Welcome to the next tutorial of SAP PM course! In this tutorial, you will learn about SAP Serial Numbers and their use for serializing equipment in plant maintenance. We will show how to create serial number profile, assign it in a material master record, and create a new serial number attached to equipment.

Welcome to the next tutorial of SAP PM course! In this tutorial, you will learn about SAP Serial Numbers and their use for serializing equipment in plant maintenance. We will show how to create serial number profile, assign it in a material master record, and create a new serial number attached to equipment.

SAP serial numbers functionality helps managing serialized stock. It is mainly focused on tracking of inventory. Serial number is the number which is assigned apart from the material number in SAP MM in order to differentiate between individual pieces and other material items. The combination of a material number and a serial number is always unique. The SAP serial numbers are used in following areas:

- Inventory Management

- Sales Order

- Plant Maintenance

- Production Planning

Serializing a piece of equipment enables the equipment to be managed from inventory prospective. When a serial number is assigned to equipment, the equipment is linked with a material and serial number meaning that you can use material serial number to manage the equipment from plant maintenance perspective.

To serialize the equipment, a serial number profile must be configured in customization of plant maintenance.

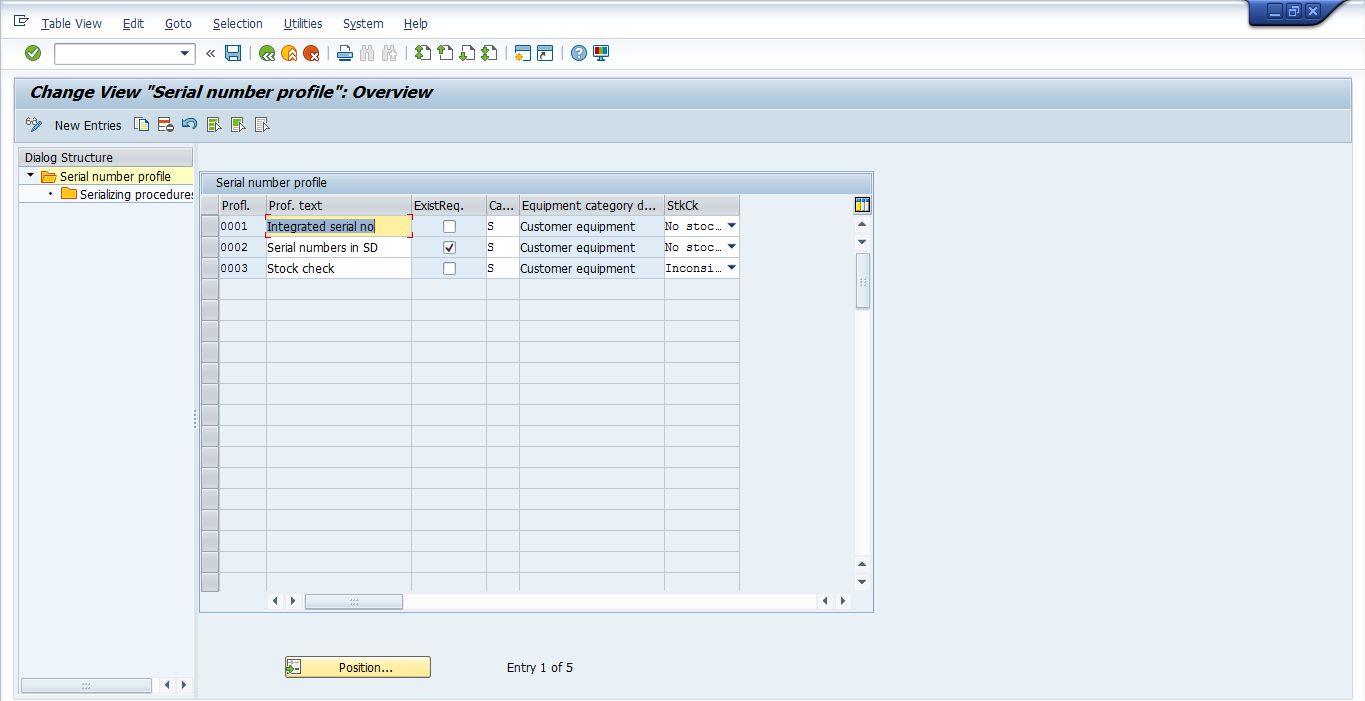

Define SAP Serial Number Profile

SAP serial number profile is a 4-digits number under which defines the conditions of operation for the assignment of serial numbers to equipment. It is configured in the following menu node of SPRO transaction:

Plant Maintenance and Customer Service > Master Data in Plant Maintenance and Customer Service > Technical Objects > Serial Number Management > Define Serial Number Profiles

In SAP serial number profile, you define 4-digits profile number with a corresponding description. Also, there are the following parameters:

- Serial Number Existence Requirement Indicator: This indicator determines serial number entered for transaction needs to be created first as master record. If you set this indicator, then the serial number must be created as a master record first in the system. If not, then the serial number directly can be created during business transaction.

