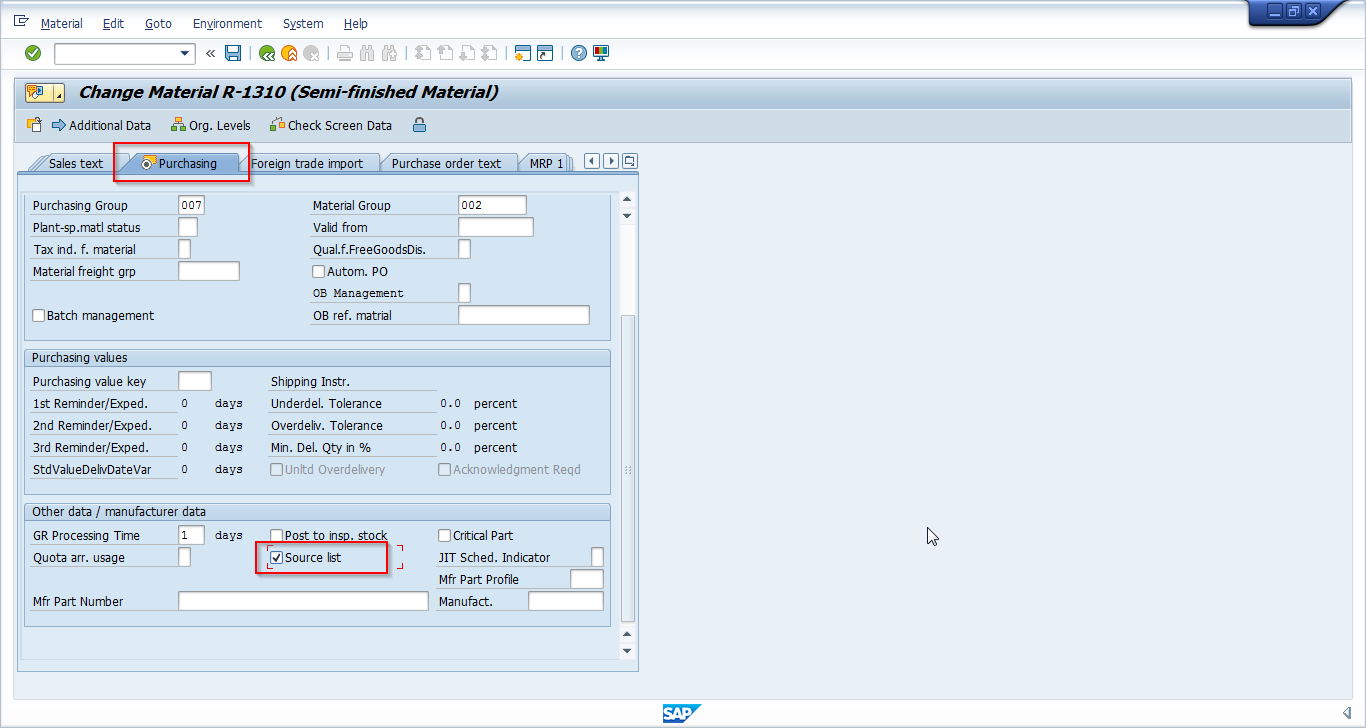

To require a source list only for specific materials, forego the plant level configuration and maintain the source list requirement at the material level. This can be set in the material master record as an indicator that enforces a source list to be maintained in order to create a purchase order for that particular material. Pull up the applicable materials in change mode via transaction code MM02. Then click the Purchasing tab and tick the Source list indicator as demonstrated below:

SAP Source List Master Record Fields

Now that we have designated that a source list is required at various levels, let’s walk through the fields of a source list master data record:

Valid from/Valid to: These fields contain the validity date range that specifies when a vendor will be the source of supply for the material and plant combination.

Vendor: Specify the master record number of the source of supply for the material during the validity period.

POrg: Enter the purchase organization to be maintained along with vendor number as key fields.

PPl: If the material is to be procured from within the organization, maintain the procurement plant number in this field. This field will be maintained for materials with stock transfer type.

OUn: This field holds the preferred unit of measure for orders from this source of supply.

Agmt: If there is an outline agreement (either a contract or a scheduling agreement) existing with the vendor, enter it in this field.

Item: This field references the item number on the outline agreement, if applicable.

Fix: This indicator is to be set if the vendor is the preferred source of supply for the material and plant combination.

Blk: If a particular vendor is to be blocked from supplying the material for a specified time, then this indicator is to be set. No purchase order or purchase requisition can be created with this vendor.

MRP: This field is used to indicate whether the material is relevant to material requirements planning.

