Welcome to the tutorial on SAP reduction strategy. This tutorial is part of our free SAP PP training. SAP reduction strategy is applied to an order when lead time (scheduled dates) of an order is greater than basic dates in the order. SAP reduction strategy reduces the lead time of an order by applying reduction measures.

Welcome to the tutorial on SAP reduction strategy. This tutorial is part of our free SAP PP training. SAP reduction strategy is applied to an order when lead time (scheduled dates) of an order is greater than basic dates in the order. SAP reduction strategy reduces the lead time of an order by applying reduction measures.

SAP Reduction Strategy

Before getting into details of SAP reduction strategy, let’s understand how scheduling is happening in SAP. Please refer the previous tutorial SAP PP Scheduling.

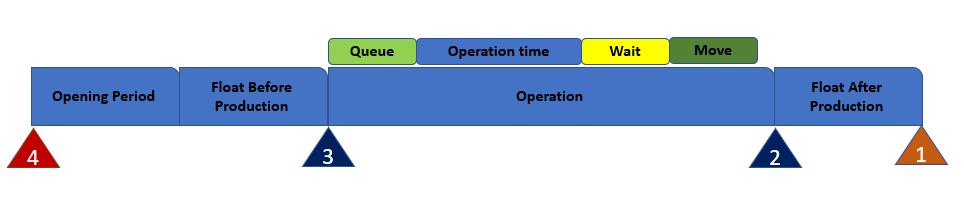

When SAP system tries to schedule a production order, the following dates are determined:

- Basic start date

- Basic finish dates

- Schedule start date

- Schedule start time

- Schedule finish date

- Schedule finish time

In backward scheduling, the system calculates basic finish date from the requirement date.

Here is the explanation of the time points on the diagram above:

- Requirement date/Basic finish date

- Schedule finish date/time

- Schedule start date/time

- Basic start date

Total operation lead time = inter-operation times (queue + wait + move) + activity times in all operations.

Queue time is defined in a work center and also routing:

- Standard queue time

- Minimum queue time.

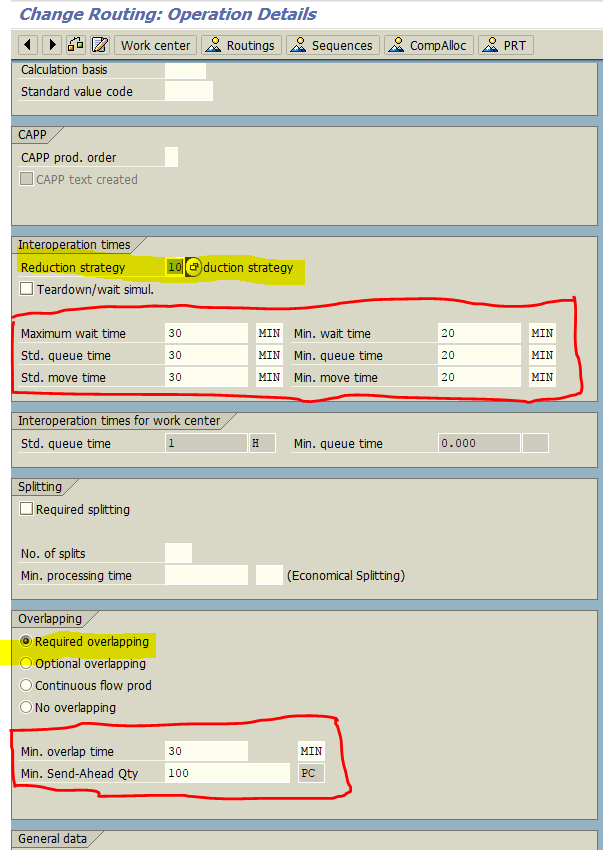

Wait time and move times are defined in routing operation details:

- Standard move time and minimum move time

- Standard wait time and minimum wait time.

The reason is wait time is related to the process can be seen on the example of drying time. After certain time before moving the material to next work station, the material must be dried for 30 mins. This is known as wait time which cannot minimized or ignored.

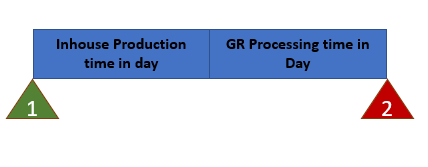

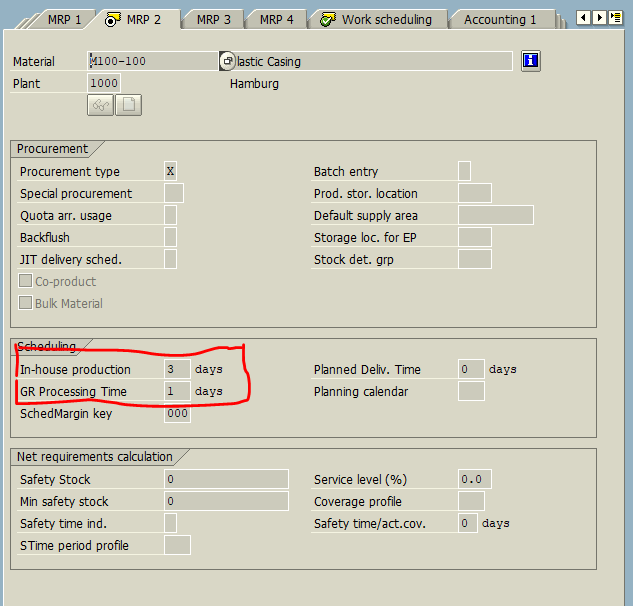

Basic start dates and finish dates are calculated based on material master data.