- Equipment Category: Equipment category according to their use. The equipment category which the system should propose for the automatic assignment of serial numbers in the case of equipment master records.

- Stock Check for Serial Numbers: This indicator determines if stock check during serial number assignment needs to be performed or not.

Assign SAP Serial Number Profile to Material Master Record

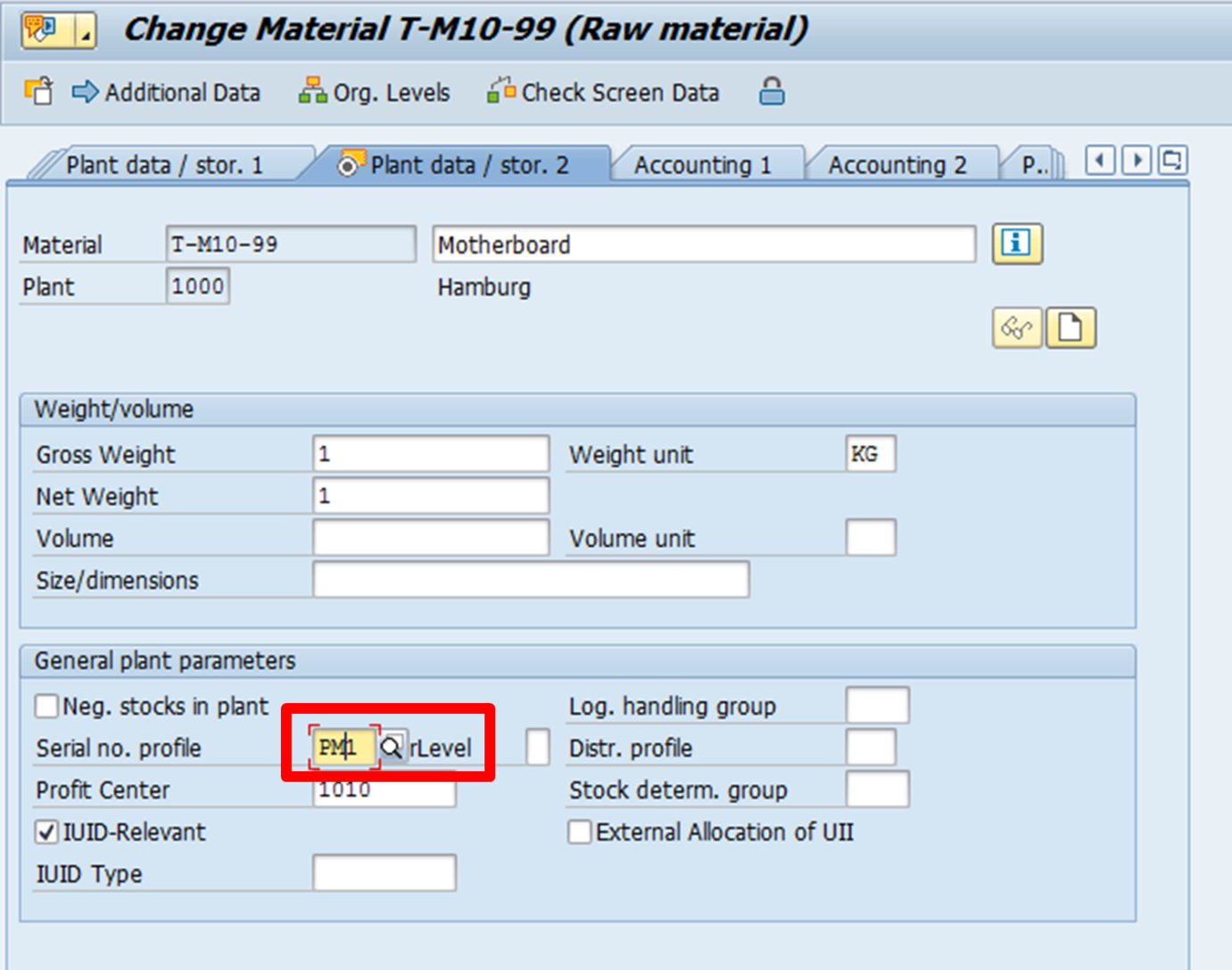

SAP serial number profile has to be assigned to each material master to be serialized. You can assign separate serial number profile to material for each plant because assignment of SAP serial numbers profiles to materials is done at the plant level in material master record.