For an example source list master record displaying each of these fields, see below:

Create SAP Source List

An SAP source list master record can be created in the below ways which we discuss in the following sections:

- Manual Creation

- Creation Within an Outline Agreement

- Creation Within a Purchasing Info Record

- Automatic Creation

Manual Creation

Manually creating a source list record is suitable when you need to create a single new record or maintain additional lists within an existing record. To illustrate, let’s assume a company needs to buy ethernet coaxial cables externally. An appropriate vendor has been determined based on price, delivery time and other factors. The employee who creates purchase requisitions should maintain a source list for the material, linking it to the supplier. Let’s examine how to create a source list manually for this scenario.

| Menu path | Logistics - Materials Management - Purchasing - Master Data - Source List - Maintain |

| Transaction code | ME01 - Maintain |

In the initial screen of transaction code ME01 enter the material number and plant. In our example below, material number DPC1001 represents the ethernet coaxial cables for which we are creating the source list:

Hit Enter. In the maintain source list overview screen, enter the Valid from, Valid to, Vendor, POrg and OUn fields as described in the previous section. Then, press Enter then Save to create the source list as outlined below:

Creation Within an Outline Agreement

While creating an outline agreement, adopt the line of the agreement automatically to a source list. In the outline agreement overview screen, select the item for which a source list is to be created and select Item > Maintain Source List from the menu bar as shown below:

Creation Within a Purchasing Info Record

A source list record can be created when creating or changing a purchasing info record. In the info record screen select Extras > Source List from the menu bar as shown below:

Automatic Creation

Alternatively, a source list record can be generated automatically for every info record or every outline agreement, selecting for a single material or several materials.

| Menu path | Logistics - Materials Management - Purchasing - Master Data - Source List - Follow-On Functions - Generate |

| Transaction code | ME05 - Generate |

In the initial screen of transaction code ME05, specify the material(s) and plant(s) as well as date range for which to generate the source list. Click Execute to show the source lists to be generated. This can be done in test mode prior to actual execution.

Create Purchase Requisition Using Source List

Once the source list is created, a purchase requisition can be created using the record. Let’s create a requisition to purchase 100 meters of ethernet coaxial cable, using the source list from our example.

| Menu path | Logistics - Materials Management - Purchasing - Purchase Requisition - Create |

| Transaction code | ME51N - Create |

Enter all the relevant information to create the purchase requisition, including Material, Quantity, Delivery Date and Plant. You now have a couple options to retrieve the vendor from the source list.

First, you can click the Source of Supply tab in the item detail area. Then click the Assign Source of Supply button to assign the vendor from the source list record.

Otherwise, set the Source Determination tickbox at the header level to automatically selects the source list record.

Further, if the source list is marked as relevant for MRP then this material will be considered during the planning run. In this case the purchase requisition will be created automatically with the assigned source list records and no further action is needed from the user.

—

Did you like this SAP MM tutorial? Have any questions or comments? We would love to hear your feedback in the comments section below. It’d be a big help for us, and hopefully it’s something we can address for you in improvement of our free SAP MM tutorials.

Navigation Links

Go to next lesson: SAP Evaluated Receipt Settlement

Go to previous lesson: SAP Blanket Purchase Order

Go to overview of the course: SAP MM Training

That’s so perfect I appreciate tje effort. I hope you do a tutorial focused on MRP from A to Z within MM module and how to use it of both sides using it and configuring it. Thanks for the the tutorials again.

Can you please provide a link for download this as pdf

We buy some intercompany SKUs but we are going to sell that part of company and the SKUs will be changed to third party. I have been told that there is a checkbox that I can click to change the status of the material from intercompany to thirdparty to avoid setting up new SKUs in the system. Can you please advise if there is checkbox or any way to do that?

Thank you very much for the content. Very comprehensive content

Can there people multiple vendors on the source list?

It has been some time since Iast used SAP and MR2 for business. I am currently starting to update my training. Thank you for having this training module available.

Hi,

I am getting an error while creating PO.

Error -

Material C420 not included in source list despite source list requirement.

Please help waiting for reply.

you need to create source list first by using ME01 t-code or untick source list in material master.

the standard source list funcionality from SAP will also work in Ariba system?

Is it possible to have multiple Fixed suppliers in the same period. Looking for a function to identifify qualified suppliers and in some cases we need 2 or more qualified suppliers. Other suppliers are listed durig the supplier qualification process and therefore the fixed supplier indicator is not needed selected.

what is the T-code to view source list of multiple parts.

The purpose is to indicate the parts, which source list is missing, so that can be created.