- Basic start date

- Basic finish date

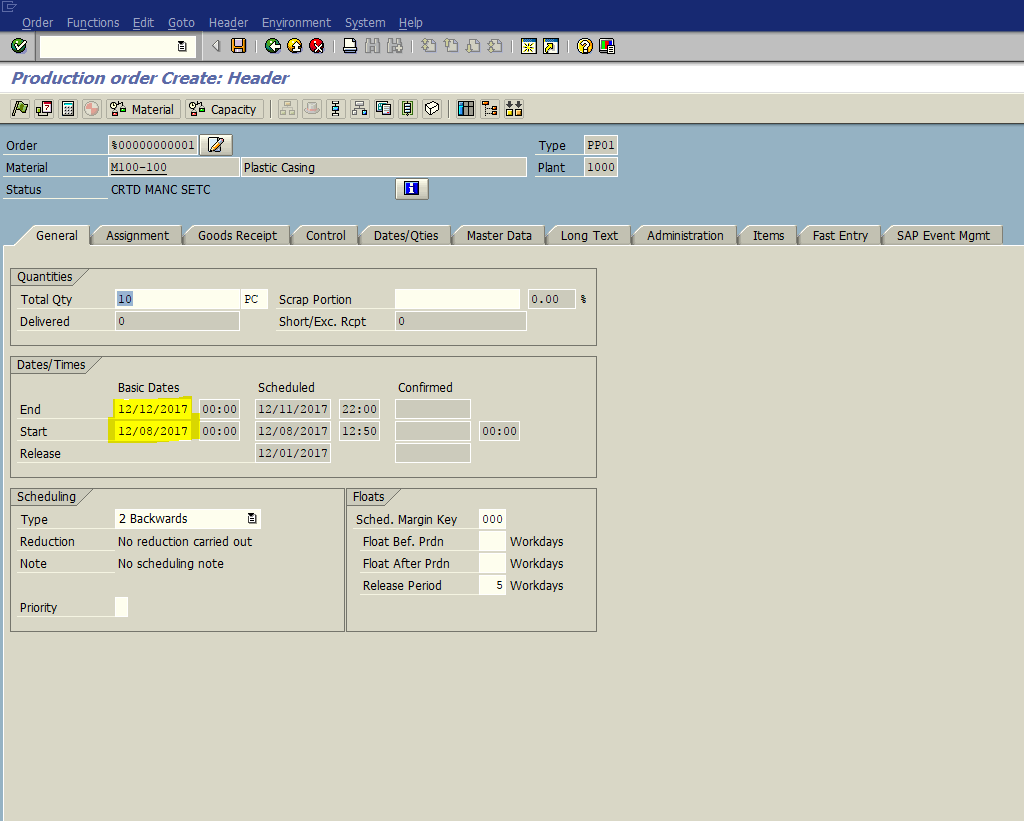

When we create a production order the system calculates basic start date as follows:

Basic start date = Basic finish date – (GR Processing time (1 day) + In-house time (3 days)) =

= 12-DEC-2017 – (1 + 3) = 12-DEC-2017 – 4 = 08-Dec-2017.

Similarly, schedule start date and finish dates are calculated from the basic finish date.

Schedule Finish date = Basic finish date – (GR Processing time + Schedule after production) =

= 12-Dec-2017 – (1 +0) = 11-DEC-2017.

Schedule Start date = Schedule Finish date – (Total operations lead time + Float before production).

When schedule start date is calculated before basic start date, the system tries to perform the following scheduling approach and tries to adopt schedule dates within basic dates.

- When schedule start date lies before basic start date, the system starts today scheduling, i.e. it sets basic start date as current date and tries to schedule and calculated basic finish date and schedule dates.

- If the system finds schedule finish dates lies after basic finish dates after today scheduling, it applies minimum time (wait, queue and move time) from routing.

- If the system finds schedule finish dates lies after basic finish dates after scheduling with minimum inter-operation time, it tries to apply “Reduction strategy” in six steps.

We can define our own reduction strategy in customization. In all 6 steps, the system tries to reduce the inter-operation time gradually except wait time in order to adopt the schedule dates within basic dates. As explained previously, wait time cannot be reduced as it is related to the process. The reason is wait time cannot be reduced is as it is related to the process, for example drying time. After certain time before moving the material to next work station the material must be dried for 30 mins.

Overlap Time and Minimum Send Ahead Quantity

The system also tries to reduce the operation time by means of overlap time which means next operation starts before the previous operation has finished when minimum send ahead quantity is produced. The lead time of an operation also reduced by splitting the operation defined in a work center.