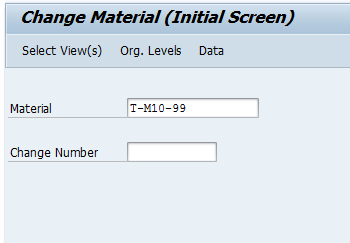

Navigate to the following path in SAP Easy Access menu or start the transaction MM02 directly:

Logistics > Material Management > Material Master > Material > change > Immediately MM02

The following screen will appear where you enter MM02 transaction. Enter the material number and click Select Views button.

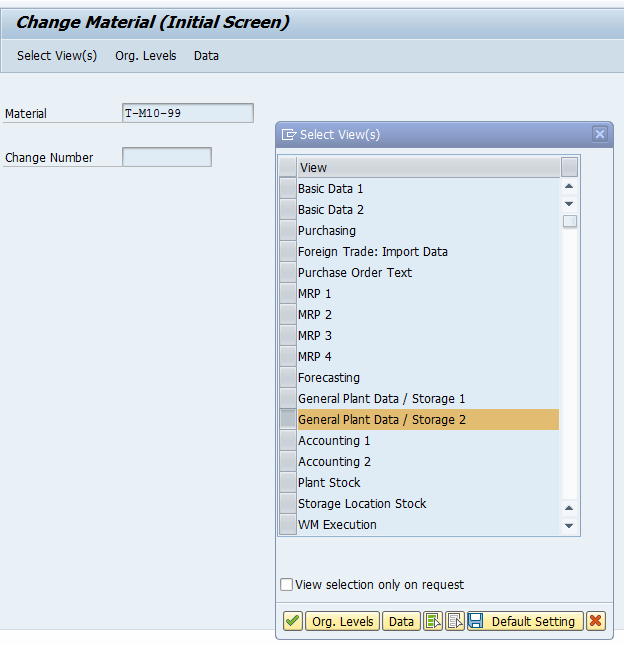

Choose Plant data/storage 2 and press Enter.

On change material screen, enter the serial number profile which you have configured in the customization.

Click on Save and SAP serial number profile will be assigned to the material master record.

Create SAP Serial Numbers

SAP serial numbers can be created with a length of 18 characters and support both numeric and alphabetical characters. Serial numbers can be created manually or automatically. Serial number master record can be created prior to the business transaction. If need to create an individual serial number, you can use the transaction IQ01 and if you need to create several SAP serial numbers together use IQ04 transaction.

The following information is contained in SAP serial number master:

- Status information: System status provides you with the information about the current status of SAP serial number. You can also configure a custom status as user status for more information and control over SAP serial numbers.

- Stock information: It provides the information about plant and storage location of material/equipment.

- Serial number history: It provides the past information about serial number master.

To create SAP serial number, follow these steps. Navigate to the following node in SAP Easy Access menu:

Logistics > Plant Maintenance > Management of technical objects > Serial Numbers > IQ01 – Create

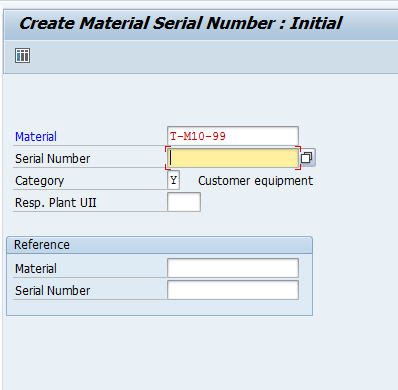

On the initial screen of IQ01 transaction, enter following details:

| Material Number | <Material Number> |

| Serial Number | Enter serial number if you have one. If you don’t have one, the system will assign one. |

| Category | < Equipment category> |

Press Enter to continue.

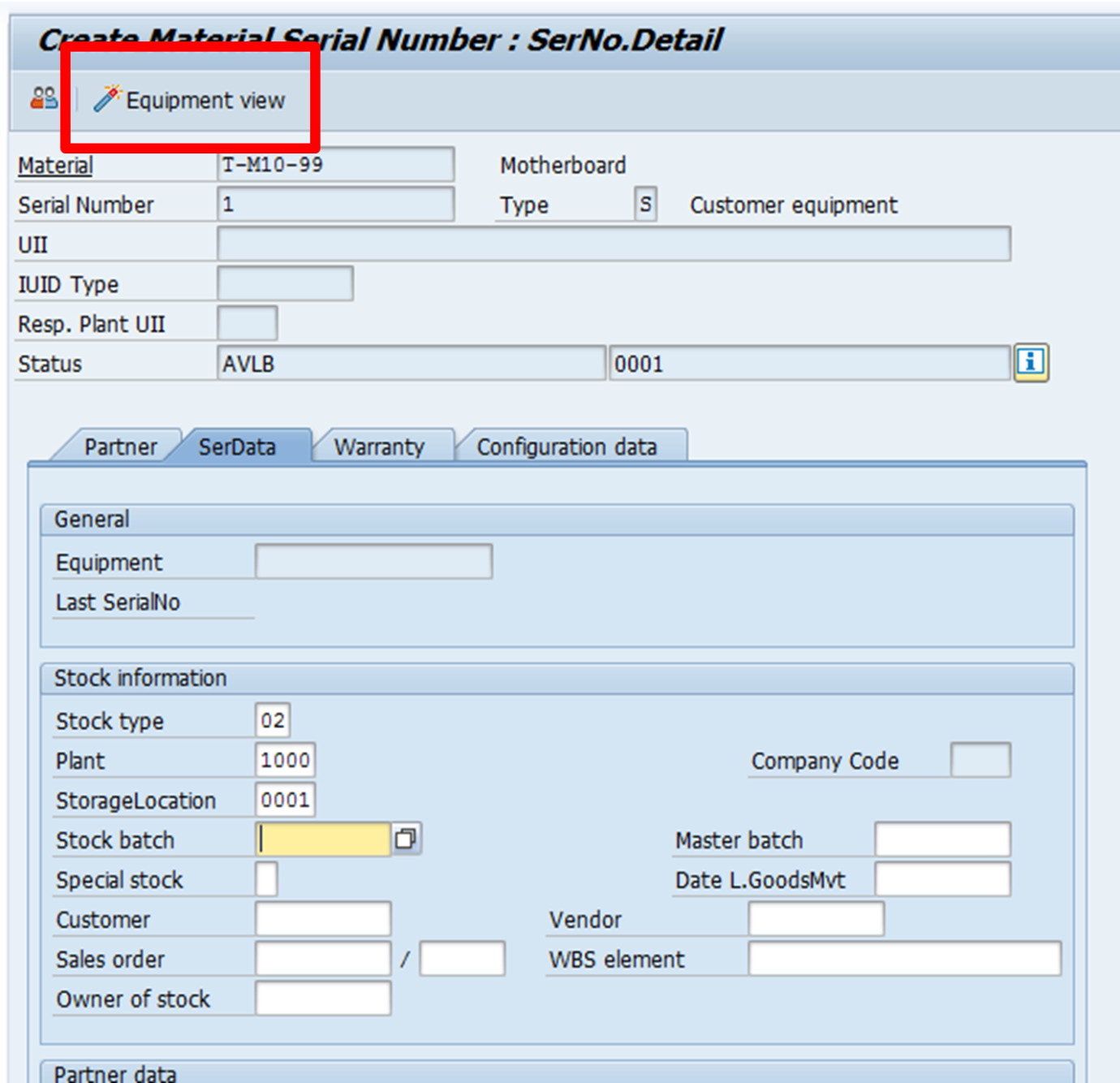

You can enter SAP serial number specific data and click on Equipment view to create an equipment view.