SAP Reduction Strategy Example

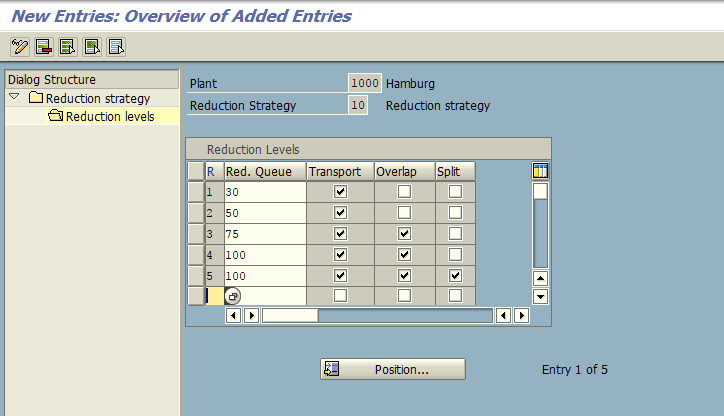

Let’s look into the following SAP reduction strategy defined in IMG.

As per this reduction strategy, it applies reduction level while it finds schedule dates lying within basic dates.

| Reduction Level | Action |

| Reduction 1 | Reduce the queue time by 30% and reschedule. |

| Reduction 2 | Reduce the queue time by 50% and completely reduce move time, then reschedule. |

| Reduction 3 | Reduce the queue time by 70%, completely reduce move time and apply operation split, then reschedule. |

| Reduction 4 | Reduce the queue time by 100%, completely reduce move time and apply operation overlap, then reschedule. |

| Reduction 5 | Reduce the queue time by 100%, completely reduce move time, apply operation overlap and also apply operation split, then reschedule. |

If SAP system is unable to fit schedule dates within basic dates even after reduction strategy, it provides a scheduling log and schedules the order as per actual dates.

This example of SAP reduction strategy is explained without screenshots as some of the screens may be difficult to understand for beginners.

Let’s say for manufacturing product “A”, the following settings are maintained in MRP 2 view of a material master.

| Field | Value | Unit of Measure |

| In-house production time | 2 | Days |

| GR processing time | 1 | Days |

| Schedule margin key | FBP – 1 Day

FAP – 1 Day Release period 1 day |

Days |

Also, the following settings are maintained in a routing.

| Field | Time | Unit |

| Machine time | 60 | Min/100 KG |

| Standard queue time | 24 | Hours |

| Minimum queue time | 12 | Hours |

| Standard wait time | 24 | Hours |

| Minimum wait time | 18 | Hours |

| Standard move time | 30 | Mins |

| Minimum wait time | 10 | Mins |

Let say we have only one resource used to produce Product ‘A’ available all days (working day) and its available time (capacity) is 24 Hours/day. When we create an order with requirement dates of 30-JAN-2018 for 3000 KG for the product ‘A’, the system calculates dates as follows.

Basic Dates Calculation

Basic Finish date = Requirement date = 30-Jan-2018

Basic Start date = Basic finish date – (GR processing time+ In-house production time) =

= 29-Jan-2018 – (2+1) = 26-Jan-2018

Schedule Dates Calculation

Schedule Finish date = Basic Finish dates – (Float after production) =

= 30-Jan-2018 – 1 day = 29-Jan-2018 at 00:00 hours

Schedule Start date = Schedule finish date – (Total operation time + Float before production + Inter-operation time)

Total operation time = (60 mins /100 Kg) * 3000 Kg = 1800 mins

Inter-operation time (Considering standard time) = Queue + Wait + Move =

= 24 hours + 24 hours + 30 mins = 2910 mins

Float before production = 1 day = 24 hours = 1440 mins

Schedule Start date = Basic finish date – (1800 + 1440 + 2910) =

= Basic finish date – 6150 mins = 4 days 6 hours 30 min =

= 29-Jan-2018 00:00 hours – 4 days 6 hours 30 min = 25-Jan-2018 18:30 hours

Here, schedule start date does not lie between Basic dates. So, the system tries to apply minimum Inter-operation times instead of standard time.

Inter-operation time (Minimum time) = Queue + Wait+ Move =

= 12 hours + 18 hours + 10 mins = 1810 mins

Schedule Start date = Basic finish date – (1800 + 1440 + 1810) =

= 29-Jan-2018 – (3 days 12 hours 10 minutes) = 25 Jan-2018 11:50

After using minimum inter-operation time, schedule start dates still does not lie between Basic dates, so the system will try to apply SAP reduction strategy level by level. For every reduction step, the system will reschedule the order. When the system finds that schedule start dates lie within basic dates, it stops reduction and schedules the order.

—

Did you like this tutorial? Have any questions or comments? We would love to hear your feedback in the comments section below. It’d be a big help for us, and hopefully it’s something we can address for you in improvement of our free SAP PP tutorials.

Navigation Links

Go to next lesson: SAP Trigger Points

Go to previous lesson: SAP PP Scheduling

Go to overview of the course: SAP PP Training

very well explained!!

Shouldn’t “In backward scheduling, the system calculates basic finish date from the requirement date.” be “…calculates basic start date…”?

Nice explanation. Thanks for making this tutorial short and clear.