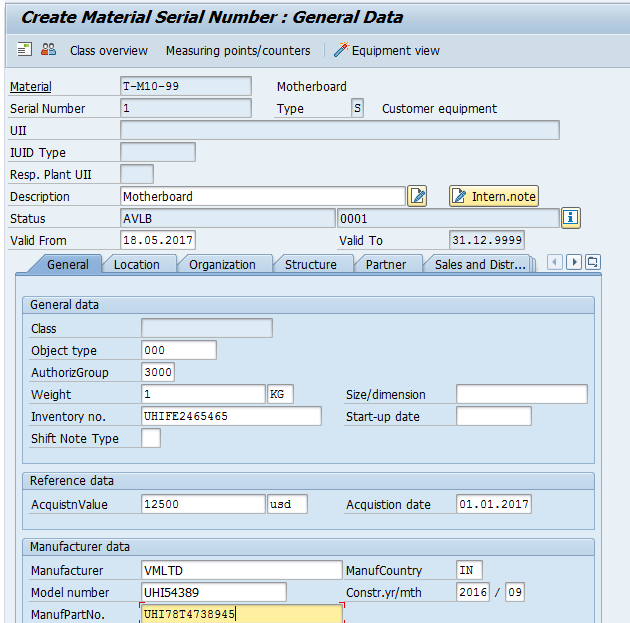

Enter the data related to the equipment and click on Save icon. SAP serial number including the equipment view will be created.

The created equipment view can be also changed and displayed. Start the following transaction in SAP Easy Access menu:

Logistics > Plant Maintenance > Maintenance of technical object > Equipment > IE02 - Change

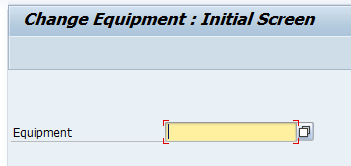

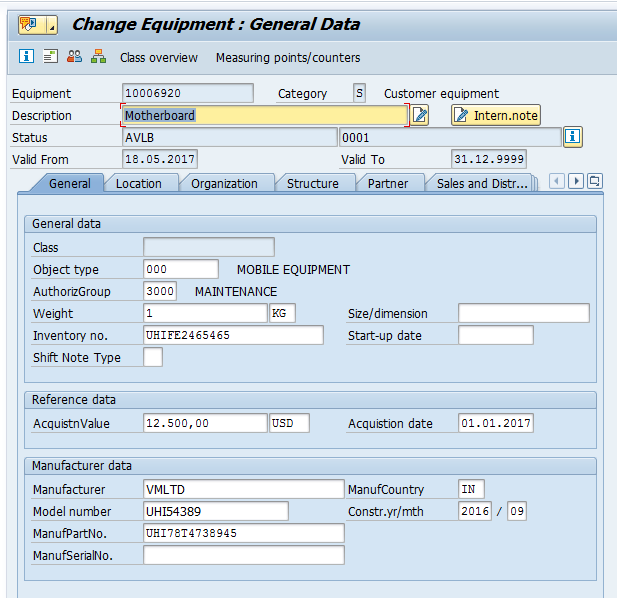

The following screen will appear.

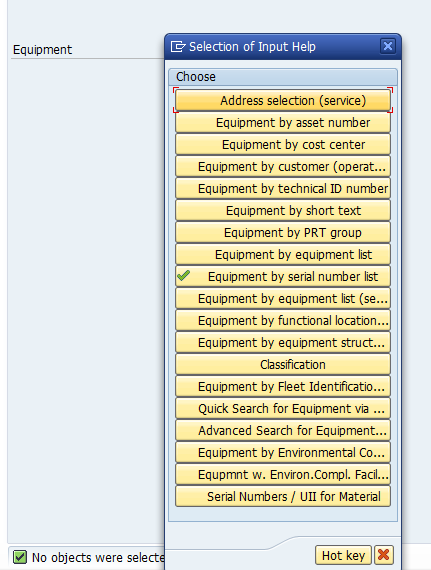

Click F4 and from the selection of input help option select Equipment by serial number list.

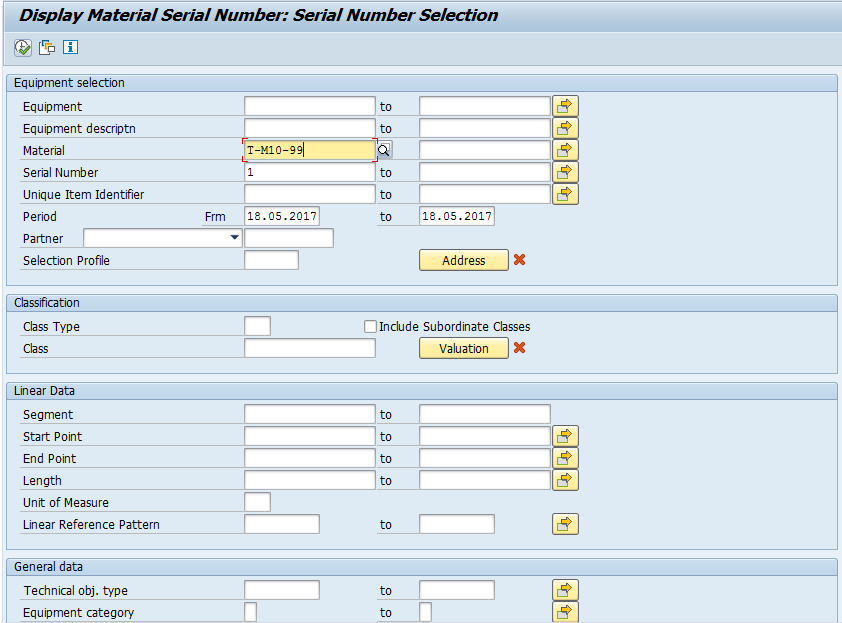

The following screen will appear where you need to enter details like material and serial number in the input fields.

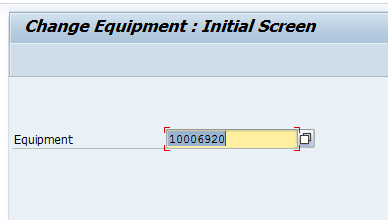

Press Execute button the equipment number will found and populated in the corresponding field as shown below.

Press Enter to change the equipment master record.

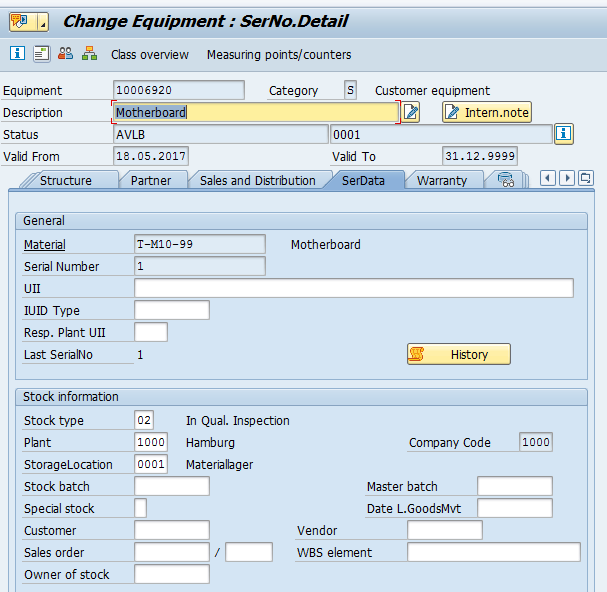

If you navigate to Serial Data tab, you can view SAP serial number of this equipment.

—

Did you like this tutorial? Have any questions or comments? We would love to hear your feedback in the comments section below. It’d be a big help for us, and hopefully it’s something we can address for you in improvement of our free SAP PM tutorials.

Navigation Links

Go to next lesson: SAP Breakdown Maintenance Process

Go to previous lesson: SAP PM Bills of Material

Go to overview of the course: SAP PM Training

dear sir

Myself Yuvaraj this site is good for learning but if u add video lectures to this it will be very good so i can relate the steps u said above. plzz kindly add the videos for better understanding.

from where i can check my product serial number which i already assign in material ,

IQ03 or IQ09 transactions

Good tutorial!

Is a material type can be restricted to a serial number profil? Ex: Material Type UNBW restricted to profil 0003 - Stock Check?

Thanks!

passando da IQ09 accedo ad IQ03 .Da IQ03 si può aanche passare in modifica, come posso inibire questa possibilità?

from IQ09 I access IQ03. From IQ03 it is also possible to change it, how can I inhibit this possibility?

Do you have any process as how to do the stock management with serial numbers?

thank you very much.

Every step was very clear.

Can I use a serial number with equipment in sales order ?

Wowww this site is incerdible 🙂

Hello Friends .Can someone suggest that how can upload bulk serial no without using Iq02.

Or any other t code which i can use for manufacturing serial no after do the GRN.

How to update the serial no. in Objects tab..IW32 screen. Existing line item (equipment no.) is non-editable mode. How to do it? There were no serial data updated in IE02 screen. Material and Serial number updated in IQ01. Kindy advise.

Very nice document one more question, how to add more serial numbers into same material and equipment?

Very good content.. there should be a discussion forum also

Thanks for this amazing doc. Just wondering in the refurb order, where do i see the serial number? Is it the object tab in th eheader?

S